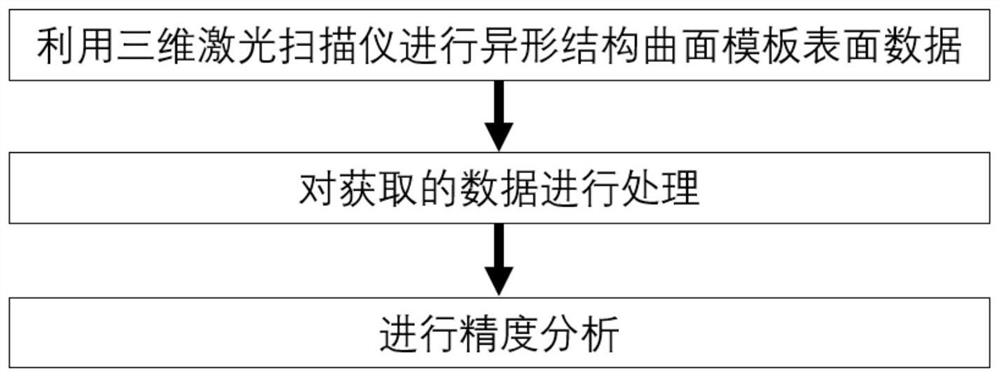

Method for optimizing surface measurement of curved surface template based on three-dimensional laser scanning technology

A three-dimensional laser and scanning technology, applied in the optimization field of surface measurement of curved template, can solve the problems of restricting the accuracy and efficiency of special-shaped curved surface measurement, high professional requirements, low data processing accuracy, etc., to avoid a large number of overlapping, shortening Measure the effect of time, safety and simplicity improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

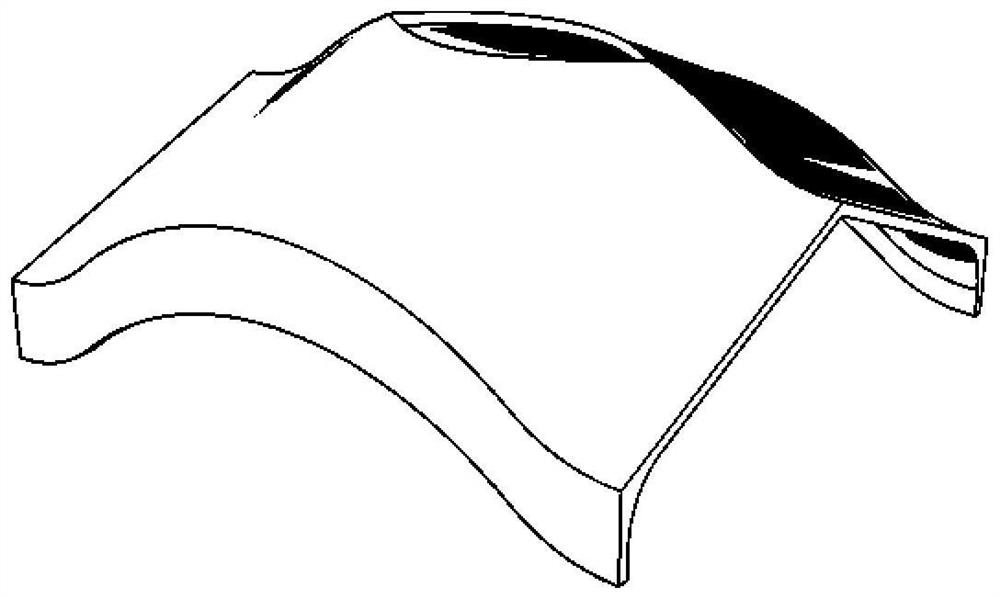

[0086] Please see attached figure 1 , Step 1: According to the design of the BIM software, construct the surface template, clean the surface of the surface template, so that there is no object blocking between the Faro 3D laser scanner and the surface template. The BIM model of the BIM software design is attached image 3 shown.

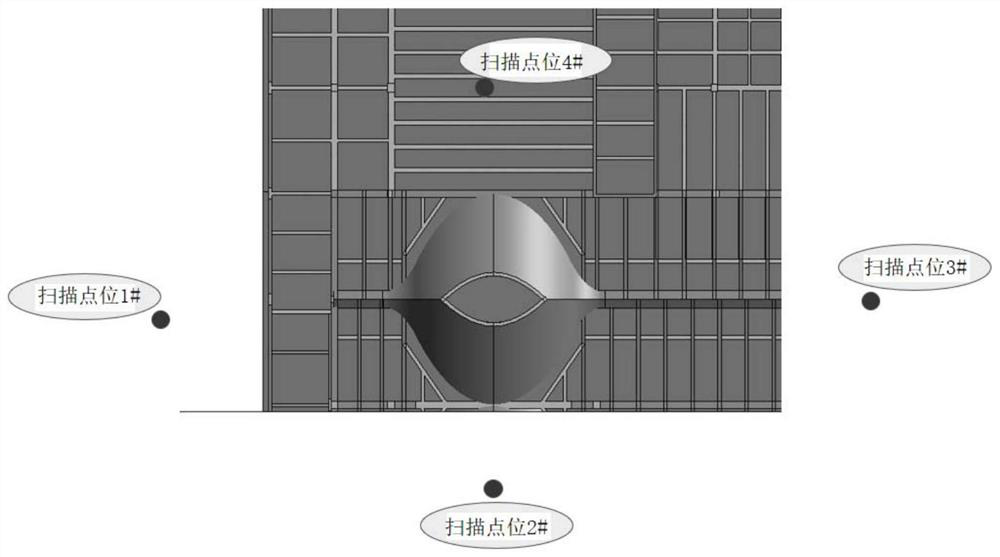

[0087] Please see attached figure 2 , According to the site situation, select a scanning point in the front, rear, left and right directions of the curved template, and the scanning point is about 10 meters away from the curved template, so that the scanning range of the 3D laser scanner in the four scanning points can be Covers the target area on the surface template for the desired measurement.

[0088] Adjust the parameters of the 3D laser scanner to outdoor operation parameters to reduce the influence of environmental factors on the scanning effect of the 3D laser scanner. The construction site is temporarily blocked to prevent the on-site c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com