Stainless steel welded joint intergranular corrosion test method

A welding joint and intergranular corrosion technology, which is applied in the fields of weather resistance/light resistance/corrosion resistance, instruments, design optimization/simulation, etc., can solve problems such as excessive manpower, shortened test cycle, and unfavorable test results, so as to reduce manpower consumption , shorten the test cycle, and ensure the effect of the test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

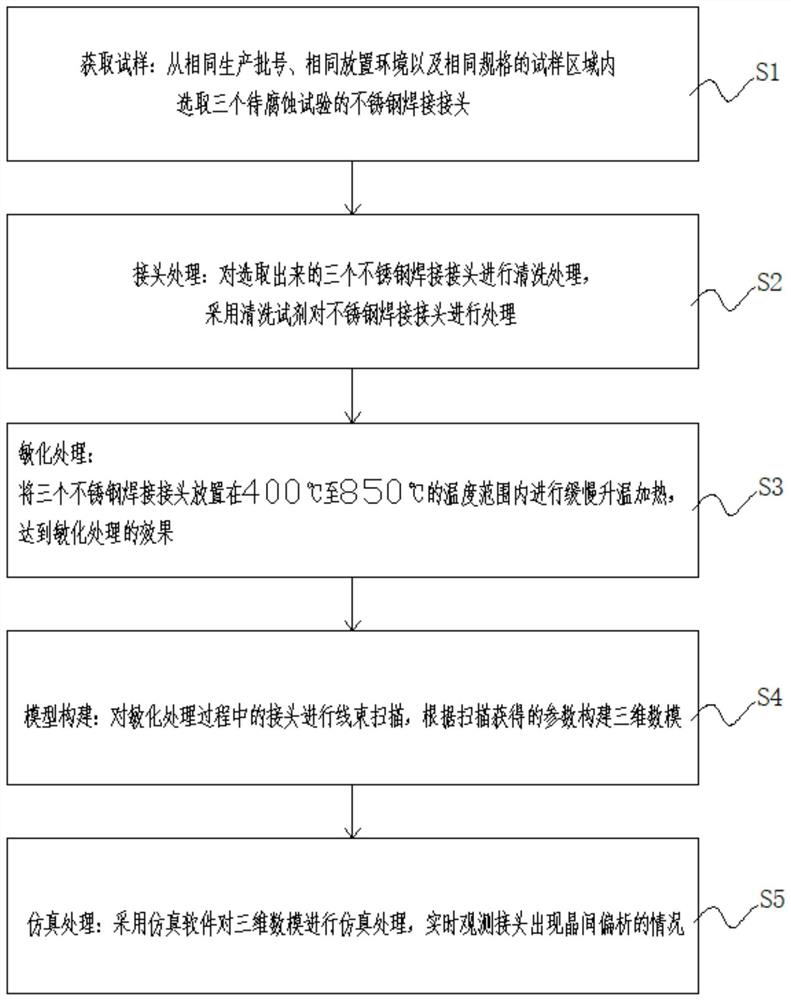

[0024] like figure 1 As shown, a method for testing intergranular corrosion of stainless steel welded joints includes the following steps:

[0025] S1. Obtaining samples: select three stainless steel welded joints to be tested for corrosion from the same production batch number, the same placement environment and the same specification of the sample area;

[0026] S2. Joint treatment: clean the three selected stainless steel welded joints, and use cleaning reagents to treat the stainless steel welded joints. The cleaning reagents used for cleaning the joints are acidic reagents, and hydrochloric acid is the best;

[0027] S3. Sensitization treatment: place the three stainless steel welded joints in the temperature range of 400°C to 850°C for slow heating to achieve the effect of sensitization treatment;

[0028] S4. Model construction: scan the wire beam for the joints in the sensitization process, and construct a three-dimensional digital model according to the parameters ob...

Embodiment 2

[0035] like figure 1 As shown, a method for testing intergranular corrosion of stainless steel welded joints includes the following steps:

[0036] S1. Obtaining samples: select three stainless steel welded joints to be tested for corrosion from the same production batch number, the same placement environment and the same specification of the sample area;

[0037] S2. Joint treatment: clean the three selected stainless steel welded joints, and use cleaning reagents to treat the stainless steel welded joints. The cleaning reagents used for cleaning the joints are acidic reagents, and hydrochloric acid is the best;

[0038] S3. Sensitization treatment: place the three stainless steel welded joints in the temperature range of 400°C to 850°C for slow heating to achieve the effect of sensitization treatment;

[0039] S4. Model construction: scan the wire beam for the joints in the sensitization process, and construct a three-dimensional digital model according to the parameters ob...

Embodiment 3

[0046] like figure 1 As shown, a method for testing intergranular corrosion of stainless steel welded joints includes the following steps:

[0047] S1. Obtaining samples: select three stainless steel welded joints to be tested for corrosion from the same production batch number, the same placement environment and the same specification of the sample area;

[0048] S2. Joint treatment: clean the three selected stainless steel welded joints, and use cleaning reagents to treat the stainless steel welded joints. The cleaning reagents used for cleaning the joints are acidic reagents, and hydrochloric acid is the best;

[0049] S3. Sensitization treatment: place the three stainless steel welded joints in the temperature range of 400°C to 850°C for slow heating and heating to achieve the effect of sensitization treatment;

[0050] S4. Model construction: scan the wire beam for the joints in the sensitization process, and construct a three-dimensional digital model according to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com