Preparation method of metal/metal oxide lithium-sulfur battery positive electrode skeleton structure

A skeleton structure, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, structural parts, etc., can solve problems such as unsatisfactory conductivity, limited active sites, and performance that have not reached commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

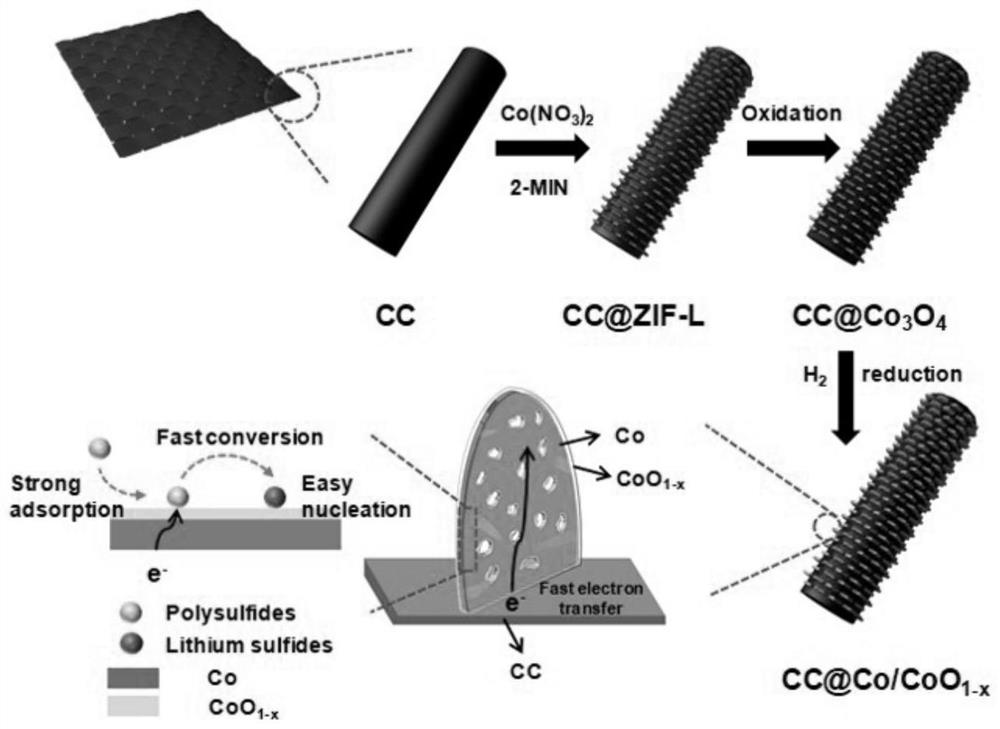

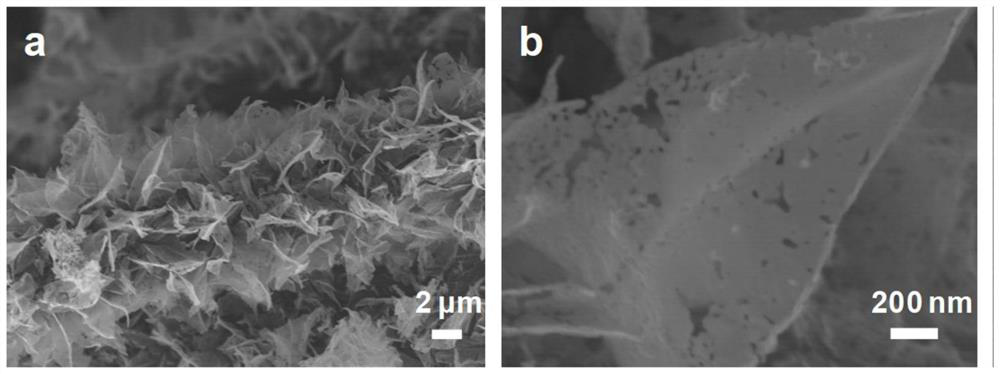

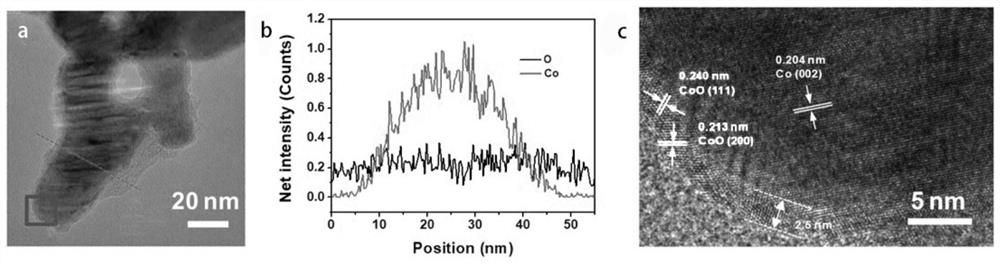

[0032] A two-dimensional porous core-shell structure combined with oxygen vacancies in CC@Co / CoO 1-x The cathode skeleton structure of the nanosheet array lithium-sulfur battery is characterized by, such as figure 2 a, CC@Co / CoO 1-x Has a uniform nanosheet array structure, which is seamlessly connected by many irregular nanosheets originating from H 2 reduced Co 3 O 4 The Co atoms obtained from the nanoparticles are polymerized, and this structure is conducive to accelerating charge transfer and enhancing structural stability. like figure 2 b, the Co / CoO 1-x Nanosheets are porous structures, and the nanopores originate from Co 3 O 4 There is a huge volume shrinkage (about 49%) during the conversion of the particles to Co. like image 3 a, STEM and line scan results show that Co / CoO 1-x In nanosheets, Co is mainly distributed in the inner core of nanosheets; such as image 3 b, HRTEM results confirm the Co / CoO 1-x The nanosheets have a core-shell structure, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com