Automatic switching step-down circuit

A step-down circuit and automatic switching technology, applied in the direction of electrical components, adjusting electrical variables, high-efficiency power electronic conversion, etc., can solve the problems of reduced equipment life, loss of electronic components, equipment heating, etc., to reduce load damage and improve use efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

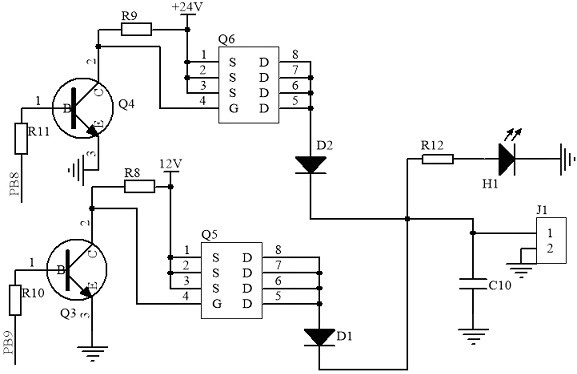

[0016] The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings.

[0017] refer to figure 1 , an automatic switching step-down circuit, in which the two input terminals PB8 and PB9 are respectively connected to transistors Q4 (B pole) and Q3 (B pole) through resistors, and transistors Q4 and Q3 are respectively connected to MOS transistors Q6 and Q5, MOS transistor Q6 and Q5 are respectively connected to socket J1 through diodes D2 and D1, and at the same time lead out wiring to be connected to light-emitting diode H1.

[0018] Specifically, resistors are respectively connected between the input terminals PB8 and PB9 and the transistors Q4 and Q3 to perform current limiting. Resistors are connected in series between the transistors Q4 and Q3 and the MOS transistors Q6 and Q5 respectively, and the resistance value of the series resistor is greater than 2K. The C-pole leads of the transistors Q4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com