5G rapid response intelligent welding robot

A welding robot and quick-response technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inhaling harmful gas, harmful to human body, low intelligence, etc., to improve the use effect and prevent dust Entering and avoiding the effect of walking deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

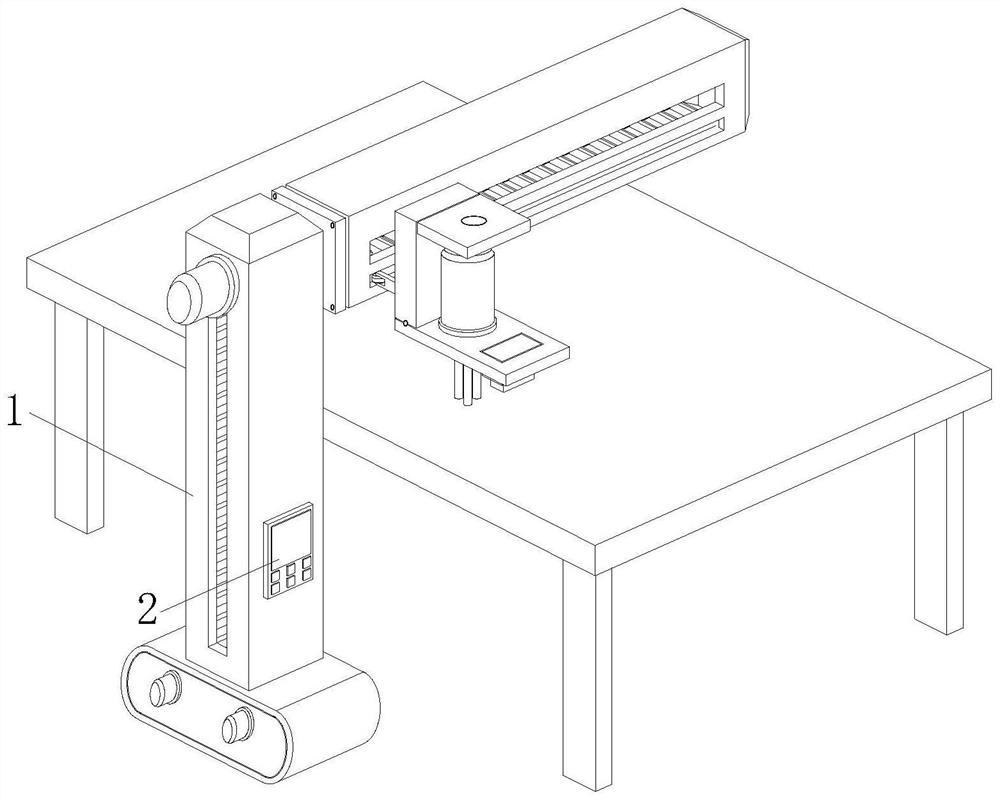

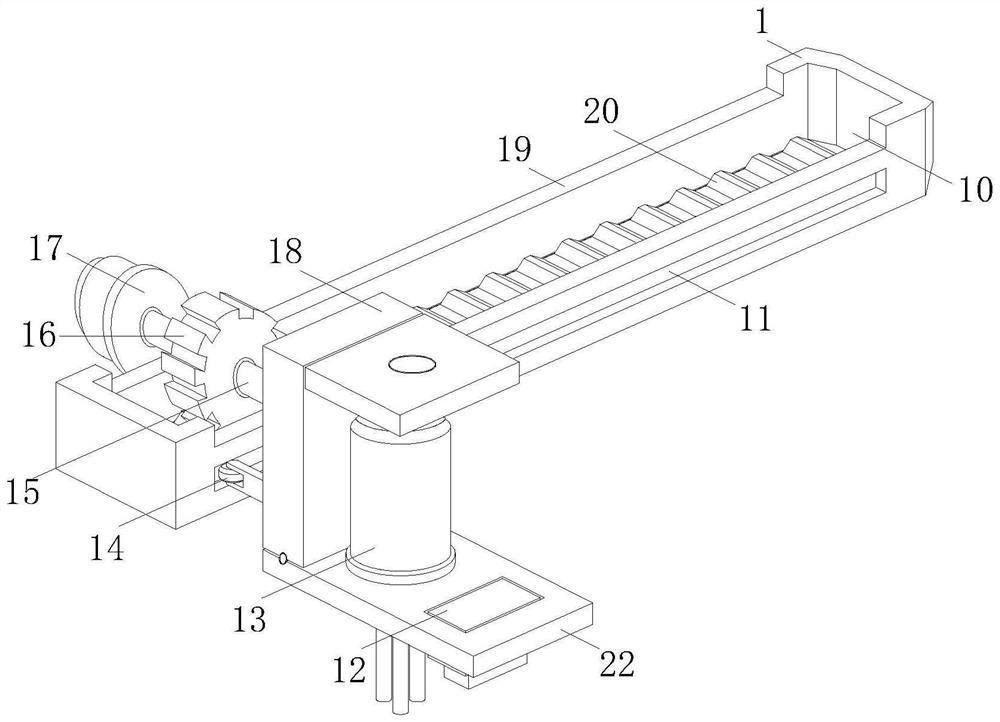

[0027] see Figure 1-6 , the present invention provides the following technical solutions: a 5G quick-response intelligent welding robot, comprising a walking mechanism that moves along the Z-axis direction, the top of the walking mechanism is equipped with a first welding position adjustment mechanism that moves along the Y-axis direction, and the first welding position The adjustment structure is equipped with a control mechanism. One side of the first welding position adjustment structure is equipped with a second welding position adjustment mechanism that moves along the X-axis direction. The second welding position adjustment mechanism is equipped with a welding mechanism. The control mechanism is controlled by 5G wireless communication. The traveling mechanism, the first welding position adjustment mechanism, the second welding position adjustment mechanism and the welding mechanism act.

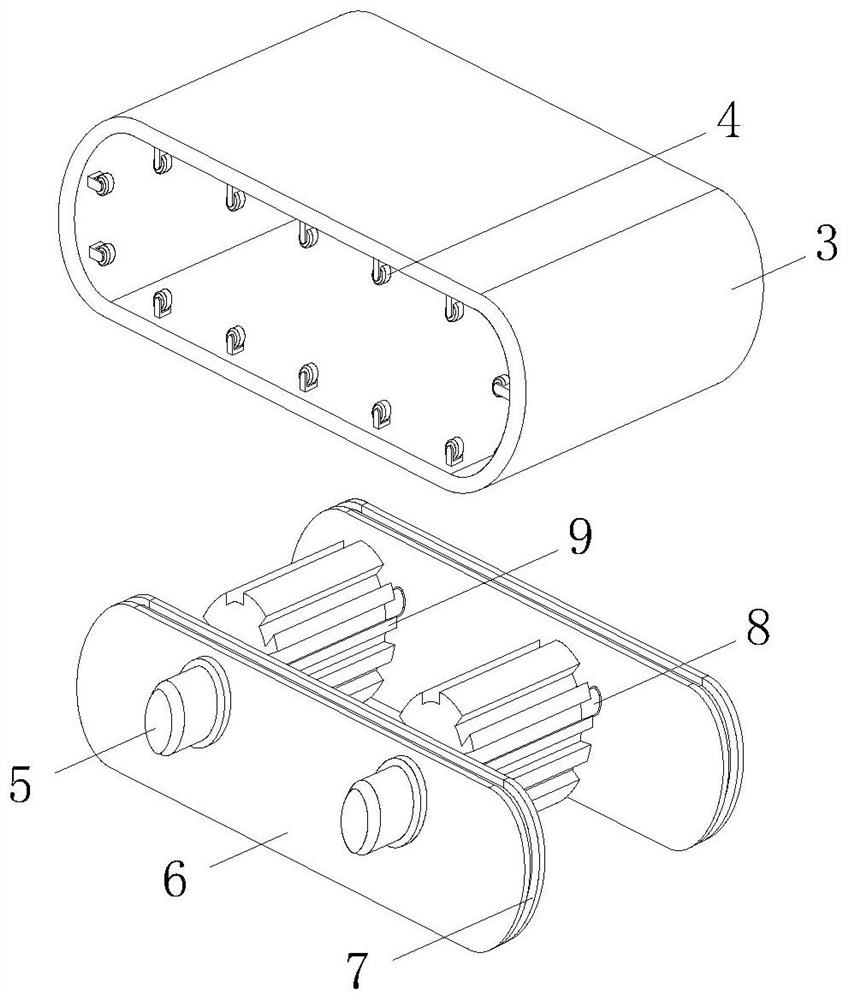

[0028] Specifically, the traveling mechanism includes a traveling crawler 3 that w...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is:

[0043] Specifically, the edge side of the dustproof plate 6 is provided with a first traveling groove 7 , and the edge side of the traveling track 3 is connected with a plurality of first traveling wheels 4 at equal intervals corresponding to the positions of the two first traveling grooves 7 .

[0044] Specifically, the side of the adjustment frame 1 of the first welding position adjustment mechanism close to the adjustment frame 1 of the second welding position adjustment mechanism and the side of the adjustment frame 1 of the second welding position adjustment mechanism close to the welding frame 18 are provided with second The traveling groove 11 , the adjusting frame 1 of the second welding position adjustment mechanism, and the welding frame 18 are symmetrically connected with two second traveling wheels 14 corresponding to the positions of the second traveling groove 11 , and the second traveling wheels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com