Integrated door pocket processing production line

A production line and door cover technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of occupying a large space, troublesome feeding process, complicated equipment, etc. The effect of simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

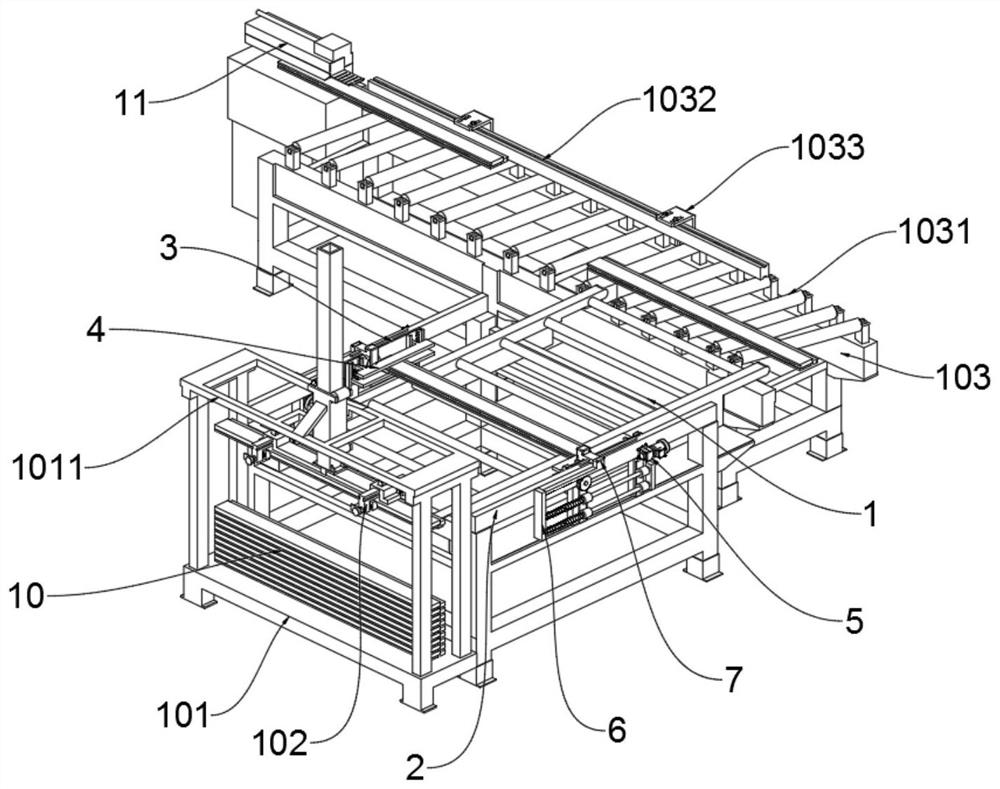

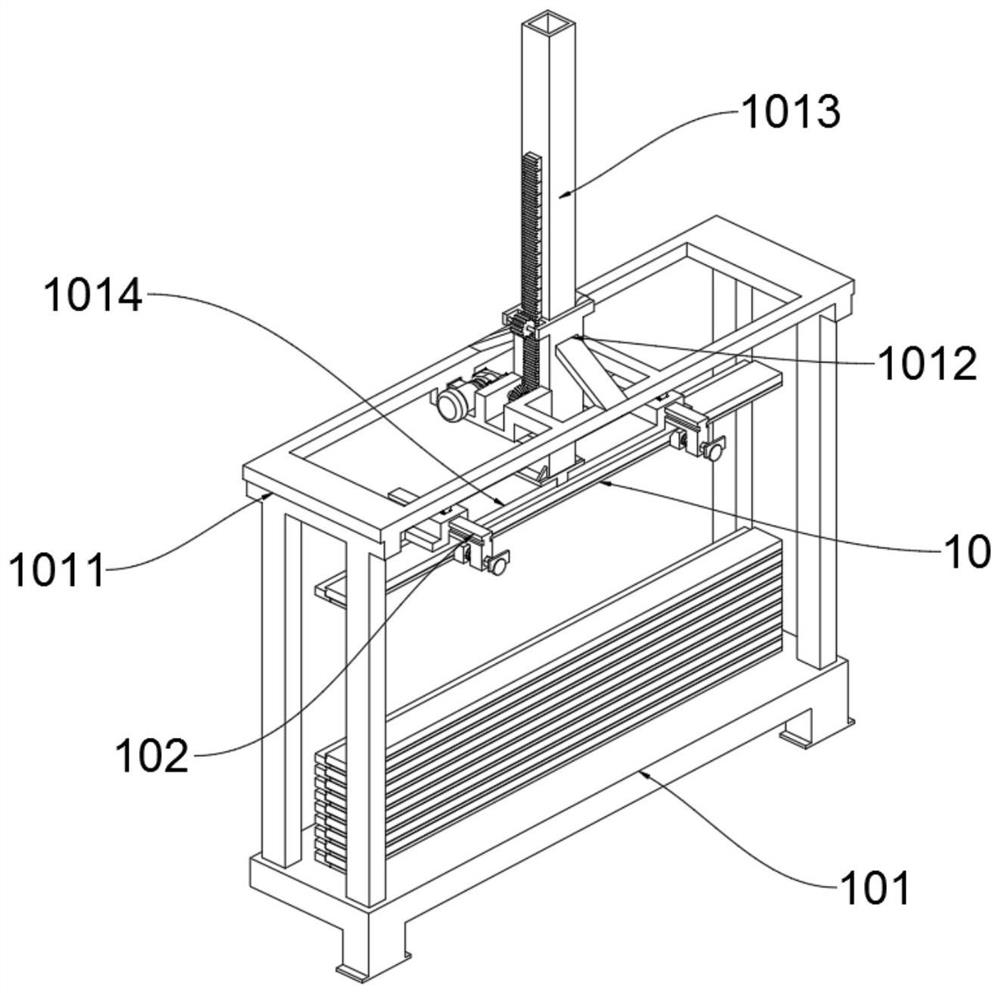

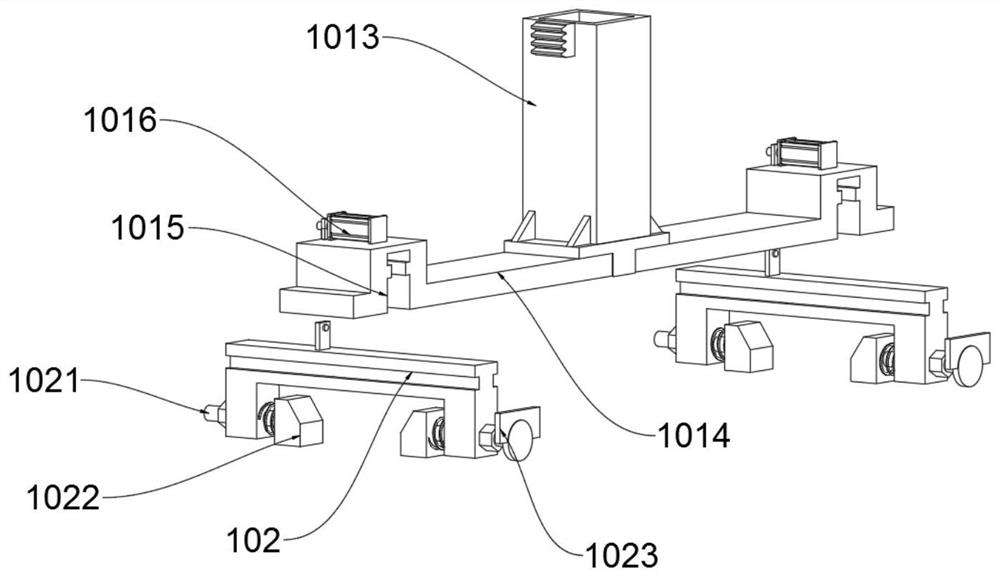

[0042] Example: please refer to Figure 1 to Figure 12 :

[0043] The present invention proposes an integrated door cover processing production line, comprising: a first transfer table 1 , a placing rack 101 is provided at the front of the first transfer table 1 ; a second transfer table 103 is provided at the rear of the first transfer table 1 , and the left side of the second transfer table 103 is provided with an edge wrapping machine 11; the left and right sides of the first transfer table 1 are provided with mounting racks 2, and the two mounting racks 2 are distributed in a symmetrical manner; the bottom of the mounting rack 2 is provided with two fixed positions The fixing frame 201 is fixedly connected with the first transmission table 1. The fixing frame 201 is provided with two limiting sleeves 204, and the two limiting sleeves 204 are distributed in a parallel manner up and down. The fixing frame 201 is provided with The mounting cavity 202, the top of the mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com