Frostless air source cascade heat pump steam generator and operation method thereof

A technology of steam generator and evaporator, which is applied in the field of waste heat recovery, which can solve the problems that the unit cannot work normally, it is difficult to apply the heat pump system, and the heat supply of the unit is reduced, so as to overcome low energy efficiency and intermittent heating operation, and improve area utilization rate and heat transfer efficiency, the effect of reducing carbon dioxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more clearly understood, the technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

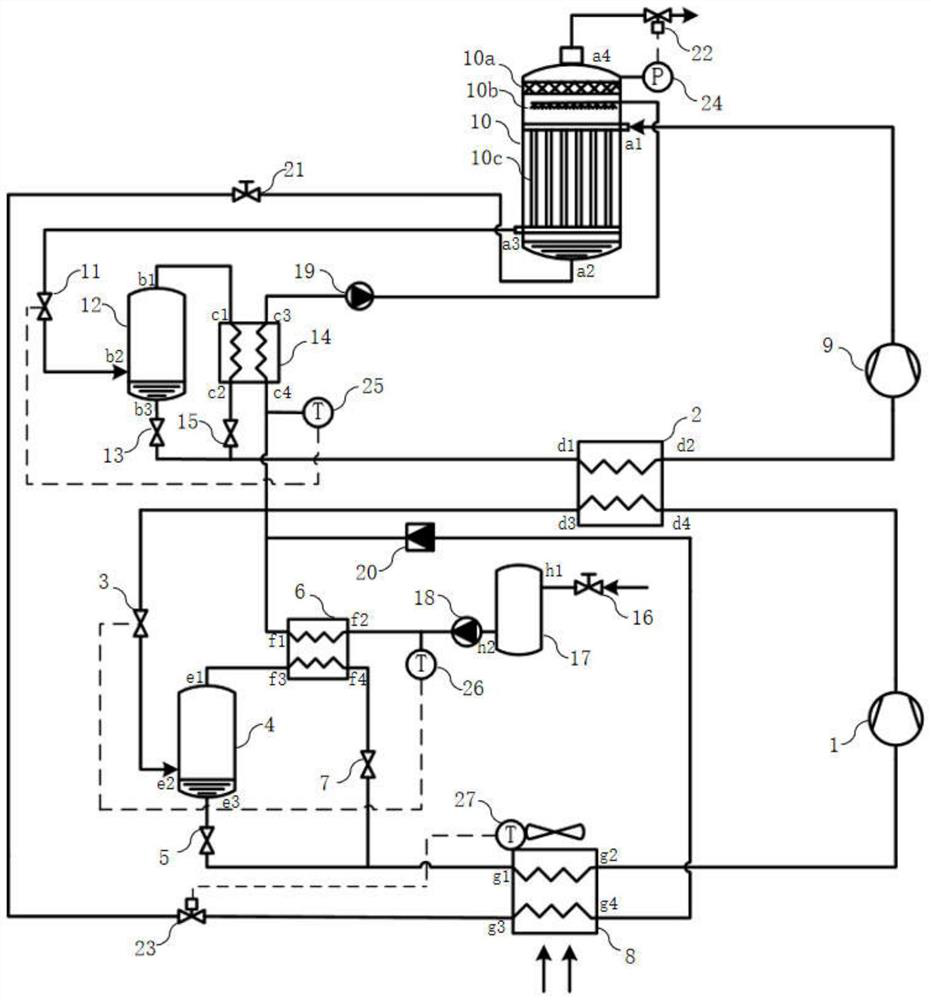

[0027] like figure 1 Shown: it is a frost-free air source cascade heat pump steam generator of the present invention, which includes a low temperature level circulation system, a high temperature level circulation system and a water system.

[0028] The low temperature stage circulation system includes: a first compressor 1, an evaporative condenser 2, a first throttle valve 3, a first gas-liquid separator 4, a second throttle valve 5, a first preheater 6, a third Throttle valve 7 and air source evaporator 8, the outlet of the first compressor 1 is connected to the lower inlet d4 of the evaporative condenser 2, and the lower outlet d3 of the evaporative condenser 2 is connected to the first air through the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com