Method and device for manufacturing surface microstructure of high-rate battery pole piece

A technology for battery pole pieces and manufacturing methods, which is applied to battery electrodes, electrode manufacturing, structural parts, etc., can solve the problems of reducing lithium battery volume capacity, increasing cost and efficiency, and increasing thickness, etc., to achieve rapid de-embedding and embedding processes, Enhanced charging and discharging performance, excellent motion path effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Due to the poor use effect of the existing lithium-ion battery structure and the structure of the battery pole piece, which cannot meet our needs, we designed a high-rate battery pole piece surface microarray based on the defects of the existing technology. The structure manufacturing method and device have the advantages of low cost, large volume of the lithium battery and good use effect.

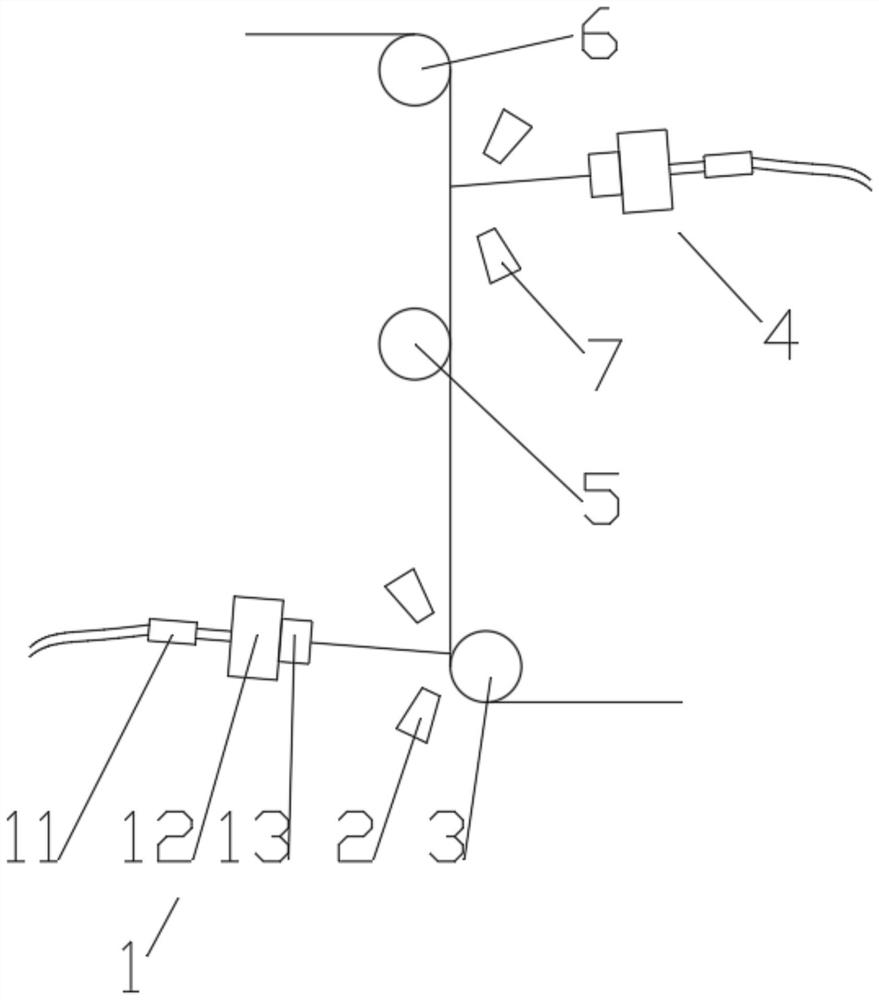

[0022] In order to facilitate those skilled in the art to understand the technical solution more clearly, the following will be combined with the appendix figure 1 Describe the technical scheme of the present invention in detail:

[0023] The technical solution of the present invention to achieve the above object is, a method for fabricating the surface microstructure of a high-rate battery pole piece, comprising the following working steps:

[0024] Step 1: The metal foil is coated with battery slurry, and the battery pole piece is obtained after drying and rolling;

[0025] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com