Non-acid system liquid-phase synthesized C/metal solid solution/Ni<2+>, Cu<2+>-doped ZrF<4> positive electrode and preparation method

A liquid phase synthesis and solid solution technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of charge and discharge capacity, charge and discharge capacity retention of discharge potential, complex mechanism of action, harsh process conditions, etc., and achieve excellent Electrochemical properties, reduction of kinetic hindrance, and effects of avoiding side reaction products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

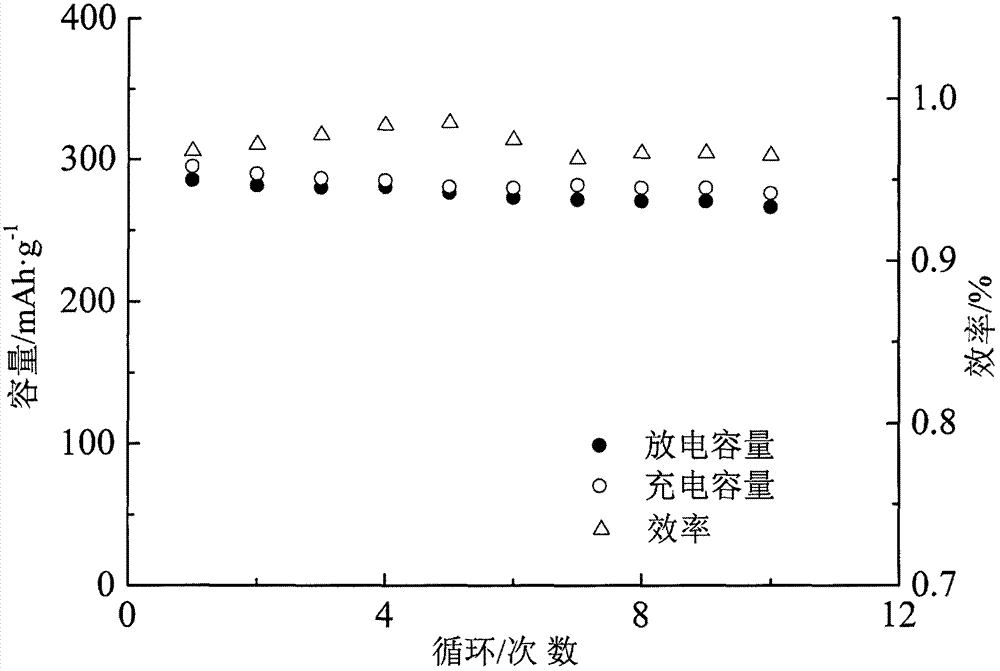

Image

Examples

Embodiment 1

[0013]Embodiment 1: be 1:4 zirconium nitrate pentahydrate and ammonium fluoride that the total mass is 1Kg with the amount of substance, the amount of substance is the copper sulfate pentahydrate of the amount of zirconium nitrate pentahydrate substance 0.5%, the amount of substance is The amount of zirconium nitrate pentahydrate 0.5% nickel nitrate hexahydrate is put into reactor, and this reactor is the cylindrical container of stainless steel material, and the ratio of the height of container and diameter is 2: 1, and the volume of container and nitric acid pentahydrate The ratio of zirconium to the sum of the mass of ammonium fluoride is 2L / Kg. Five circular fluid inlets are arranged on the top of the container, and their centers are respectively distributed at the center of the circular top of the container and the midpoints of four radii that form an angle of 90° with each other, and its diameter is 18% of the container diameter. Vibrate the reactor up and down, the ampl...

Embodiment 2

[0014] Embodiment 2: the zirconium nitrate pentahydrate and ammonium fluoride, the amount of substance being 2% copper sulfate pentahydrate of the amount of zirconium nitrate pentahydrate substance, the amount of substance being that 1: 4 total mass is 2Kg zirconium nitrate pentahydrate with the amount of substance is The amount of zirconium nitrate pentahydrate 2% nickel nitrate hexahydrate is put into reactor, and this reactor is the cylindrical container of stainless steel material, and the ratio of the height of container and diameter is 2.2: 1, and the volume of container and nitric acid pentahydrate The ratio of zirconium to the sum of the mass of ammonium fluoride is 3L / Kg. 5 circular fluid inlets are arranged on the top of the container, and their centers are respectively distributed at the center of the circular top of the container and the midpoints of four radii that form an angle of 90° with each other, and its diameter is 19% of the container diameter. Vibrate thi...

Embodiment 3

[0015] Embodiment 3: be that 1:4 total mass is zirconium nitrate pentahydrate and ammonium fluoride of 3Kg with the amount of substance, the amount of substance is the copper sulfate pentahydrate of the amount of zirconium nitrate pentahydrate substance 3%, the amount of substance is The amount of zirconium nitrate pentahydrate 3% nickel nitrate hexahydrate is put into reactor, and this reactor is the cylindrical container of stainless steel material, and the ratio of the height of container and diameter is 2.5: 1, and the volume of container and nitric acid pentahydrate The ratio of zirconium to the sum of the mass of ammonium fluoride is 5L / Kg. 5 circular fluid inlets are arranged on the top of the container, and their centers are respectively distributed at the center of the circular top of the container and the midpoints of four radii that form an angle of 90° with each other, and its diameter is 20% of the container diameter. Vibrate this reactor up and down, the amplitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com