Continuous conducive in-situ C/metal solid solution/Ce<4+>-doped CuF<2> positive electrode and preparation method

A solid solution, metal technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex mechanism, unpredictable effects, high polarization voltage, etc., to reduce kinetic obstacles, avoid side reaction products, and improve electrons. The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

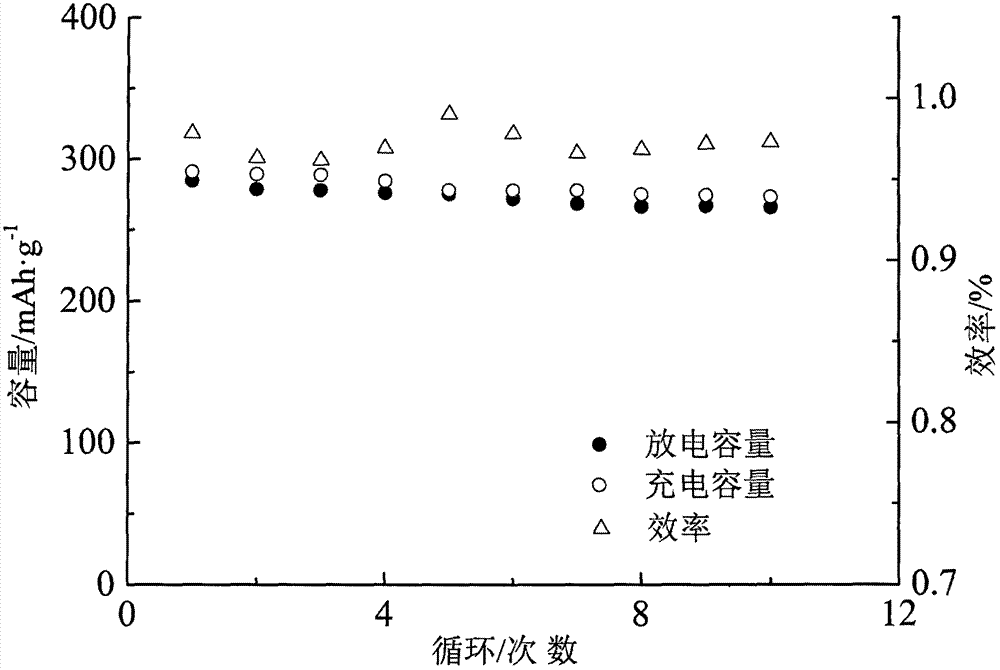

Embodiment 1

[0013]Example 1: The preparation composition is 5wt% copper nitrate, 0.1wt% cerium ammonium nitrate, 6wt% acrylamide, 1wt% N, N'-methylenebisacrylamide starting aqueous solution, using polytetrafluoroethylene stirring paddle to Stir at 900 rpm for 5 minutes. The initial aqueous solution was raised to 75°C at a rate of 5°C / min and maintained at this temperature until the initial aqueous solution became a jelly-like gel. Dry the formed gel in a low-temperature and high-vacuum environment. The drying process adopts the finished freeze dryer on the market. Put the gel into the sample tray of the freeze dryer and start the refrigerator. Reduce to minus 45°C, turn on the vacuum pump to increase the vacuum degree, wait until the gas pressure in the system drops below 25Pa, turn on the partition temperature control to start dehydration and drying, other operating parameters adopt the machine preset value, after the air pressure in the system is stabilized and the drying is completed, ...

Embodiment 2

[0014] Embodiment 2: The preparation composition is the initial aqueous solution of 15wt% copper nitrate, 0.5wt% cerium ammonium nitrate, 12wt% acrylamide, 2wt% N, N'-methylenebisacrylamide, using polytetrafluoroethylene stirring paddle to Stir at 1200 rpm for 15 minutes. The initial aqueous solution was raised to 85°C at a rate of 10°C / min and maintained at this temperature until the initial aqueous solution became a jelly-like gel. Dry the formed gel in a low-temperature and high-vacuum environment. The drying process adopts the finished freeze dryer on the market. Put the gel into the sample tray of the freeze dryer and start the refrigerator. Reduce to minus 50°C, turn on the vacuum pump to increase the vacuum degree, wait for the gas pressure in the system to drop below 32Pa, turn on the temperature control of the clapboard to start dehydration and drying, other operating parameters adopt the machine preset value, after the air pressure in the system is stabilized and the...

Embodiment 3

[0015] Example 3: Preparation of an initial aqueous solution consisting of 7wt% copper nitrate, 0.3wt% cerium ammonium nitrate, 9wt% acrylamide, and 1.5wt% N, N'-methylenebisacrylamide, using a polytetrafluoroethylene stirring paddle Stir at 1150 rpm for 10 minutes. The initial aqueous solution was raised to 80°C at a rate of 7°C / min and maintained at this temperature until the initial aqueous solution became a jelly-like gel. Dry the formed gel in a low-temperature and high-vacuum environment. The drying process adopts the finished freeze dryer on the market. Put the gel into the sample tray of the freeze dryer and start the refrigerator. Reduce to minus 48°C, turn on the vacuum pump to increase the vacuum degree, wait for the gas pressure in the system to drop below 30Pa, turn on the temperature control of the clapboard to start dehydration and drying, other operating parameters adopt the machine preset value, and after the air pressure in the system is stabilized and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com