Direct insertion type sealed circular electric connector

An electrical connector and in-line technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the production work that cannot be realized quickly, the production work of stamping processing is inconvenient, and the work of mechanical processing is unfavorable and other problems, to achieve the effect of separating transmission work, efficient production work, and realizing split production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

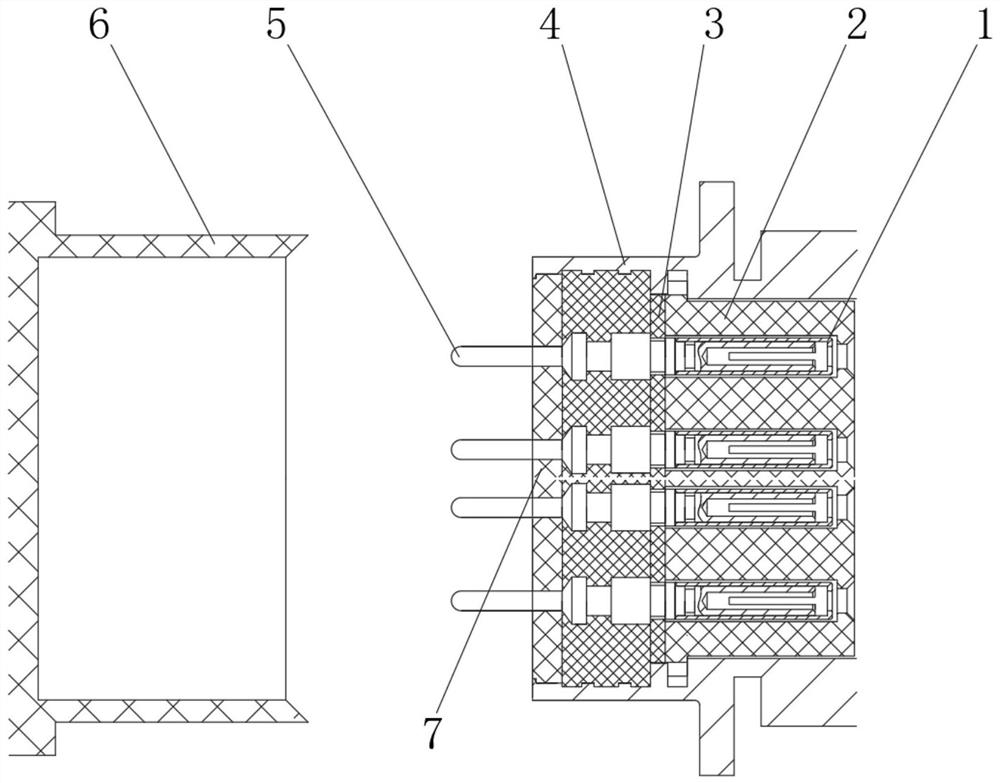

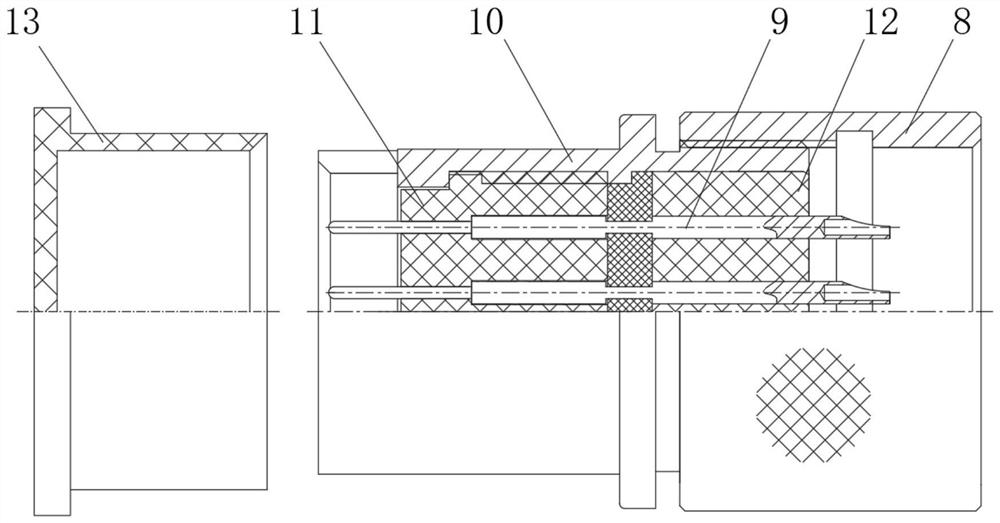

[0052] See Figure 1 、 Figure 2 , an embodiment of the present invention provided: an in-line, sealed circular electrical connector, including plugs and sockets, by connection combination, to facilitate the overall installation combination;

[0053] The socket comprises a sheath 1, an insulator under the socket 2, a rubber pad 3, a seat housing 4, a jack 5, a first protective cap 6 and an insulator on the socket 7;

[0054] The side end position of the sheath 1 is fixedly connected to the insulator under the socket 2, the bottom end of the sheath 1 is fixed to the jack 5, the side end of the insulator 2 under the socket is fixed with the rubber pad 3, the side end of the rubber pad 3 is fixed to the insulator 7 on the socket, the rubber pad 3, the outer end of the insulator 7 on the socket is set with the seat shell 4, and the side end position of the jack 5 is provided with the first protective cap 6, which is convenient for forming and connecting work through the setting of the s...

Embodiment 2

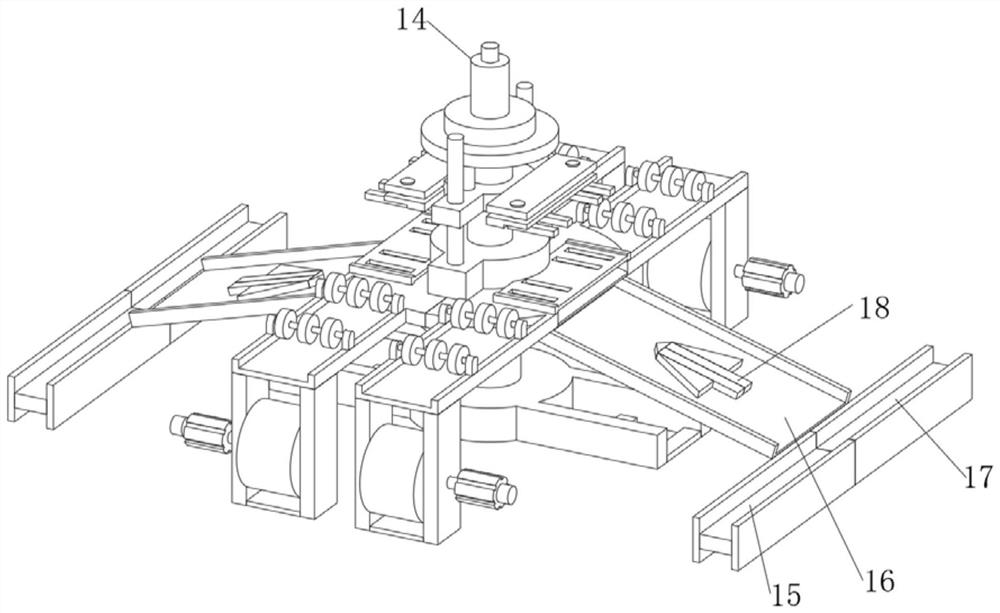

[0070] On the basis of Example 1, e.g., Figure 10 As shown, the side end position of the pressing production member 14 is fixedly connected to the supporting top plate frame 40, and the lower end of the supporting top plate frame 40 is fixedly connected to the protective incline frame 39.

[0071]In the present embodiment, by installing the protective bevel frame 39 and the support top plate frame 40, the protective bevel frame 39 is fixedly connected to the pressing production component 14 by supporting the top plate frame 40, to achieve the support installation work at the side end, and the setting of the protective slash 39 can realize the capping treatment of the upper part of the tilt frame 16, which is conducive to reducing the dust of the upper part, facilitating the dust-free production work, and at the same time facilitating the protection work to prevent the edge of the production material from falling.

[0072] Working principle: the user will press the production parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com