Building material integrated forming machine tool capable of achieving uniform coating

A building material and coating technology, which is applied to the device, coating, spraying device and other directions for applying liquid to the surface to achieve the effect of shortening the conversion time

Active Publication Date: 2022-06-10

新疆中城环宇建设工程有限公司

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to overcome the phenomenon of protrusions and depressions in the coating liquid, the catalytic liquid cannot be quickly integrated into the coating liquid, and a phase inversion reaction occurs, and the modified glass beads Can not be laid evenly, there will be the shortcomings of overlapping accumulation phenomenon, the invention provides a building material integral molding machine tool that can be evenly coated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

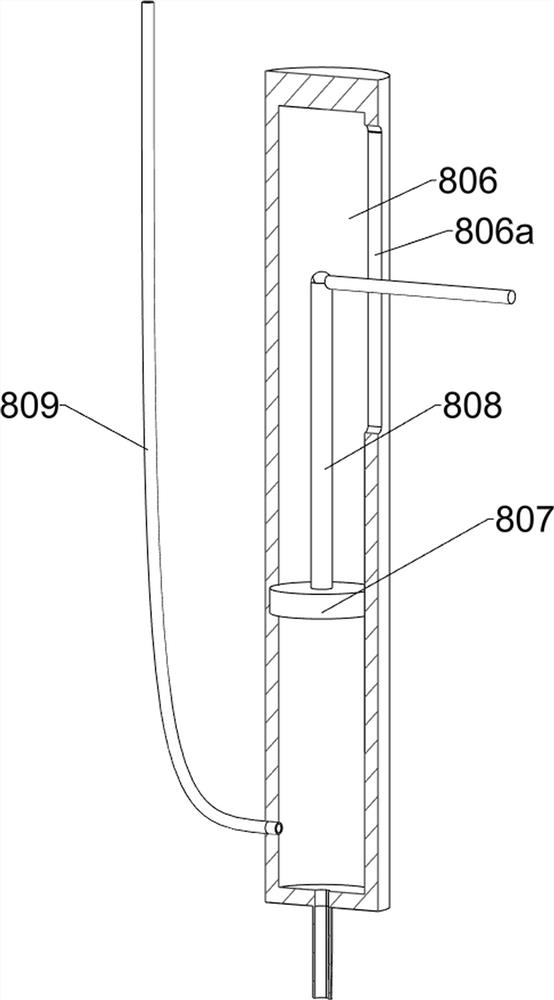

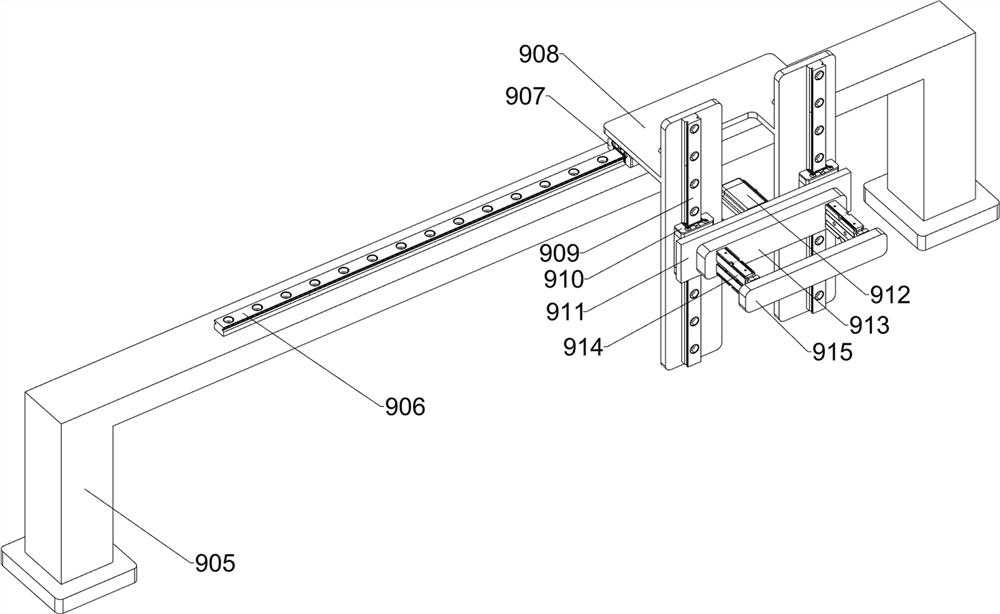

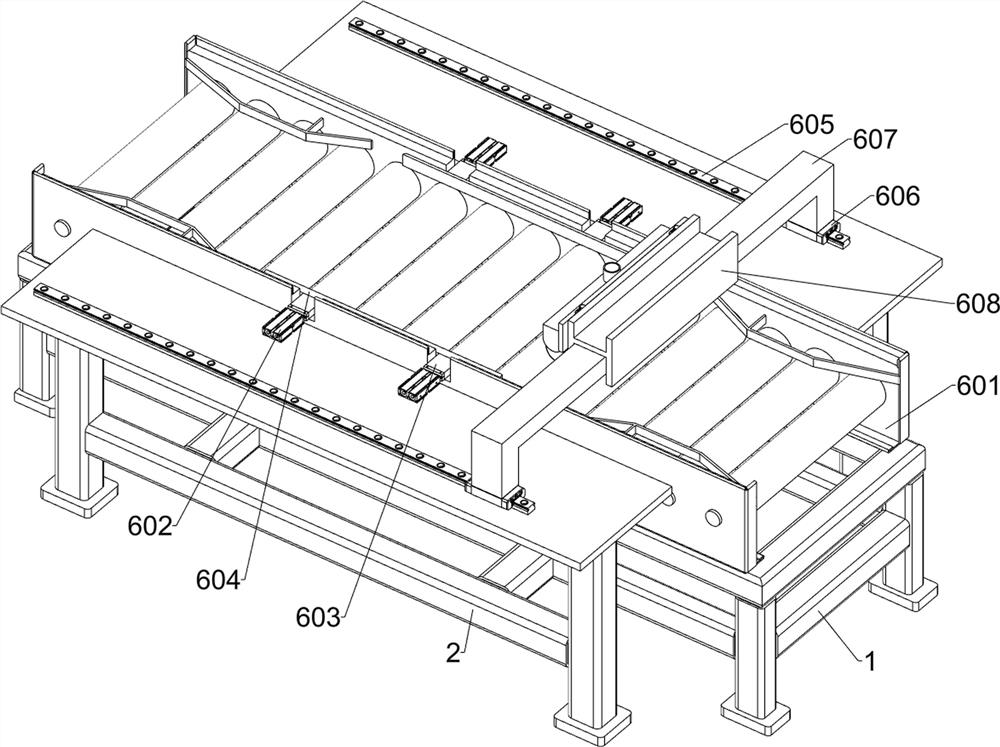

The invention relates to the field of building materials, in particular to a building material integrated forming machine tool capable of achieving uniform coating. The invention solves the technical problems that the coating liquid generates convex and concave phenomena, the catalytic liquid cannot be quickly fused into the coating liquid, the phase conversion reaction is generated, the modified glass beads cannot be uniformly laid, and the overlapping and stacking phenomena can be caused. According to the technical implementation scheme, the building material integrated forming machine tool capable of achieving uniform coating comprises a first bottom frame, a first supporting frame and the like; the front side face and the rear side face of the first bottom frame are each fixedly connected with a first supporting frame. The filling system is designed, raised coating liquid on the upper surface of the cement rock wool sandwich panel is sucked away, and the concave part of the upper surface of the cement rock wool sandwich panel is filled with the coating liquid, so that the coating liquid on the upper surface of the cement rock wool sandwich panel is uniformly distributed.

Description

technical field [0001] The invention relates to the field of building materials, in particular to a building material integral forming machine tool capable of uniform coating. Background technique [0002] The preparation method of the cement rock wool sandwich panel in the prior art is: apply the coating liquid evenly on one side of the cement rock wool sandwich panel, and then spray a catalytic liquid containing a phase transfer catalyst on it, and a phase inversion reaction occurs, After the reaction, the modified glass beads are evenly laid on the cement rock wool sandwich panel. Since the upper surface of the cement rock wool sandwich panel is not completely flat, the coated coating liquid will also have protrusions and depressions. , will affect the subsequent uniform contact with the catalytic liquid. The catalytic liquid is sprayed on the upper surface of the coating liquid of the cement rock wool sandwich panel. It is necessary to wait for the catalytic liquid to sl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B05B13/02B05B15/00B05C5/02B05B13/04B05C19/04B05C19/06

CPCB05B13/0221B05B13/0278B05B15/00B05C5/02B05B13/041B05C19/04B05C19/06Y02A30/244

Inventor 雷永恒

Owner 新疆中城环宇建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com