Reusable hanging type rotary air inlet paint spraying pot

A technology of rotating air intake and air intake, which is applied in the direction of injection devices, valve devices, engine components, etc., to achieve the effects of strengthening connection stability, speeding up production, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

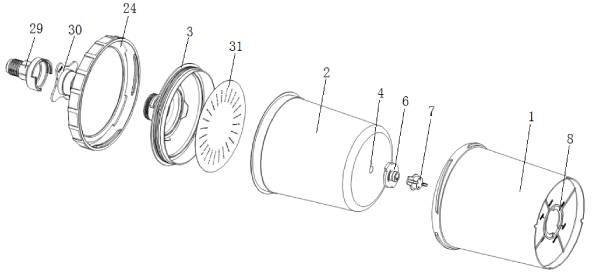

Image

Examples

Embodiment 1

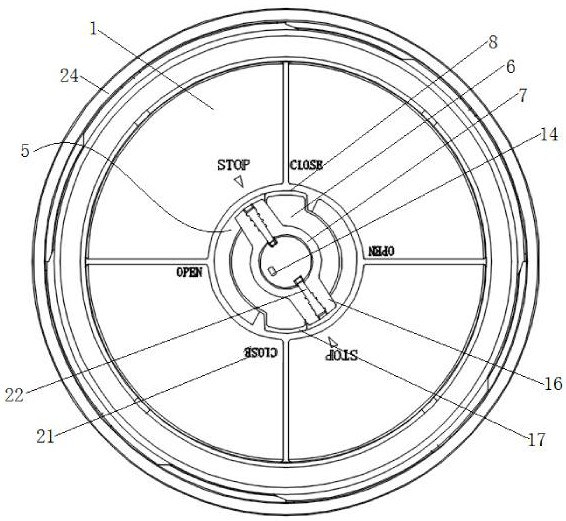

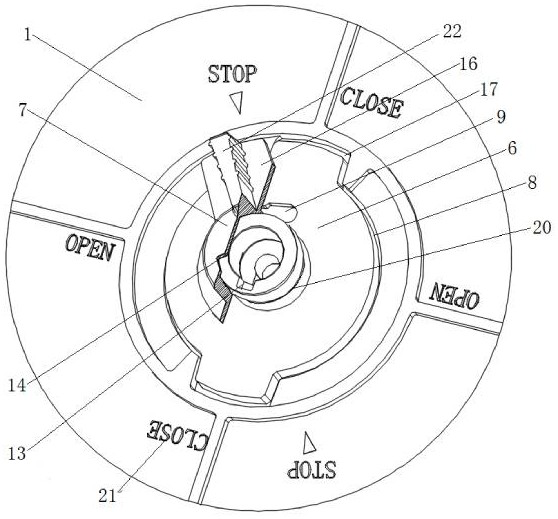

[0039] The valve cover 7 is provided with an anti-loosening groove 19, the center of the valve seat 6 is provided with an air intake pipe 23 communicating with the air hole 4, and the outer periphery of the air intake pipe 23 is provided with the anti-disengagement pipe 23. The snap ring 20 matched with the release groove 19, the valve seat 6 and the valve cover 7 are tightly and rotationally engaged.

[0040] The air intake groove 7 is provided with at least one group, and each group of the air intake groove 7 is two and arranged on the inner wall of the air intake card tube 23 from top to bottom in sequence, and one of the air intake grooves 7 is located at The top of the air intake clamping tube 23, the lower end of the valve cover 7 is provided with a sealing clamping column 27 that is sealed and rotatably connected in the intake clamping tube 23, and the sealing clamping column 27 is provided with the air intake groove. There are 7 sets of intake communication slots 28 co...

Embodiment 2

Two groups of the air intake grooves 7 are symmetrically formed on the inner wall of the air intake clamping tube 23 , and two intake communication grooves 28 are symmetrically formed on the sealing clamping post 27 .

[0051] Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0052] By setting two sets of air intake slots, the amount of air intake is increased to ensure that the inner liner does not deform or leak, so as to avoid serious deformation of the inner liner under negative pressure when a single set of air intake slots is in use, causing the bottom valve cover to hang on the outer pot body The large force at the bottom may cause the valve cover to detach.

[0053] The working principle of a reusable hooked rotary air-intake paint spray pot provided by the present invention is as follows: when in use, first rotate the limit post 10 to the sealing position 12 of the valve body, then pour the paint into the inner ...

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com