Concrete composite board

A technology for concrete and composite panels, which is used in instruments, fluid tightness testing, and machine/structural component testing to improve connection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

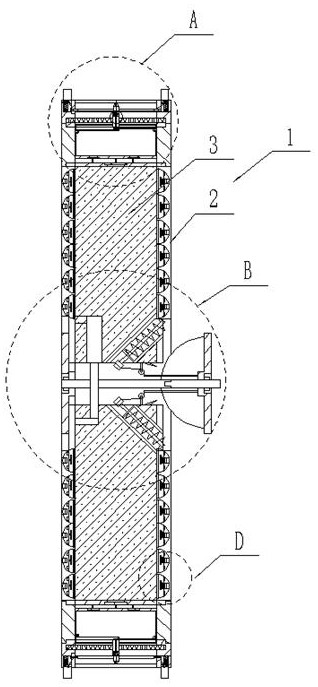

Image

Examples

Embodiment Construction

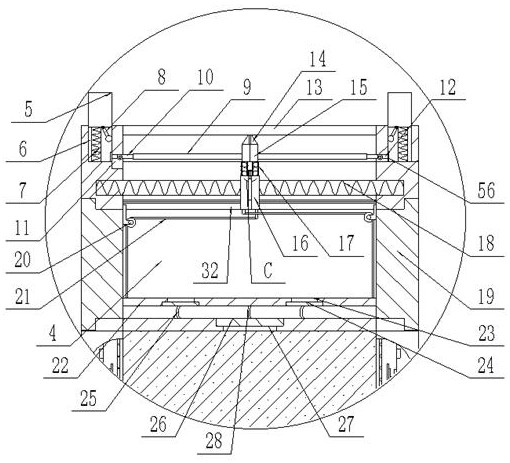

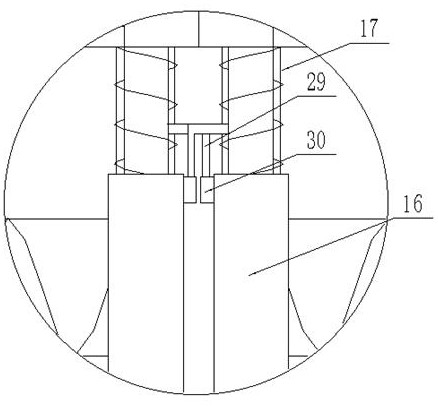

[0024]The bypass linkage assembly includes: a bypass channel 36, a spiral push piece 37, a winding column 38, a second linkage steel wire 39, a second fixed pulley 40, and a linkage ejector pin 45; the bypass channel 36 is opened between the connection frame 2 and the concrete Between the filling bodies 3, and the bypass channel 36 is at a position close to the support screw 42, the screw push piece 37 is rotated and inserted in the bypass channel 36, and the winding column 38 is connected to the bypass channel 36 by the rotating shaft to be close to the support At the port of the screw rod 42, the winding column 38 is coaxially connected with the spiral push piece 37, the second linkage steel wire 39 is wound and connected on the winding column 38, the linkage ejector rods 45 are fixedly connected to the closing cover 41 in pairs, and the second linkage The end of the steel wire 39 is connected to the end of the interlocking push rod 45; the second fixed pulley 40 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com