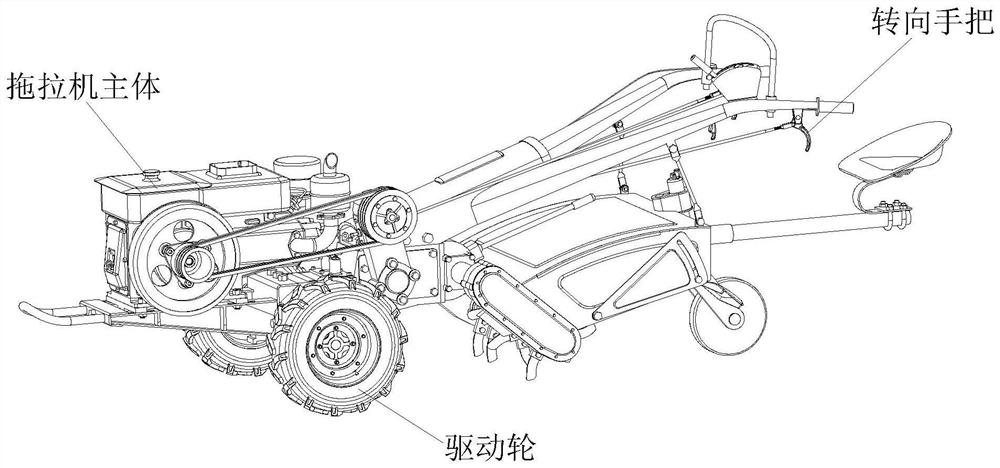

Quick-assembly type electric reversing device of agricultural tractor

An electric reversing and tractor technology, applied in electric steering mechanisms, guiding agricultural implements, mechanical steering gears, etc., can solve the problems of tooth breaking accident and wear of meshing teeth that transmit power, and achieve the effect of promoting meshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

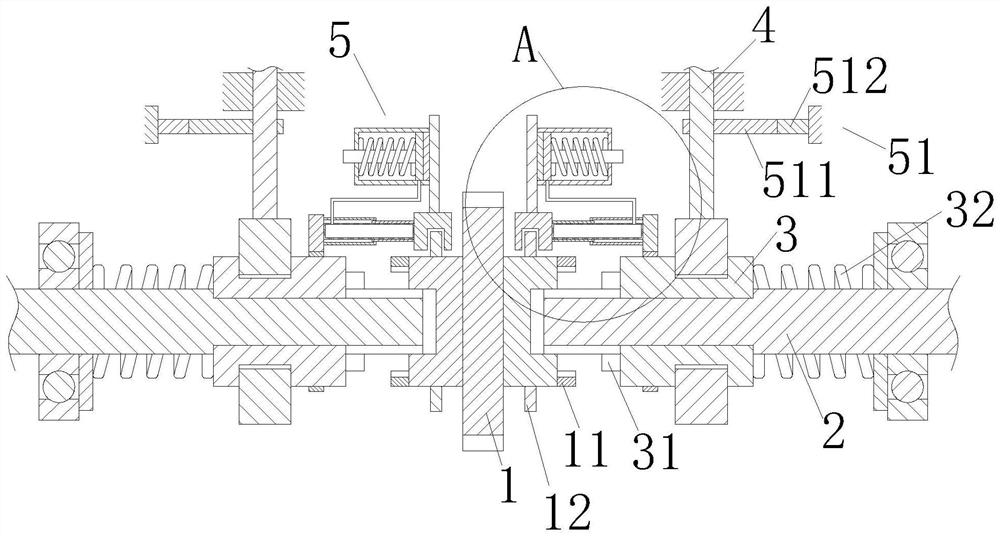

[0043] The quick-installed electric reversing device of an agricultural tractor according to the present invention includes a clutch, and the clutch is arranged in the tractor body;

[0044] The clutch includes:

[0045] The central transmission gear 1, the two ends of the central transmission gear 1 are fixedly installed with a No. 1 meshing tooth 11;

[0046] There are two rotating shafts 2, which are distributed at both ends of the central transmission gear 1 and are rotatably installed in the tractor body. One end of the rotating shaft 2 close to the central transmission gear 1 is movably connected with a steering block 3, so One end of the steering block 3 close to the central transmission gear 1 is fixedly installed with a No. 2 meshing tooth 31, and one end of the steering block 3 away from the central transmission gear 1 is connected to the tractor body through a No. 1 spring 32;

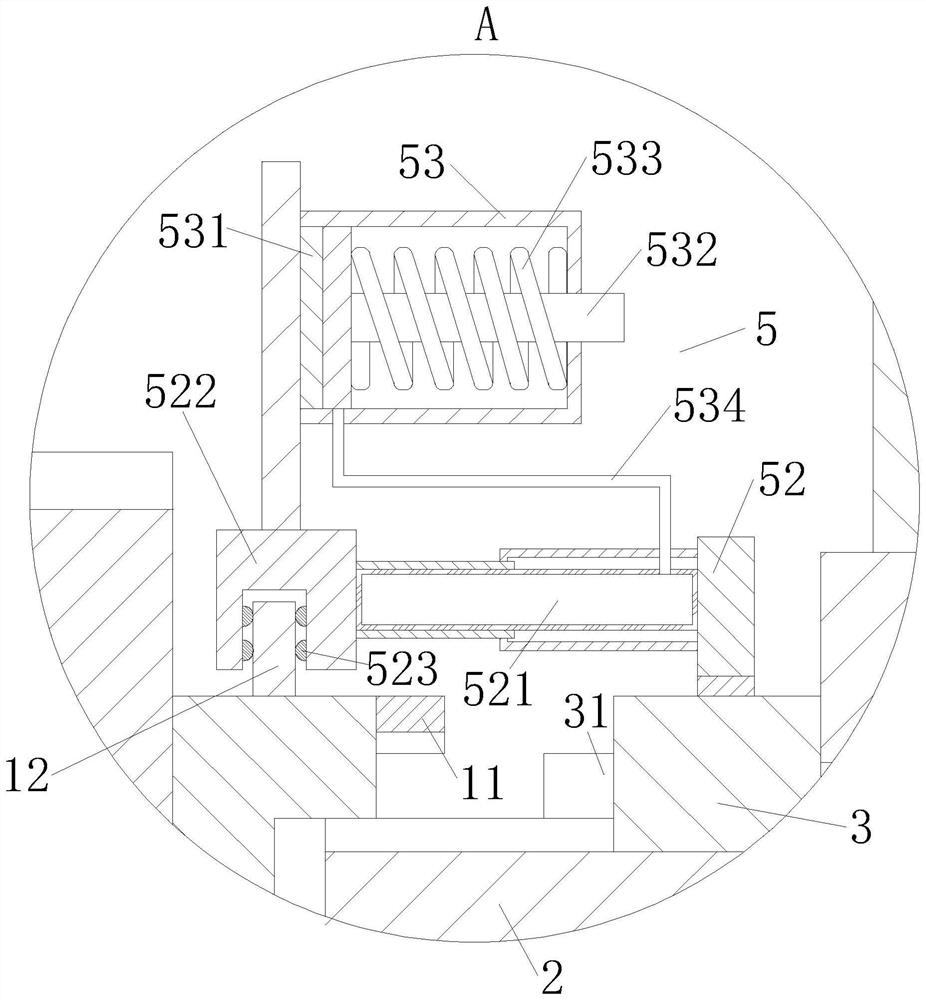

[0047] Steering fork 4, a steering fork 4 is rotatably installed in the tractor body, a...

Embodiment 2

[0069] An electric reversing device of a quick-installation type agricultural tractor, comprising a clutch, and the clutch is arranged in the tractor body;

[0070] The clutch includes:

[0071] The central transmission gear 1, the two ends of the central transmission gear 1 are fixedly installed with a No. 1 meshing tooth 11;

[0072] There are two rotating shafts 2, which are distributed at both ends of the central transmission gear 1 and are rotatably installed in the tractor body. One end of the rotating shaft 2 close to the central transmission gear 1 is movably connected with a steering block 3, so One end of the steering block 3 close to the central transmission gear 1 is fixedly installed with a No. 2 meshing tooth 31, and one end of the steering block 3 away from the central transmission gear 1 is connected to the tractor body through a No. 1 spring 32;

[0073] Steering fork 4, a steering fork 4 is rotatably installed in the tractor body, and the position near the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com