Tubular nanofiber material, negative pole piece and lithium metal battery

A nanofiber, tubular technology, applied in the field of lithium metal batteries, can solve the problems of high activity of lithium metal, affecting the application of lithium metal, reducing Coulomb efficiency, etc., to avoid side reactions, improve capacity performance and cycle stability, and inhibit branching. crystal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0108]本申请还涉及所述管状纳米纤维的制备方法,其包含以下步骤:

[0109](1)通过静电纺丝法将聚合物A溶液形成第一纳米纤维;

[0110](2)将第一纳米纤维静置24小时以上,随后升温干燥,优选真空下干燥,得到第二纳米纤维;

[0111](3)在氮气气氛下,将第二纳米纤维高温处理形成纳米碳纤维;

[0112](4)将步骤(2)或(3)中获得的纤维浸入聚合物B溶液,随后升温干燥,优选真空下干燥,获得管状纳米纤维材料。

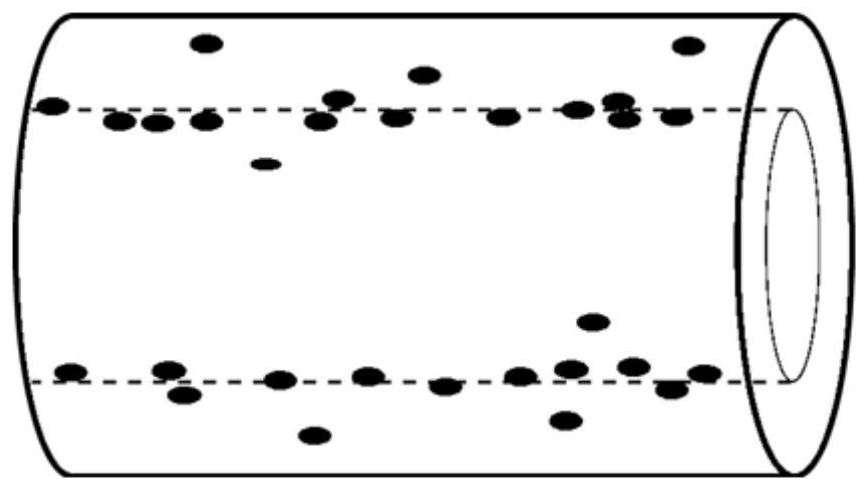

[0113]本申请中,步骤(4)中所得的管状纳米纤维材料即为可用于负极极片中的层状的三维骨架材料。

[0114]在上述方法的步骤(1)中,聚合物A选自导电性聚合物,例如聚吡咯烷酮、聚甲基丙烯酸甲酯、聚氧化乙烯、聚氧化丙烯、聚乙烯醇或聚苯乙烯,其数均分子量为100,000-2,000,000,其使用浓度为10-40wt%,所用溶剂选自酮类、酰胺类、醚类、酯类、卤代烃、芳烃,或其混合物,例如N,N-二甲基甲酰胺、乙醇和丙酮。

[0115]在上述方法的步骤(1)中,静电纺丝法的参数为:负压为-4kV,正压为12-20kV,进液速率为0.1-0.3mL / h,收集板与针头距离为15cm-20cm;收集滚筒转速1500-3000rpm。

[0116]在上述方法的步骤(1)中,聚合物A溶液还包括助剂冰醋酸(99质量%),其用于加速水解,其以纯冰醋酸计的用量为10-20重量%,基于聚合物A溶液的总重量计。

[0117]在上述方法的步骤(2)中,第一纳米纤维膜在常温下、相对湿度35%以上,优选35%-80%下,静置24-48小时;然后在真空下70-90℃下干燥10小时以上。

[0118]在上述方法的步骤(3)中,恒速,例如5-8℃ / 分钟,升温至800℃以上,干燥6小时以上。

[0119]在上述方法的步骤(4)中,聚合物B可以与聚合物A相同,也可以不同。本申请中,对于聚合物B的种类不做特别限定,选择的聚合物B只要可以满足形成管状纳米纤维的两端封闭结构即可,从而可达到改善电池的循环与安全性能的效果。本申请中,聚合物B的实例例如可选自聚偏氯乙烯、聚丙烯腈、聚氧化乙烯(PEO)、聚甲基丙烯酸甲酯(PMMA)和酚醛树脂,其数均分子量为100,000-2,000,000;其浓度为1-5wt%;所使用的溶剂选自酮类、醚类、酯类、卤代烃、芳烃,或其混合物,例如N-甲基吡咯烷酮、乙醇和丙酮。

[0...

Example Embodiment

[0179]实施例1

[0180]1.负极极片制备

[0181]管状纳米纤维材料(即三维骨架层)的制备:

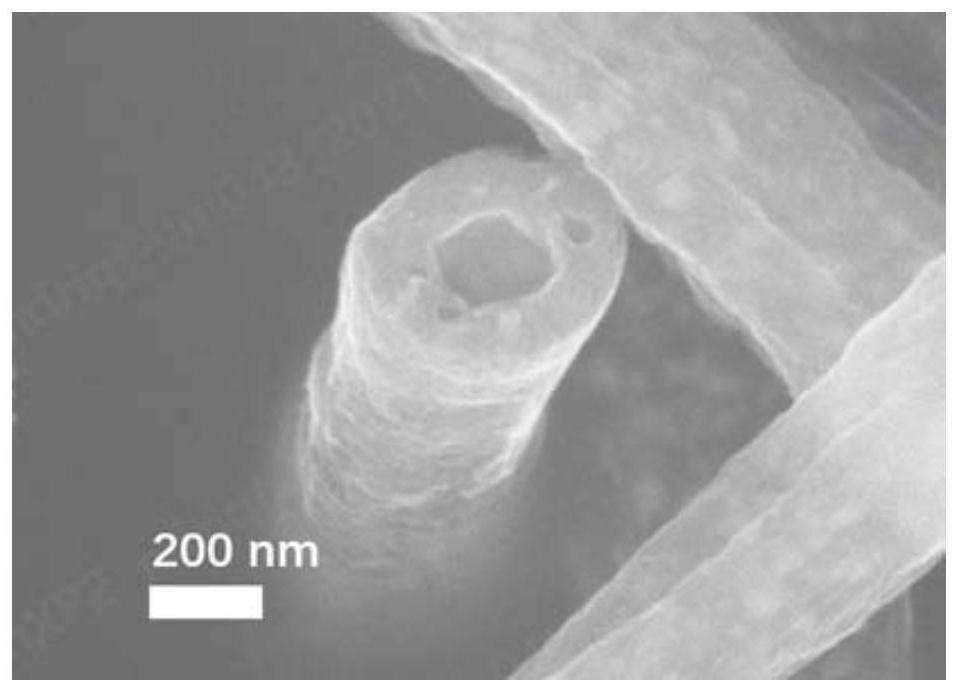

[0182]所含管状纳米纤维为中空的三维骨架层的制备:将2g聚乙烯吡咯烷酮(PVP)溶解于10g无水乙醇中搅拌4小时,然后加入2g冰醋酸(99重量%)、3.5g的硅酸四乙酯和1g的钛酸四丁酯,继续搅拌2小时,直至溶液形成均匀澄清的状态。将该溶液转移至针筒中进行静电纺丝,静电纺丝过程参数为:负压为-4kV,正压为18kV,进液速率为0.3mL / h,收集板与针头距离为20cm,收集滚筒转速为2000rpm,纺丝时间12小时。纺丝所得的材料在20℃和相对湿度50%下静置24小时,然后转移至真空干燥箱中在80℃下真空干燥12小时;接着在管式炉中在氮气气氛下,以5℃每分钟升温至800℃保持6小时,获得所含管状纳米纤维为中空的三维骨架层。

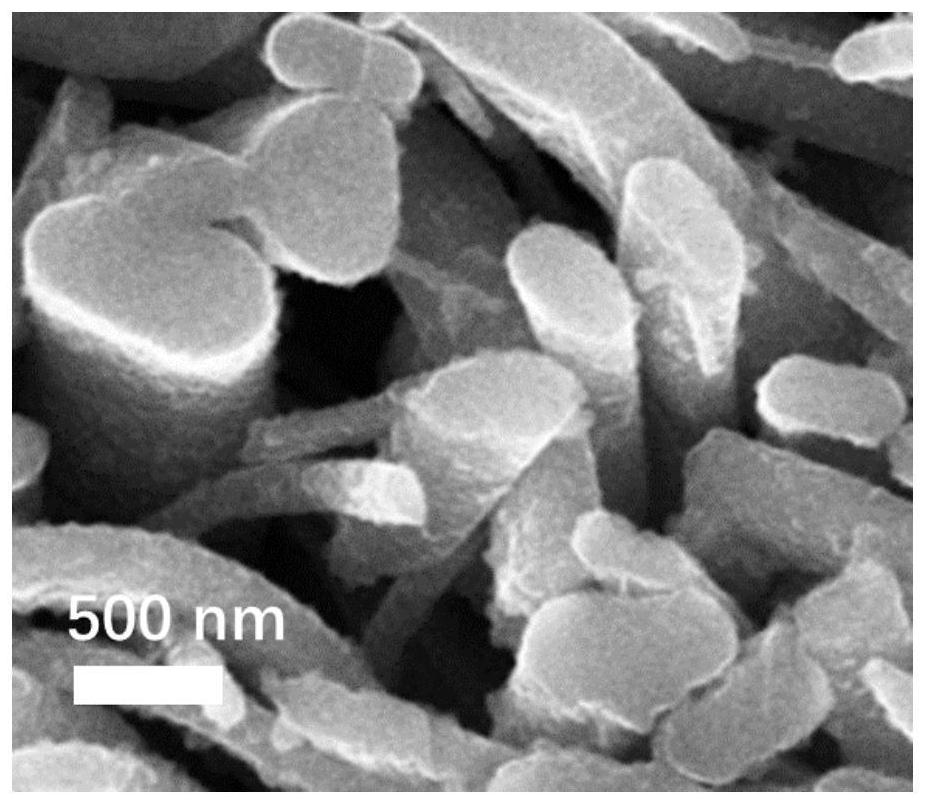

[0183]所含管状纳米纤维为两端封闭的三维骨架层的制备:配制浓度为3重量%的聚偏氟乙烯(PVDF)的N-甲基吡咯烷酮(NMP)溶液,将上述制得的中空的管状纳米纤维材料浸泡于该PVDF溶液中,静置10分钟;然后转移至真空干燥箱中在80℃下真空干燥12小时获得可用于负极极片的三维骨架层。

[0184]将所述三维骨架层、锂箔、负极集流体铜箔按顺序堆叠并冷压后,形成负极极片。之后,对负极极片冷压补锂,补锂层厚度为20μm,直接冲切成直径为(18mm)的圆片待用。

[0185]本实施例中,三维骨架层中的亲锂材料含量为32重量%,三维骨架层厚度为60μm,锂箔的厚度为20μm,铜箔的厚度为12μm,三维骨架层孔隙率为85%。

[0186]2.正极极片制备

[0187]将正极活性材料磷酸铁锂(LiFePO4)、导电炭黑(Super P)、聚偏氟乙烯(PVDF)按照重量比97.5:1.0:1.5进行混合,然后加入到作为溶剂的N-甲基吡咯烷酮(NMP)中,调配成为固含量为75重量%的浆料,并搅拌直至均匀。将浆料均匀涂覆在正极集流体铝箔上,90℃下烘干,得到正极极片,其负载量为1mAh / cm2。将极片裁切成(14mm)的规格待用。

[0188]3.电解液的制备

[0189]在干燥氩气气氛中,首先将二氧环戊烷、二甲醚以1:1的体积比混合,然后在有机溶剂中加入双三氟甲烷磺酰亚胺锂溶解并混合均匀,得到锂盐的浓度为1M的电解液。

[0190]4.锂金属电池的制备

[0191]选用厚...

Example Embodiment

[0192]实施例2

[0193]与实施例1的制备方法相同,不同之处在于:实施例2中的所含管状纳米纤维为两端封闭的三维骨架层如下制备:

[0194]使用浓度为3重量%的聚丙烯腈(PAN)的N-甲基吡咯烷酮溶液。

[0195]本实施例中,三维骨架层中的亲锂材料含量为32重量%,三维骨架层厚度为60μm,锂箔的厚度为20μm,铜箔的厚度为12μm,三维骨架层孔隙率为85%。

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com