Method for quantitatively evaluating coverage rate of zinc phosphating film of cold-rolled automobile steel

A quantitative evaluation, automotive steel technology, applied in the coverage measurement evaluation, phosphating film compactness field, can solve the problem of non-professionals difficult to complete, the operation method process is complicated, etc. problem, to achieve the effect of improving the performance detection and corrosion resistance detection, and the calculation method is simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Cut the cold-rolled automobile sheet after zinc phosphating treatment into samples with a length of 20mm and a width of 15mm, and clean the surface of the samples with alcohol.

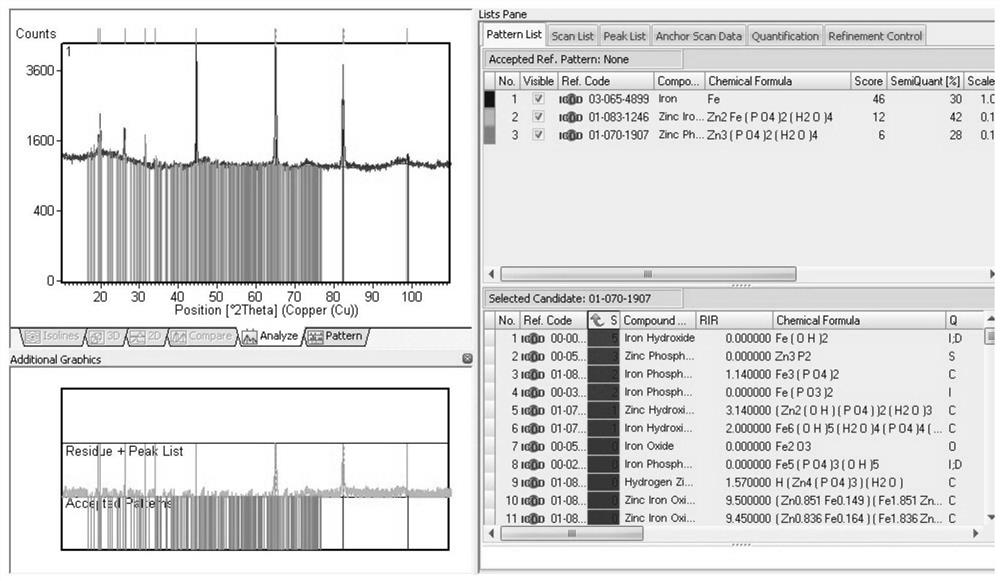

[0020] 2. The phase quantification function of the X-ray diffractometer was used to determine the phase composition of the phosphating film on the surface of the cold-rolled automobile steel sample. The working conditions were Cu target, voltage 40kV, current 40mA, continuous scanning, each step for 20.4s, step Length 0.026° / step.

[0021] 3. The phase test results are as follows figure 1 As shown, the phosphating film coverage is calculated from this, and the phosphating film coverage = (the third generation of zinc phosphate Zn 3 (PO 4 ) 2 ·4H 2 O + iron zinc phosphate Fe 2 Zn(PO 4 ) 2 ·4H 2 O) Percentage / 3rd Generation Zinc Phosphate Zn 3 (PO 4 ) 2 ·4H 2 O + iron zinc phosphate Fe 2 Zn(PO 4 ) 2 ·4H 2 O+Fe) percentage, the results are shown in Table 1 below.

Embodiment 2

[0023] 1. Cut the cold-rolled automobile sheet after zinc phosphating treatment into samples with a length of 20mm and a width of 15mm, and clean the surface of the samples with alcohol.

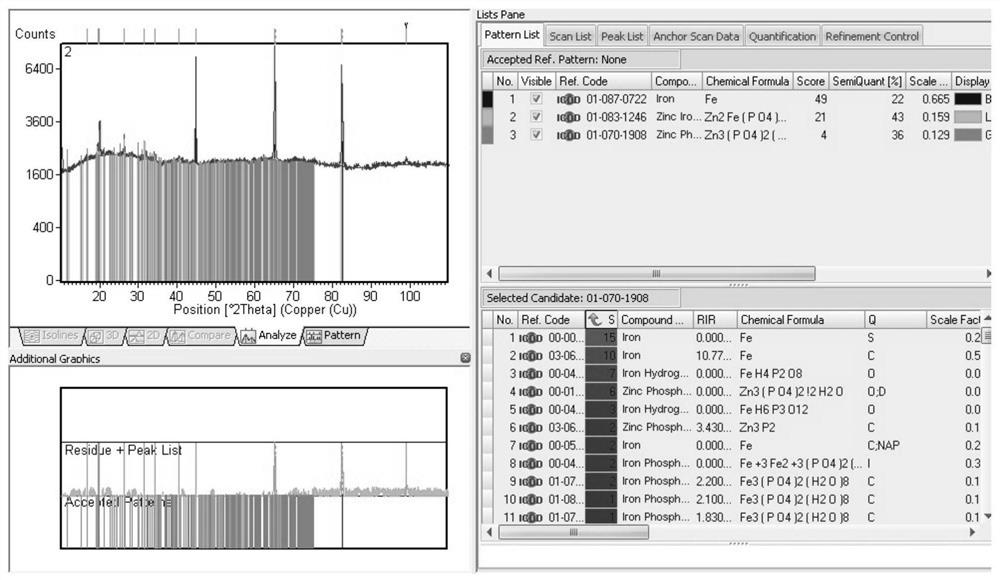

[0024] 2. The phase quantification function of the X-ray diffractometer was used to determine the phase composition of the phosphating film on the surface of the cold-rolled automobile steel sample. The working conditions were Cu target, voltage 40kV, current 40mA, continuous scanning, each step for 20.4s, step Length 0.026° / step.

[0025] 3. The phase test results are as follows figure 2 As shown, calculate the phosphating film coverage, the phosphating film coverage = (the third generation of zinc phosphate Zn 3 (PO 4 ) 2 ·4H 2 O + iron zinc phosphate Fe 2 Zn(PO 4 ) 2 ·4H 2 O) Percentage / 3rd Generation Zinc Phosphate Zn 3 (PO 4 ) 2 ·4H 2 O + iron zinc phosphate Fe 2 Zn(PO 4 ) 2 ·4H 2 O+Fe) percentage, the results are shown in Table 1 below.

Embodiment 3

[0027] 1. Cut the cold-rolled automobile sheet after zinc phosphating treatment into samples with a length of 20mm and a width of 15mm, and clean the surface of the samples with alcohol.

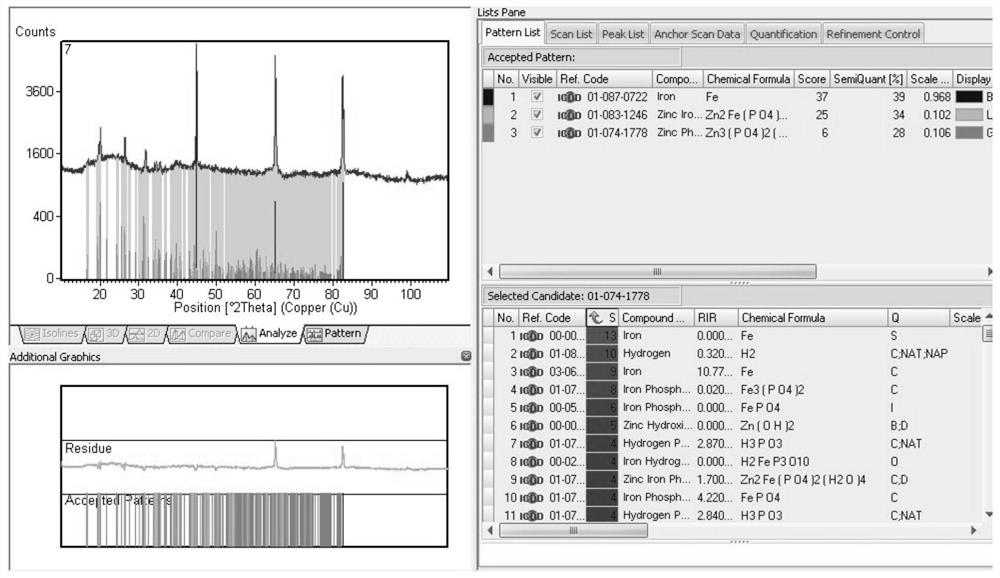

[0028] 2. The phase quantification function of the X-ray diffractometer was used to determine the phase composition of the phosphating film on the surface of the cold-rolled automobile steel sample. The working conditions were Cu target, voltage 40kV, current 40mA, continuous scanning, each step for 20.4s, step Length 0.026° / step.

[0029] 3. The phase test results are as follows image 3 As shown, calculate the phosphating film coverage, the phosphating film coverage = (the third generation of zinc phosphate Zn 3 (PO 4 ) 2 ·4H 2 O + iron zinc phosphate Fe 2 Zn(PO 4 ) 2 ·4H 2 O) Percentage / 3rd Generation Zinc Phosphate Zn 3 (PO 4 ) 2 ·4H 2 O + iron zinc phosphate Fe 2 Zn(PO 4 ) 2 ·4H 2 O+Fe) percentage, the results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com