Preparation method and application of nitrogen-doped carbon-coated sodium-rich sodium cobalt ferricyanide material

A nitrogen-doped carbon and sodium cyanide technology, applied in nanotechnology, electrochemical generators, positive electrodes, etc. for materials and surface science, can solve problems such as the application of difficult solid-state sodium-ion batteries, and achieve good cycle stability properties, increasing the reversible specific capacity, and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035]实施例1

[0036]一种富钠态Na2CoFe(CN)6-NC材料的制备方法,其步骤如下:

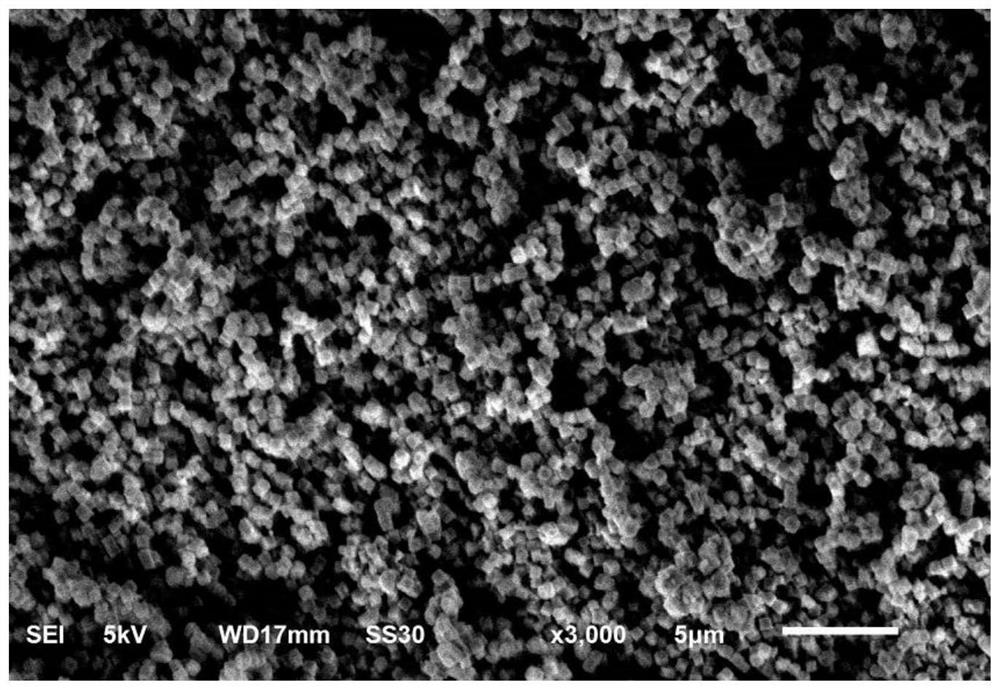

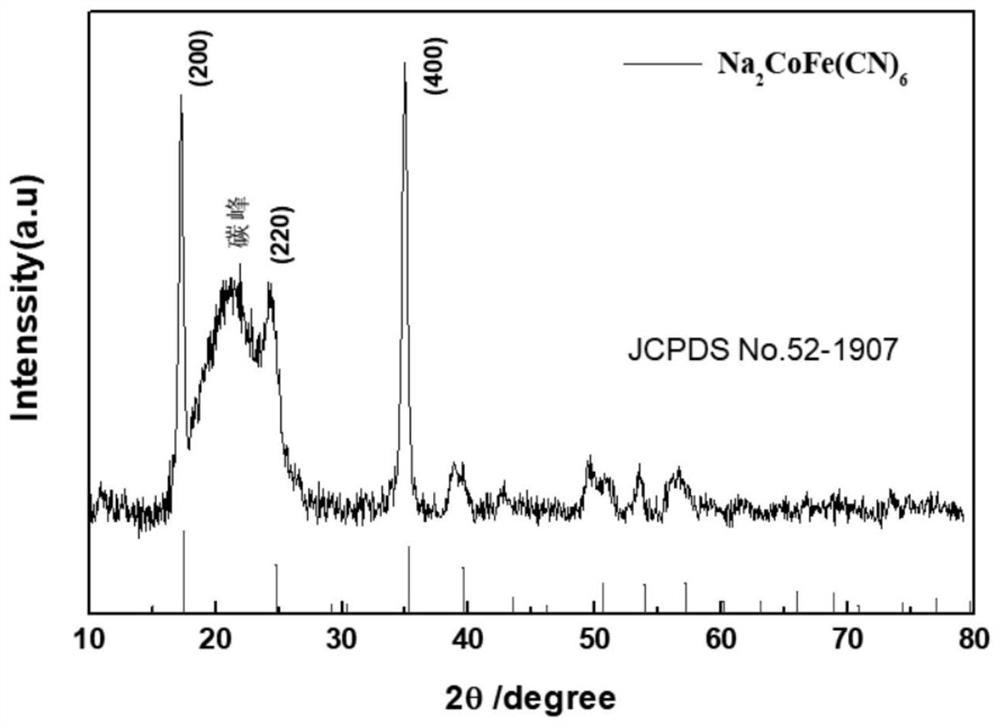

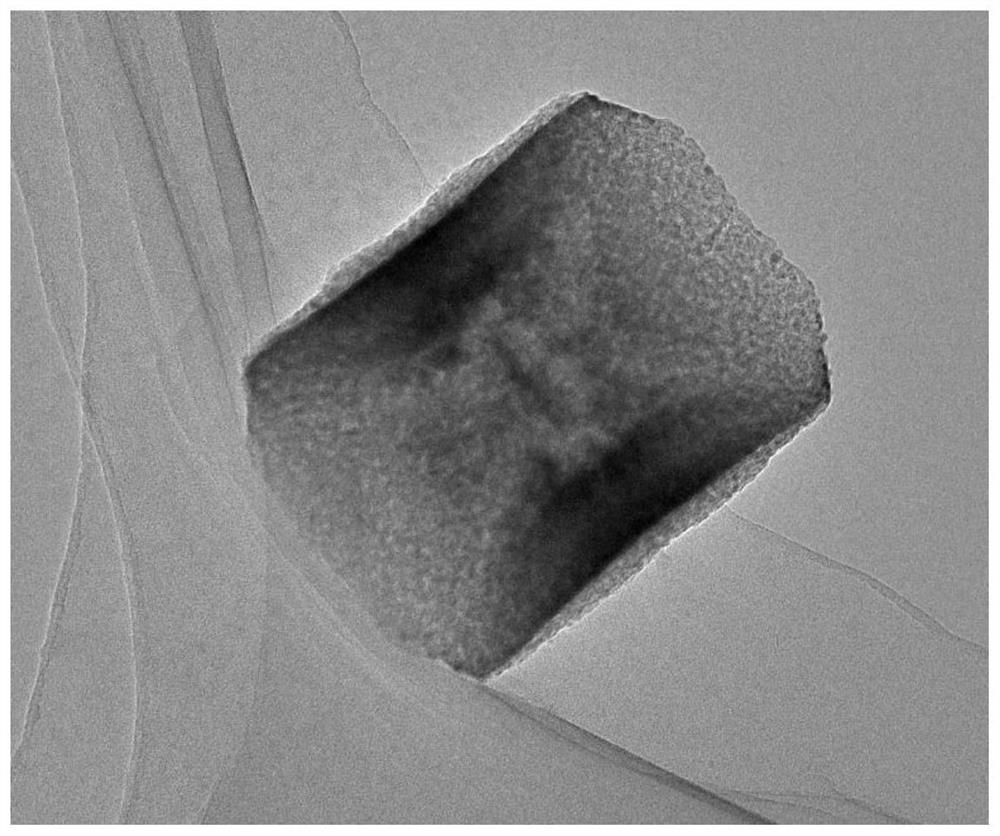

[0037]将0.48g六水合氯化钴(0.002mol)和3.5g聚乙烯吡咯烷酮(平均相对分子质量24000)溶于50mL蒸馏水中,得到溶液a;将0.33g铁氰化钾(0.001mol)溶于50mL蒸馏水中,得到溶液b,然后用蠕动泵以5mL / min的速率将溶液b抽入溶液a中进行混合,再充分搅拌12h得到混合溶液;先将混合溶液在25℃下陈化72h,然后离心,用乙醇洗涤3次,再100℃烘干,得到固体粉末;将固体粉末在马弗炉200℃中先热处理2h,再300℃热处理0.5h,冷却至室温后,得到前驱体粉体。将得到的前驱体粉体与50mg磷酸氢二钠在氩气条件下350℃保温3h,冷却至室温后,得到富钠态Na2CoFe(CN)6-NC电极材料。

Example Embodiment

[0038]实施例2

[0039]一种富钠态Na2CoFe(CN)6-NC材料的制备方法,其步骤如下:

[0040]将0.48g六水合氯化钴(0.002mol)和4.8g聚乙烯吡咯烷酮(平均相对分子质量24000)溶于50mL蒸馏水中,得到溶液a;将0.33g铁氰化钾(0.001mol)溶于50mL蒸馏水中,得到溶液b,然后用蠕动泵以5mL / min的速率将溶液b抽入溶液a中进行混合,再充分搅拌12h得到混合溶液;先将混合溶液在25℃下陈化72h,然后离心,用乙醇洗涤3次,再100℃烘干,得到固体粉末;将固体粉末在马弗炉200℃中先热处理2h,再300℃热处理0.5h,冷却至室温后,得到前驱体粉体。将得到的前驱体粉体与50mg磷酸氢二钠在氩气条件下350℃保温3h,冷却至室温后,得到富钠态Na2CoFe(CN)6-NC电极材料。

Example Embodiment

[0041]实施例3

[0042]一种富钠态Na2CoFe(CN)6-NC材料的制备方法,其步骤如下:

[0043]将0.48g六水合氯化钴和6.5g聚乙烯吡咯烷酮(平均相对分子质量24000)溶于50mL蒸馏水中,得到溶液a;将0.33g铁氰化钾溶于50mL蒸馏水中,得到溶液b,然后用蠕动泵以5mL / min的速率将溶液b抽入溶液a中进行混合,再充分搅拌12h得到混合溶液;先将混合溶液在25℃下陈化48h,然后离心,用乙醇洗涤3次,再100℃烘干,得到固体粉末;将固体粉末在马弗炉200℃中先热处理2h,再300℃热处理0.5h,冷却至室温后,得到前驱体粉体。将得到的前驱体粉体与50mg磷酸氢二钠在氩气条件下350℃保温3h,冷却至室温后,得到富钠态Na2CoFe(CN)6-NC电极材料。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com