Numerical control machine tool cooling circulation structure and numerical control machine tool

A cooling cycle, CNC machine tool technology, applied in the direction of metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problem of not meeting the heat dissipation requirements, and achieve the effect of maintaining continuous flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

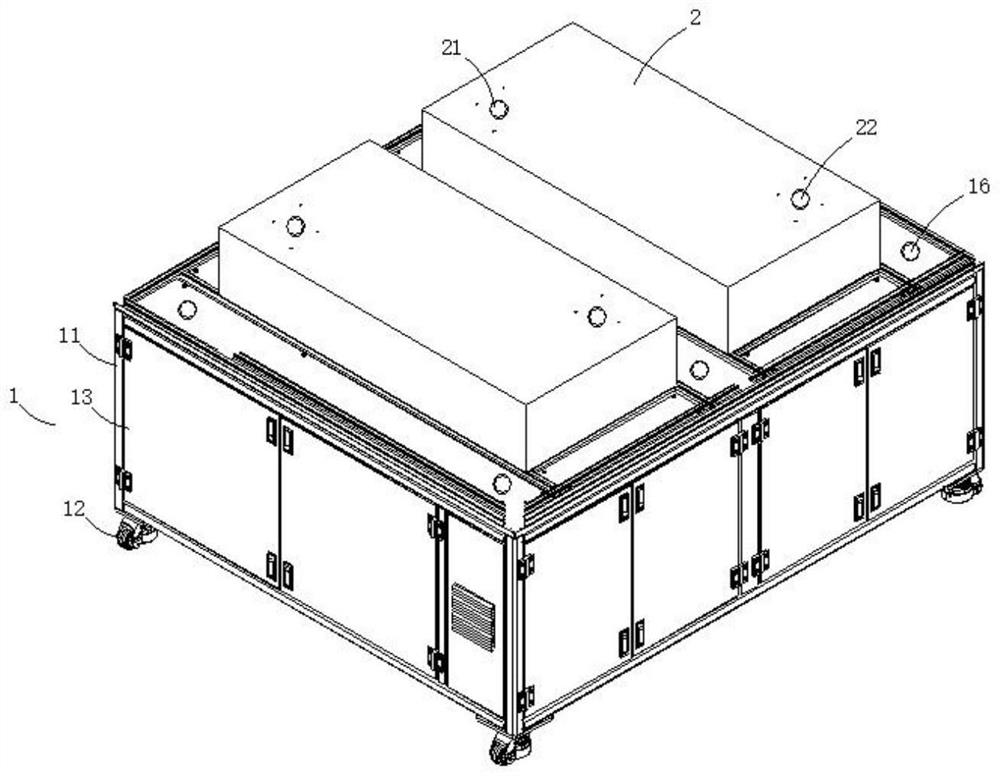

[0023] like figure 1 and figure 2 As shown, the cooling cycle mounting base 1 according to the embodiment of the present invention includes a mounting base body 11 and a moving universal wheel 12. The moving universal wheel 12 can be installed at the bottom end of the mounting base body 11 by bolting. When moving the cooling cycle installation base 1 to different CNC machine tools, it can be guided by moving the universal wheel 12, and a plurality of maintenance sealing door bodies 13 can be installed on the outer peripheral side of the installation base body 11 by hinged connection. When the interior of the cooling cycle installation base 1 needs to be inspected, the inspection sealing door 13 can be opened.

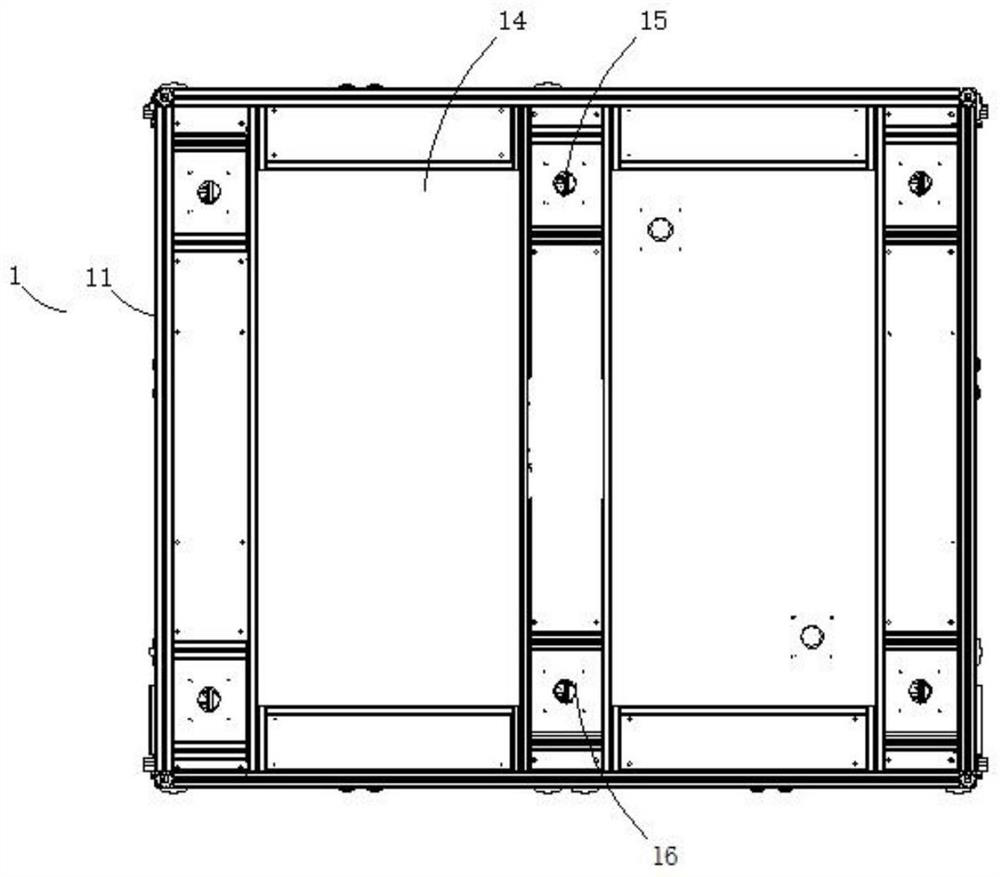

[0024] In order to solve the problem of how to improve the cooling effect and cooling speed of the cooling cycle structure of the CNC machine tool, the cooling cycle cavity 14 can be formed with cavity openings by turning, and the two cavity openings are formed on the...

Embodiment 2

[0031] The numerical control machine tool according to the embodiment of the present invention includes a cooling cycle structure of the numerical control machine tool, and the cooling cycle structure of the numerical control machine tool is the cooling cycle structure of the numerical control machine tool described in any one of the above embodiments.

[0032] It should be noted that, in this document, relational terms such as first and second are only used to distinguish one entity or operation from another entity or operation, and do not necessarily require or imply any relationship between these entities or operations. any such actual relationship or sequence exists.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com