Multi-color covered edge manufacturing process, covered edge product and application of covered edge product

A production process and hemming technology, applied in applications, other home appliances, home appliances, etc., can solve the problems of large hemming curvature, poor hemming effect, and curling, etc., to improve the adhesive tensile strength and beautiful wearing experience. , the effect of high strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

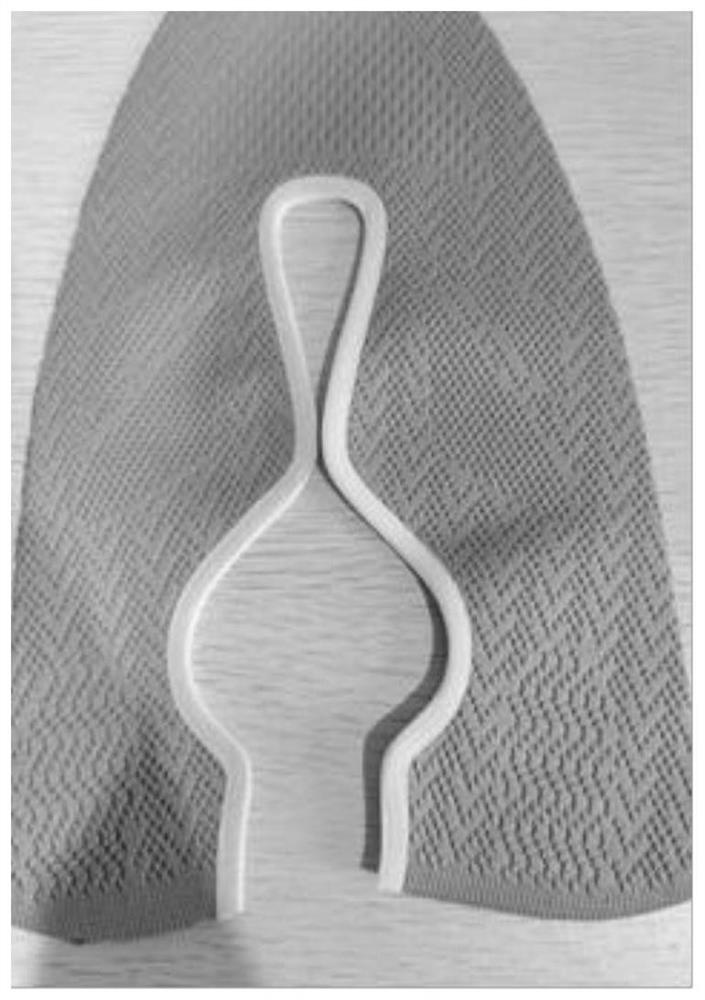

[0049] In an exemplary embodiment of the method according to the present invention, a method such as Figure 5 Upper body shown with multicolor binding. The method specifically contains the following steps:

[0050] According to the shape of the vamp to be hemmed, a hemming hot-cutting mold and a flat ironing peg mold that are adapted to the shape of the vamp to be hemmed are set on the hemming machine. Manufacturing is a very mature technology. According to the cutting design of the upper, it can be entrusted to other open mold main bodies for processing or self-manufactured. Each upper to be hemmed should have a corresponding hemming and hot-cutting mold and a flat ironing peg mold. This can be achieved. Large-scale, repetitive production applications.

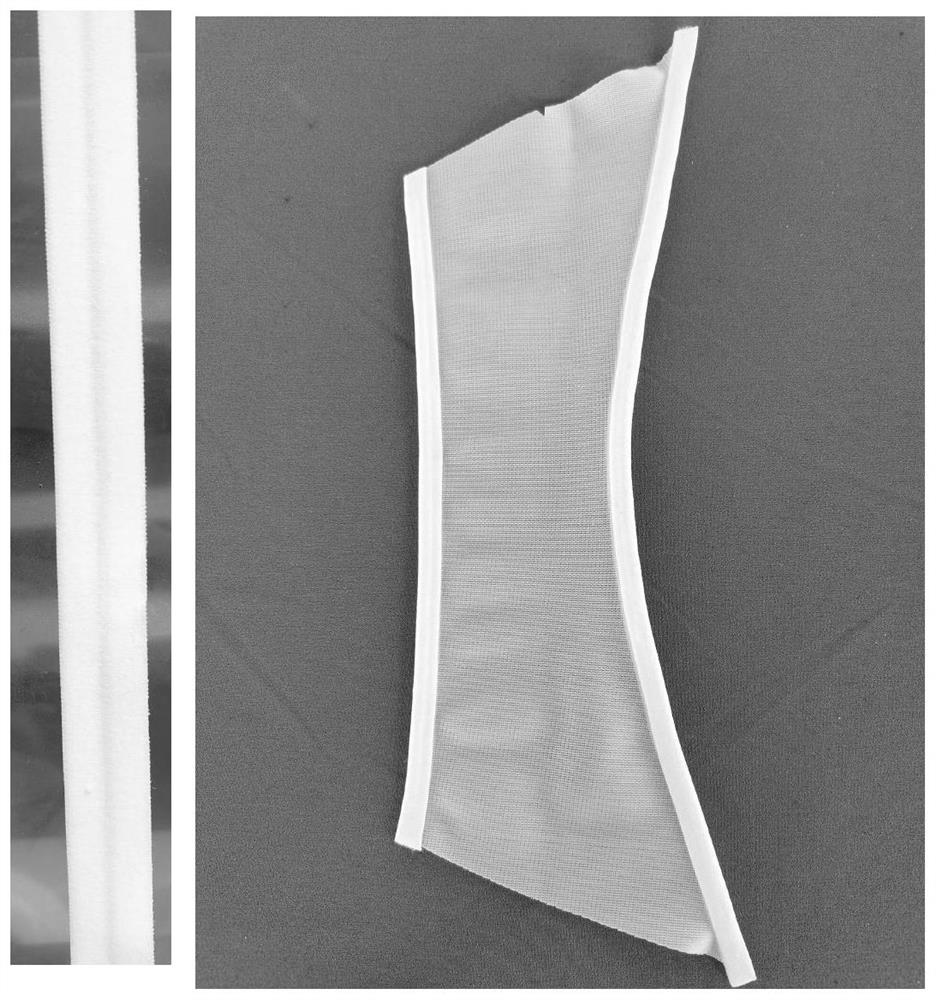

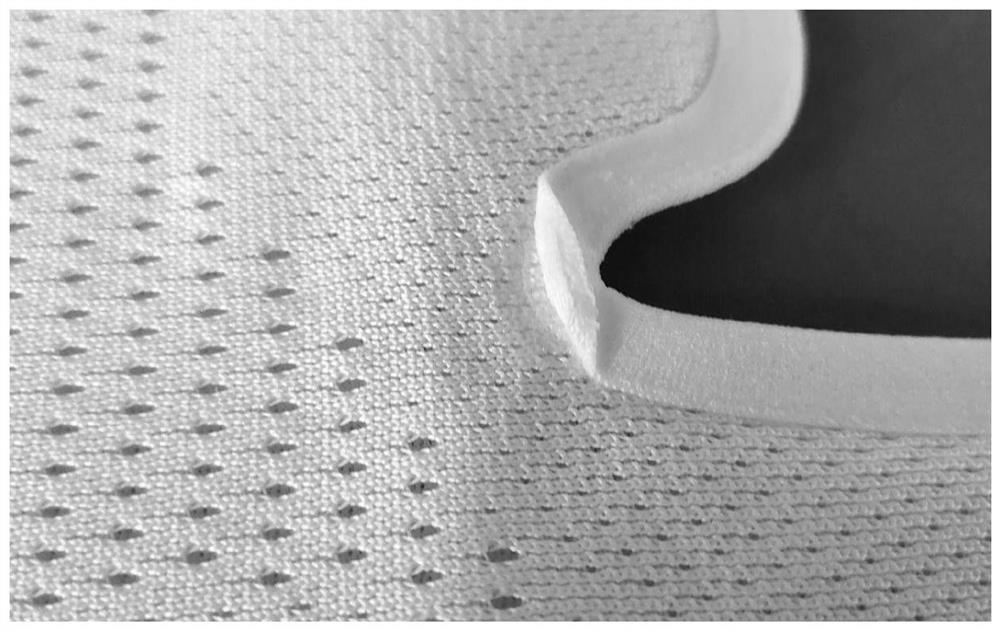

[0051] Take the edge wrapping strip and strip TPU prepared in advance with preset colors and patterns. It should be noted here that the width of the strip TPU should be larger than the width of the edge wrapping strips of ...

Embodiment 2

[0058] Different from the above-mentioned embodiment, a strip of TPU with a width of 12 mm and a thickness of 0.4 mm can also be used to fold in half (then a TPU adhesive strip with a width of about 6 mm is obtained) to cover the edge of the upper to be hemmed, and perform high-frequency eager cutting. Cut off about 3mm wide TPU edging leftovers and remove to obtain the to-be-wrapped shoe upper containing TPU adhesive strips. When performing high-frequency heat cutting, set the fusing temperature to 110°C, the fusing time to 5s, the cooling temperature to 30°C, the cooling time to 6s, and the pressure to be 4MPa.

[0059]Fold the hemming strip with the preset color and pattern with a width of 6mm in half (then get the hemming with color and pattern with a width of about 3mm) and wrap it on the to-be-wrapped shoe containing the TPU adhesive strip obtained in the previous step The edge of the surface is wrapped and hot pressed in turn. During hemming, set the heating temperatur...

Embodiment 3

[0061] Different from the method of Embodiment 1, this embodiment adopts a strip of TPU with a width of 14 mm and a thickness of 0.5 mm to be folded in half (then a TPU adhesive strip with a width of about 7 mm is obtained) to cover the edge of the vamp to be hemmed, and the height is applied. Frequently and eagerly, cut off about 2mm wide TPU edging and leftovers to get the upper to be edging containing TPU adhesive strips. When performing high-frequency heat cutting, set the fusing temperature to 100°C, the fusing time to 6s, the cooling temperature to 25°C, the cooling time to 7s, and the pressure to be 4MPa.

[0062] Fold the hemming strip with the preset color and pattern with a width of 9mm in half (then get the hemming with color and pattern with a width of about 4.5mm) and wrap it on the to-be-wrapped edge containing the TPU adhesive strip obtained in the previous step The edge of the upper is wrapped and hot pressed in turn. During hemming, set the heating temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com