High-performance waterborne epoxy modified emulsified asphalt micro-surfacing material and preparation method thereof

A technology of emulsified asphalt and water-based epoxy, which is applied to cohesive pavement, roads, buildings and other directions paved on site. It can solve problems such as poor adhesion, poor anti-rutting ability of micro-surfaces, and rutting diseases, and achieve excellent performance. Effects of long-term wear resistance, improved rutting resistance, and improved interlayer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

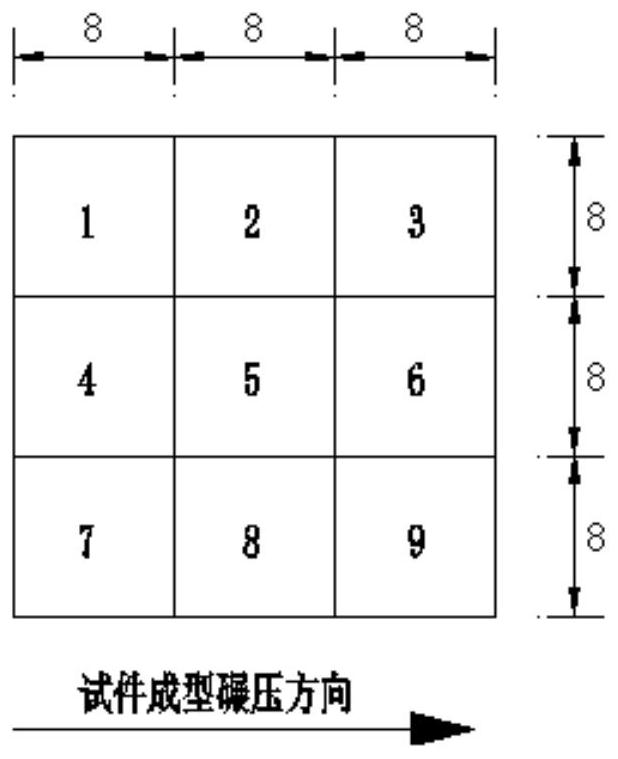

Image

Examples

Embodiment 1

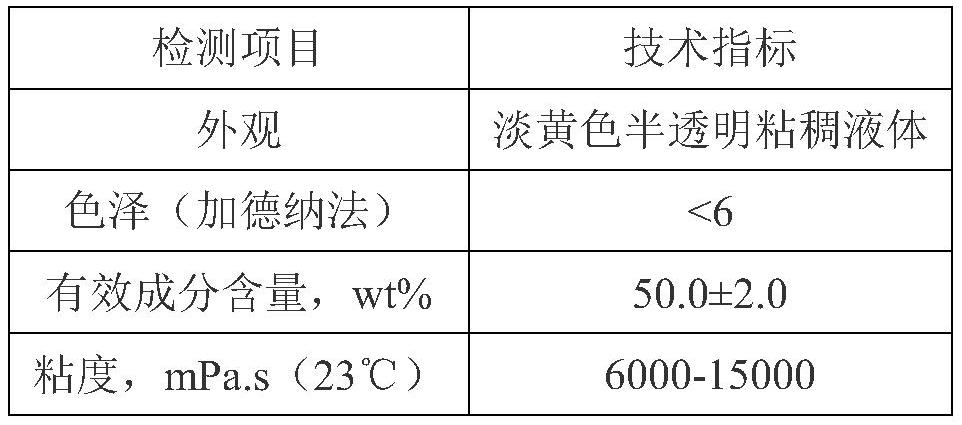

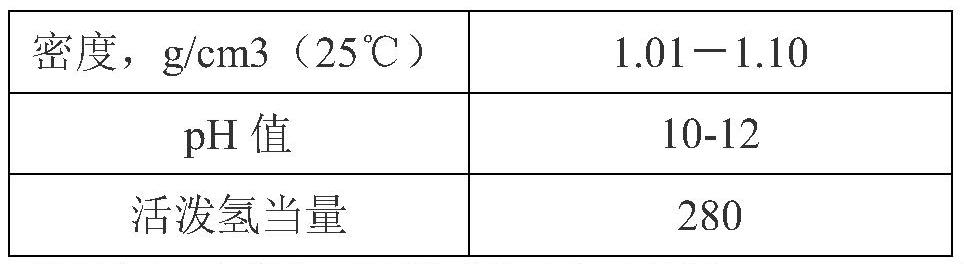

[0060] The high-performance water-based epoxy modified emulsified asphalt micro-surface material provided in this example, the raw materials include mineral aggregate, water-based epoxy modified emulsified asphalt, cement, aluminum dihydrogen phosphate in a weight ratio of 100:10:2:5:8 and water; the water-based epoxy modified emulsified asphalt comprises a non-ionic water-based epoxy resin emulsion, a non-ionic vinylamine-polyether polyol addition curing agent (model EM) in a weight ratio of 3:3:4:6:100 -310), SBR styrene-butadiene latex, modified silica, cationic emulsified asphalt.

[0061] The preparation method of modified white carbon black is as follows: weighing white carbon black and trimesic acid in a weight ratio of 1.5:1, dissolving the trimesic acid in water, then adding white carbon black and mixing evenly, and sealing at about 85°C. The reaction was stirred in the environment for 25 min, and after filtration, the filter residue was washed with absolute ethanol, ...

Embodiment 2

[0066] The high-performance water-based epoxy modified emulsified asphalt micro-surface material provided in this example, the raw materials include mineral aggregate, water-based epoxy modified emulsified asphalt, cement, aluminum dihydrogen phosphate in a weight ratio of 100:10:2:5:8 and water; the water-based epoxy modified emulsified asphalt comprises a non-ionic water-based epoxy resin emulsion, a non-ionic vinylamine-polyether polyol addition curing agent (model EM) in a weight ratio of 3:3:4:6:100 -310), SBR styrene-butadiene latex, modified silica, cationic emulsified asphalt.

[0067] The preparation method of modified white carbon black is as follows: weighing white carbon black and trimesic acid in a weight ratio of 1:1, dissolving the trimesic acid in water, then adding white carbon black and mixing evenly, and sealing at about 90°C. The reaction was stirred in the environment for 20 min, and after filtration, the filter residue was washed with absolute ethanol, an...

Embodiment 3

[0072] The high-performance water-based epoxy modified emulsified asphalt micro-surface material provided in this example, the raw materials include mineral aggregate, water-based epoxy modified emulsified asphalt, cement, aluminum dihydrogen phosphate in a weight ratio of 100:14:4:6:5 and water; the water-based epoxy modified emulsified asphalt comprises a non-ionic water-based epoxy resin emulsion, a non-ionic vinylamine-polyether polyol addition curing agent (model EM) in a weight ratio of 6:6:2:4:100 -310), SBR styrene-butadiene latex, modified silica, cationic emulsified asphalt.

[0073] The preparation method of modified white carbon black is as follows: weighing white carbon black and trimesic acid in a weight ratio of 1.5:1, dissolving the trimesic acid in water, then adding white carbon black and mixing evenly, and sealing at about 70°C. The reaction was stirred for 30 min in the environment, and after filtration, the filter residue was washed with absolute ethanol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com