Distributed electric contact water level gauge measuring system and control method thereof

A measurement system and electric contact technology, applied in the direction of computer control, program control, general control system, etc., can solve the problems of increasing the monitoring intensity of operating personnel, difficult control, and inconsistent signal configuration, so as to reduce the failure rate of boiler startup , obvious direct economic benefits, and the effect of reducing the rate of water level accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

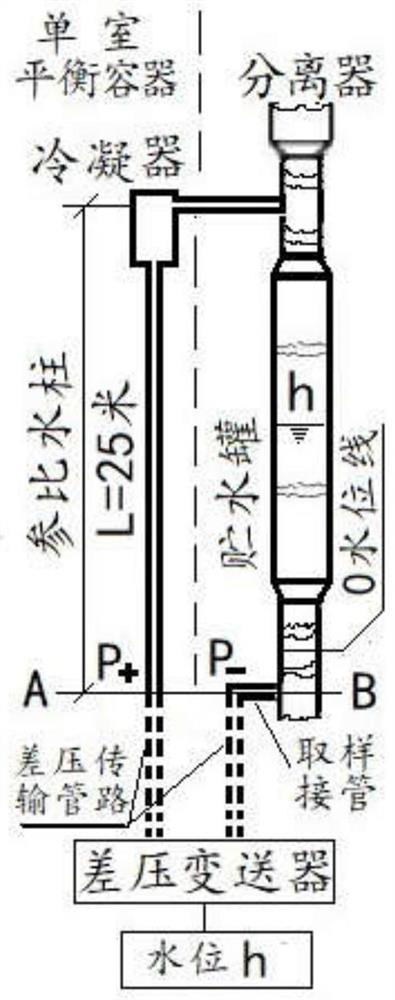

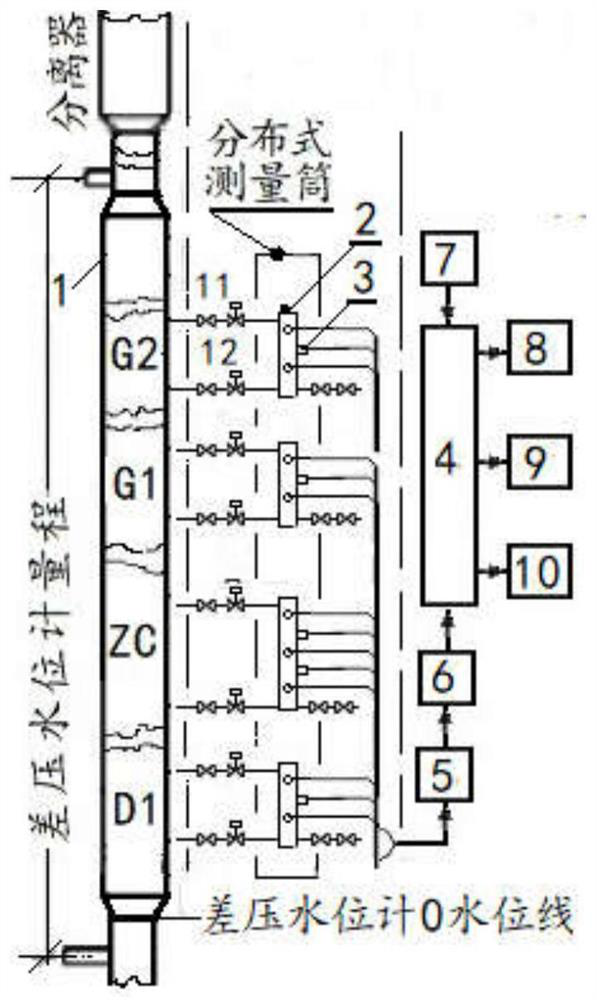

[0029] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

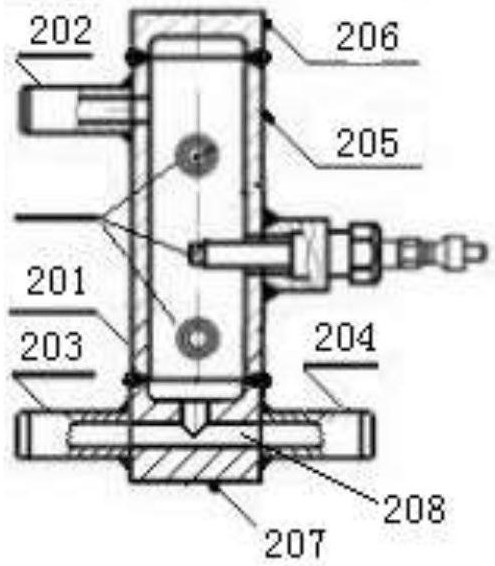

[0030] like figure 2 As shown in the figure, a distributed electric contact water level meter measurement system of the present invention includes several sampling short cylinders 2, several electrodes 3, a single-chip microcomputer 4, a multi-point switch circuit module 5, an A / D conversion module 6, and a keyboard input module 7. , water level display module 8, water level ladder analog output module 9, switch output module 10, manual cut-off valve 11 and remote control electric cut-off valve 12.

[0031] In the present invention, a plurality of short sampling cylinders 2 are sequentially distributed along the axial direction of the container under test 1. The midpoint of the sampling range of each sampling short cylinder 2 is at the same height as each key point of water level control in the container under test 1. The container under test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com