Color and gloss detection equipment and detection method thereof

A technology of color detection and detection equipment, which is applied in the direction of color/spectral characteristic measurement, color measurement device, scattering characteristic measurement, etc. It can solve problems such as eye damage, high misjudgment rate, and poor enthusiasm of personnel, and achieve high detection accuracy and detection High efficiency, realize the effect of automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

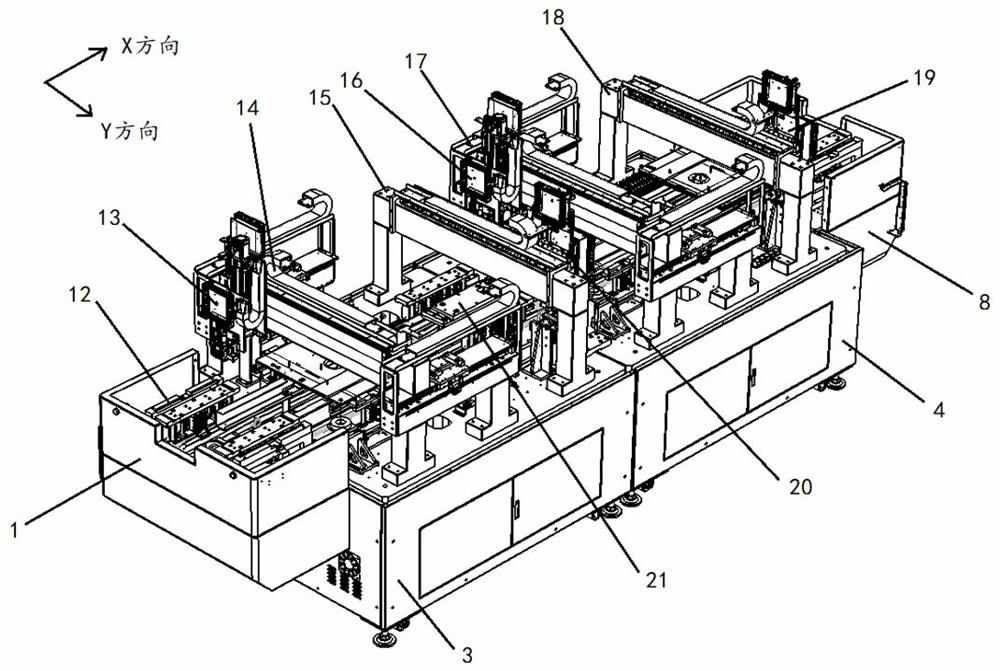

[0039] Further, after the PAD device 37 is placed on the feeding and conveying module 12, when the grating 2 detection personnel keep their hands away from the feeding mechanism 1, and press the start button 101 with both hands at the same time, the color gloss detection device can be started. This startup method is more secure.

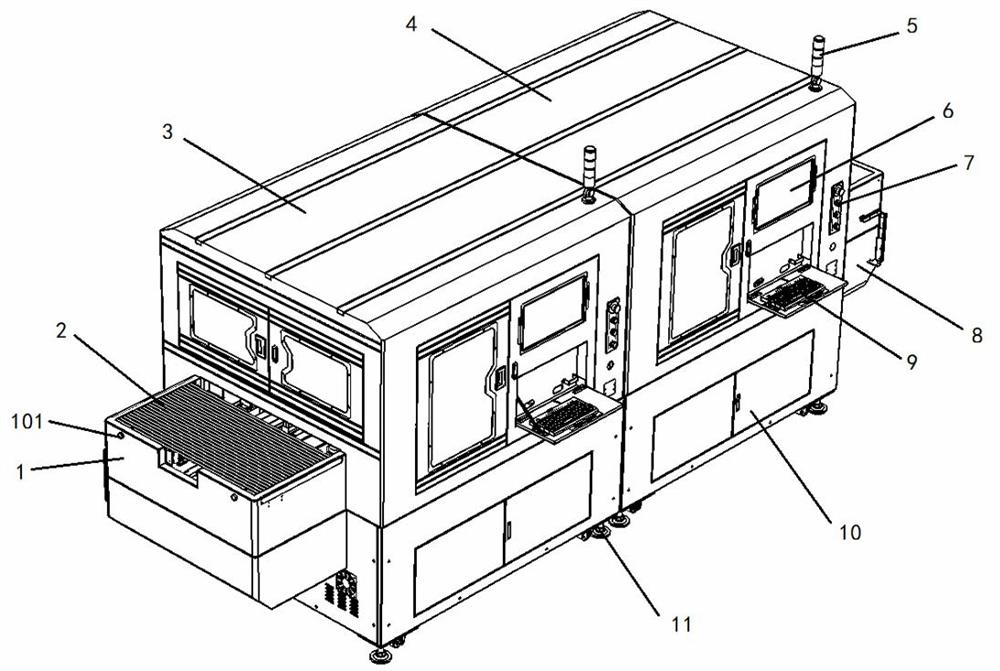

[0040] Further, the tops of the color detection device 3 and the gloss detection device 4 are provided with a three-color lamp 5, the tri-color lamp 5 is used to display the operating status of the color detection device 3 and the gloss detection device 4, and a display screen is arranged on one side of the color detection device 3 6. A control button 7 is provided on one side of the display screen 6, and the display screen 6 is connected to the operation panel 9, and the operation of the color detection device 3 is controlled through the operation panel 9. The display screen 6 displays the operating parameters of the color detection device 3, and at ...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com