Planning system and method for processing workpiece

A technology for planning systems and workpieces, applied in the field of manufacturing systems, can solve problems such as high cost, low production volume, and insufficient utilization of factory resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

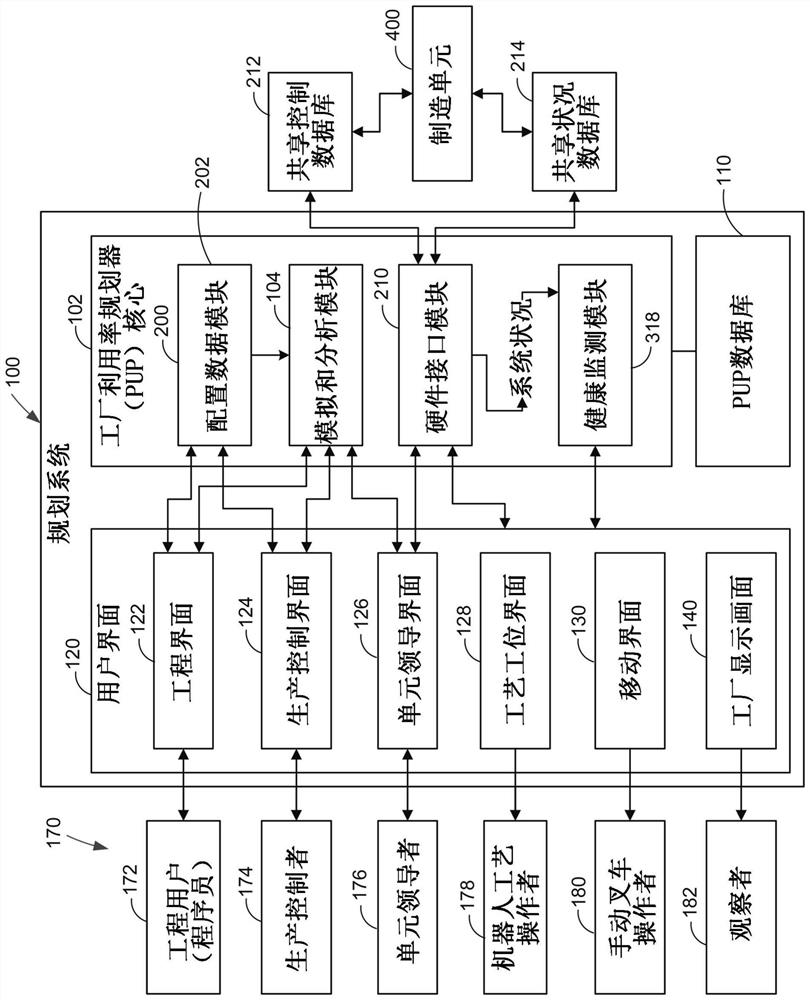

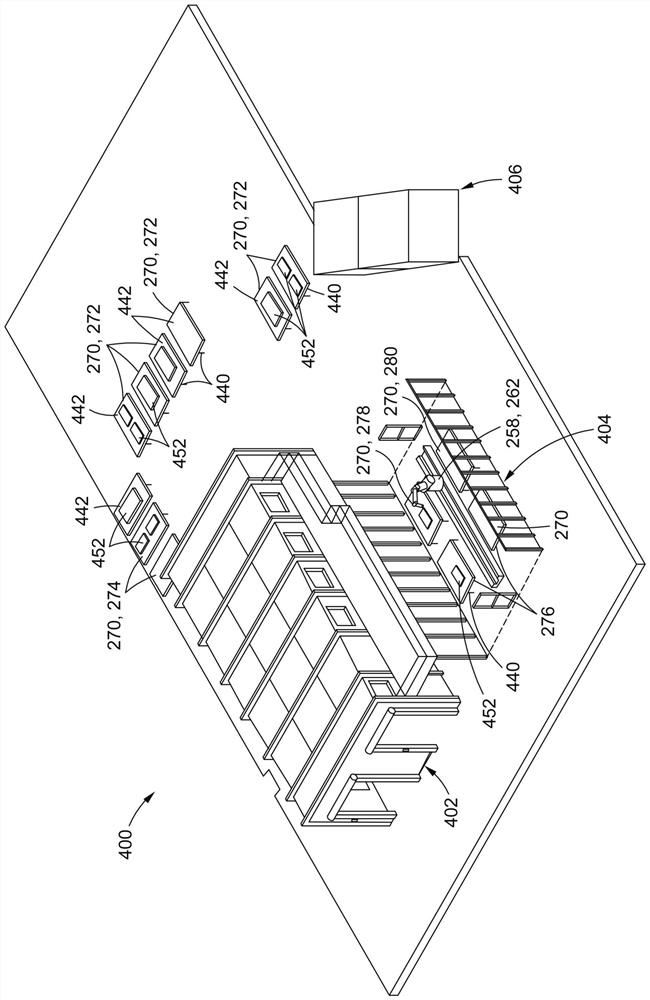

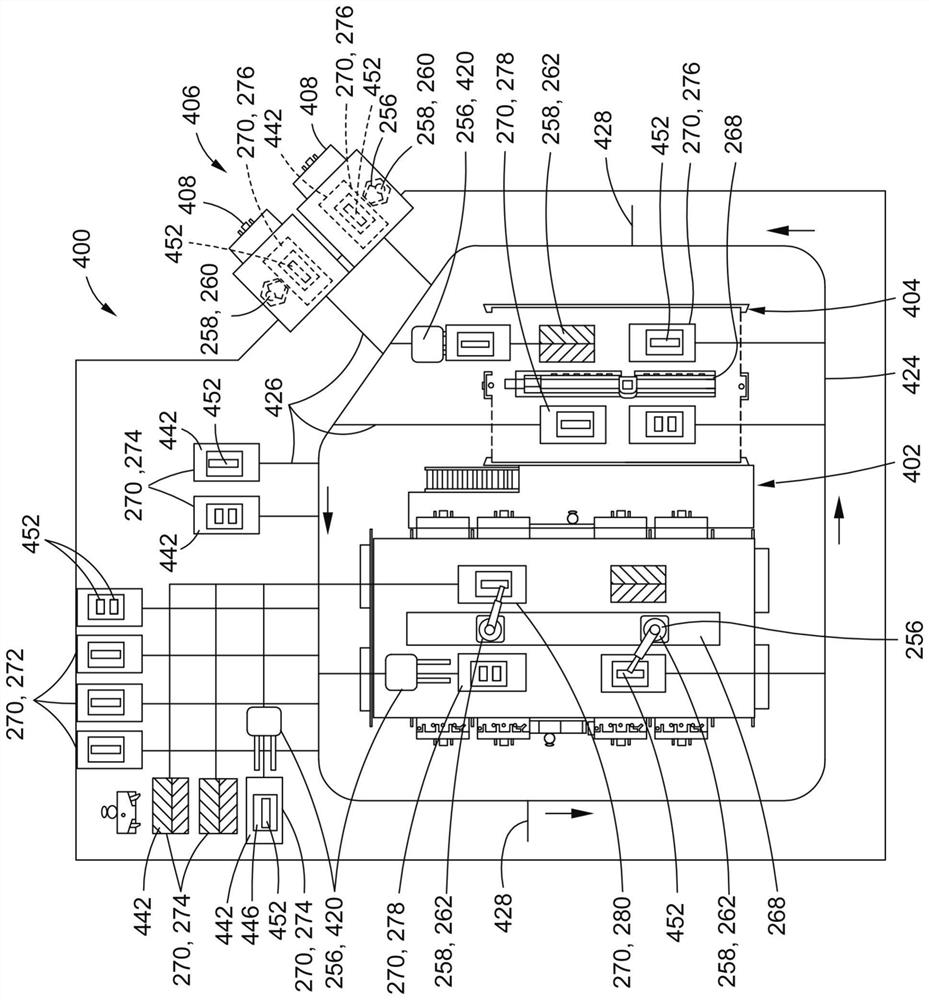

[0033] Referring now to the accompanying drawings which illustrate preferred and various examples of the present disclosure, figure 1 Shown is a manufacturing cell 400 used to simulate a factory (not shown) (eg, Figure 2 to Figure 3 ) for multiple workpieces 452 ( Image 6) is a block diagram of a planning system 100 for processing. The presently disclosed planning system 100 simulates workpiece processing in any of a number of different manufacturing cell configurations and / or plant configurations, and is not limited to Figure 2 to Figure 9 The processing of workpieces in the illustrated manufacturing cell is simulated. The planning system 100 provides means for determining the total amount of time (ie, completion time) required to complete processing of all workpieces 452 in the workpiece sequence. Manufacturing cell 400 includes operators 258 ( image 3 and Figure 12 ). Operators 258 include human operators as described below (eg, technician 260, see image 3 ) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com