Inventory stagnant material reason tracing method and system based on big data

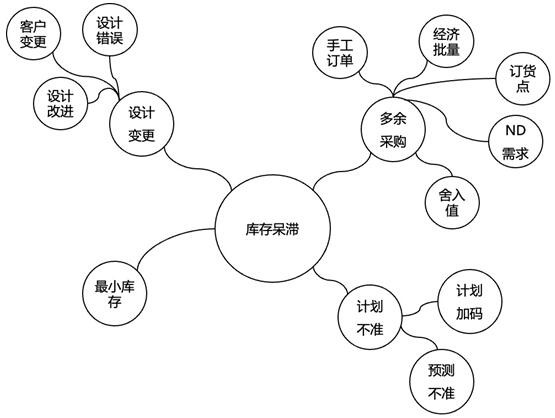

A traceability system and big data technology, applied in the field of big data processing, can solve the problems of reducing inventory costs, difficult to identify the source or responsible department of sluggish materials, and extensive management of sluggish materials in inventory, so as to reduce inventory costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

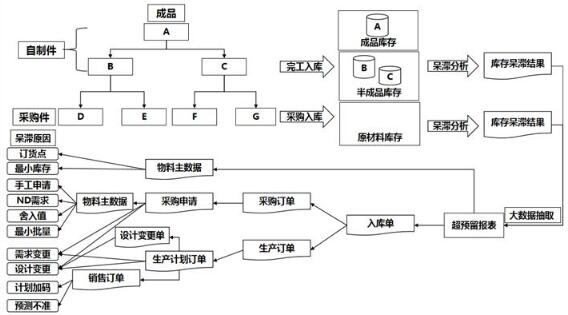

[0055] For example, find the last stock-in document through the stock-in record, find the purchase order or production order through the stock-in document, and then get the purchase requisition or production plan order based on the purchase order or production order. If the purchase requisition or production plan order If the quantity is a multiple of the rounding value (rounding value > 1) and the actual required quantity is less than the purchase requisition quantity or planned order quantity, then output the sluggish reason "rounding value".

[0056] The minimum batch size and rounding value of SAP materials: when the minimum batch size is less than 2 times the rounding value, the planning order will be generated according to the multiple of the rounding value. If the minimum batch size is greater than 2 times the rounding value, the planning sheet will be generated considering the minimum batch size.

[0057] SAP access logic:

[0058] b) Obtain the purchase order quantity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com