Compound seasoning production equipment with impurity removal function

A compound seasoning and production equipment technology, which is applied in the field of seasoning production, can solve the problems affecting the taste of compound seasoning, and achieve the effect of avoiding stem and leaf tearing, waste of raw materials, and cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

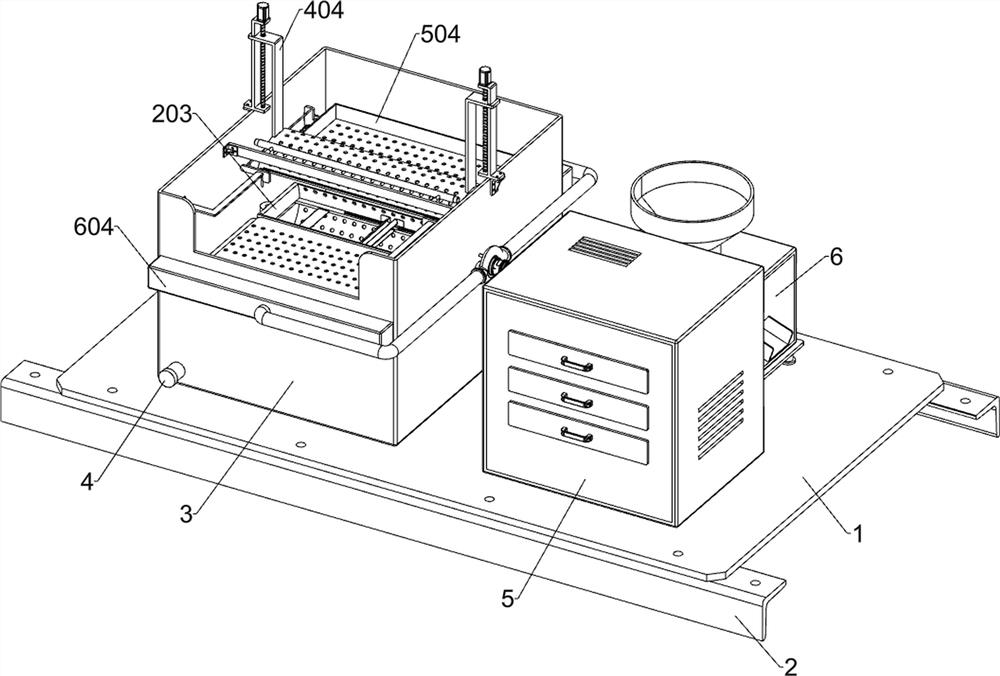

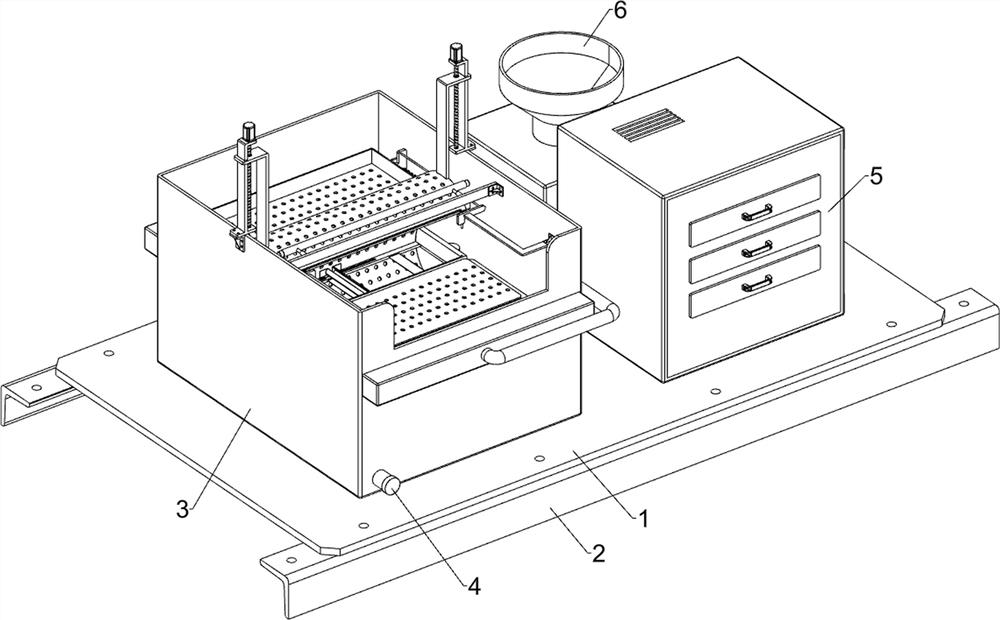

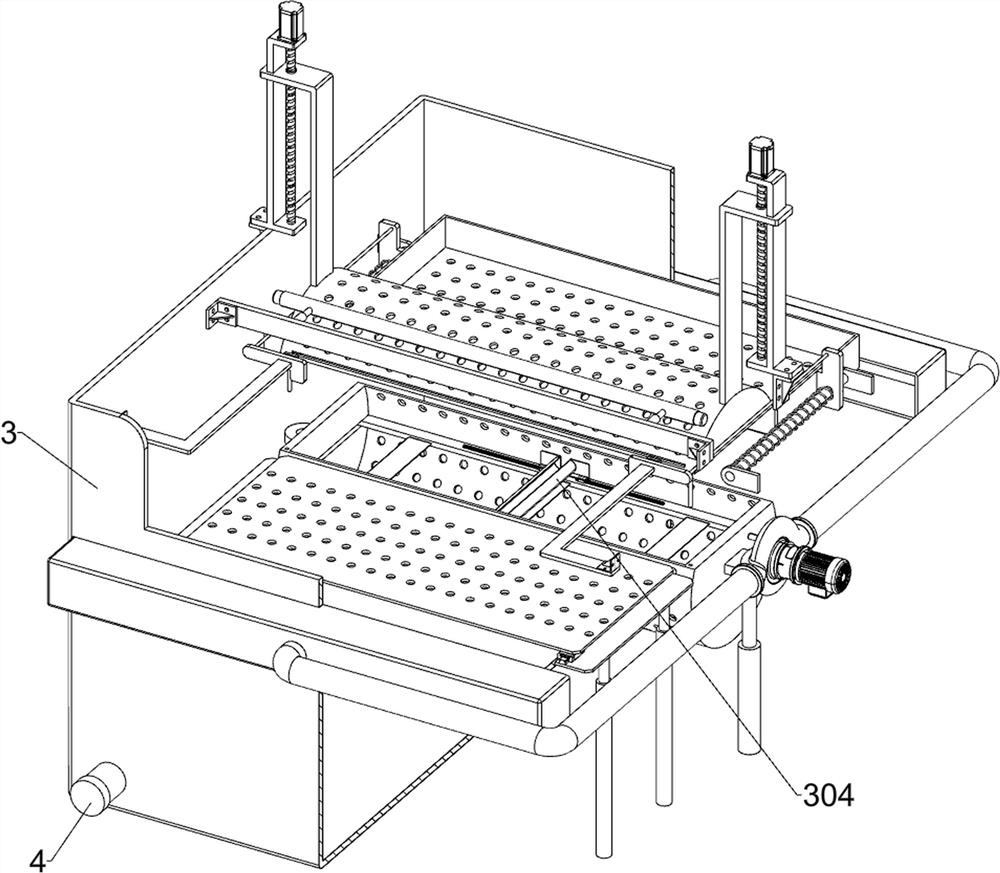

[0032] A compound seasoning production equipment with impurity removal function, such as Figure 1-11As shown, it includes a bottom plate 1, a first support frame 2, a cleaning box 3, a first pipeline 4, a freeze dryer 5, a crushing mixer 6, a cleaning component, a leveling component, a first impurity removing component and a collecting component; the bottom plate 1 The lower side is bolted with two first support frames 2; the upper left part of the bottom plate 1 is fixed with a cleaning box 3; the lower part of the front side of the cleaning box 3 is connected with a first pipeline 4; Dryer 5; a crushing mixer 6 is fixedly connected to the right part of the upper side of the bottom plate 1, and the crushing mixer 6 is located behind the freeze dryer 5; a cleaning component is installed in the middle of the inner side of the cleaning box 3; a leveling component is installed on the upper side of the cleaning component; A first impurity-removing component is installed in the mi...

Embodiment 2

[0039] On the basis of Example 1, as Figure 1-3 , Figure 10 and Figure 12As shown, it also includes a second impurity-removing assembly, the upper part of the cleaning box 3 is installed with a second impurity-removing assembly, and the second impurity-removing assembly includes a support plate 601, a third elastic telescopic rod 602, a lever 603, a first square The cabin 604, the second pipeline 605, the water pump 606, the third pipeline 607 and the second square cabin 608; the inner wall of the cleaning box 3 is bolted with a support plate 601, and the support plate 601 is located in front of the second support frame 401; the support plate 601 Two third elastic telescopic rods 602 are fixedly connected to the rear; The middle part of the front side of the square cabin 604 is connected with a second pipeline 605; the middle part of the right side of the cleaning box 3 is fixedly connected with a water pump 606; the input end of the water pump 606 is connected with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com