Grinding device driven by auxiliary grinding roller

A grinding roller and grinding technology, applied in the field of vertical roller grinding equipment, can solve the problems of stable and reliable operation of unfavorable equipment, low working pressure of auxiliary grinding rollers, and large fluctuation of material layer thickness, so as to optimize material supply and improve grinding efficiency. , Improve the efficiency of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

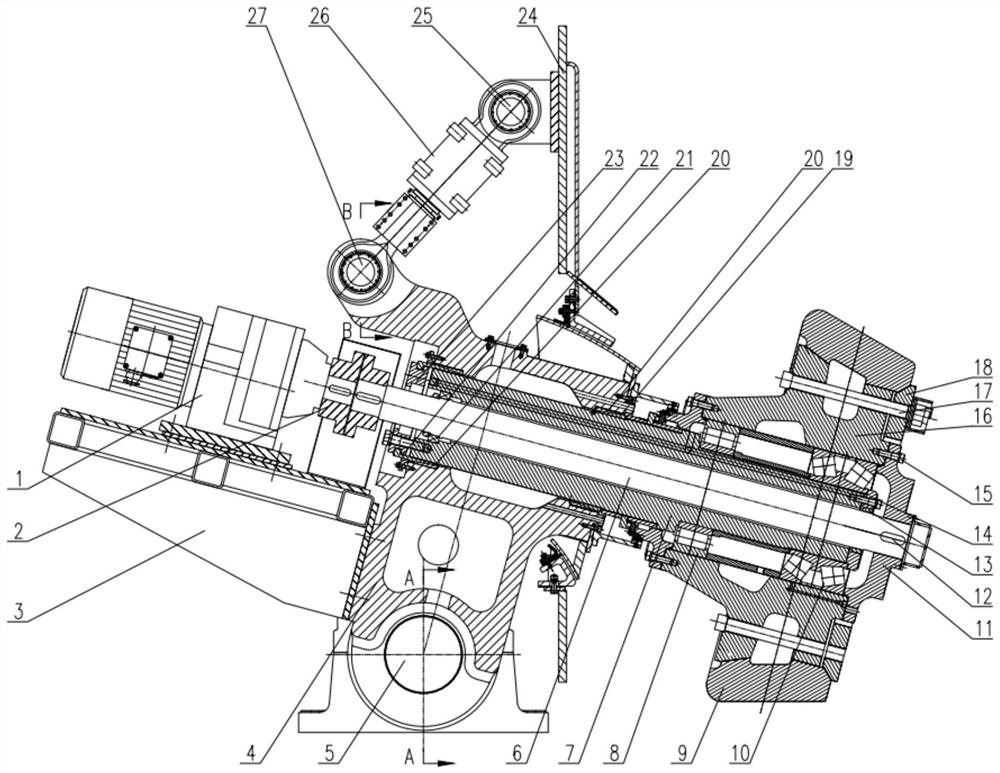

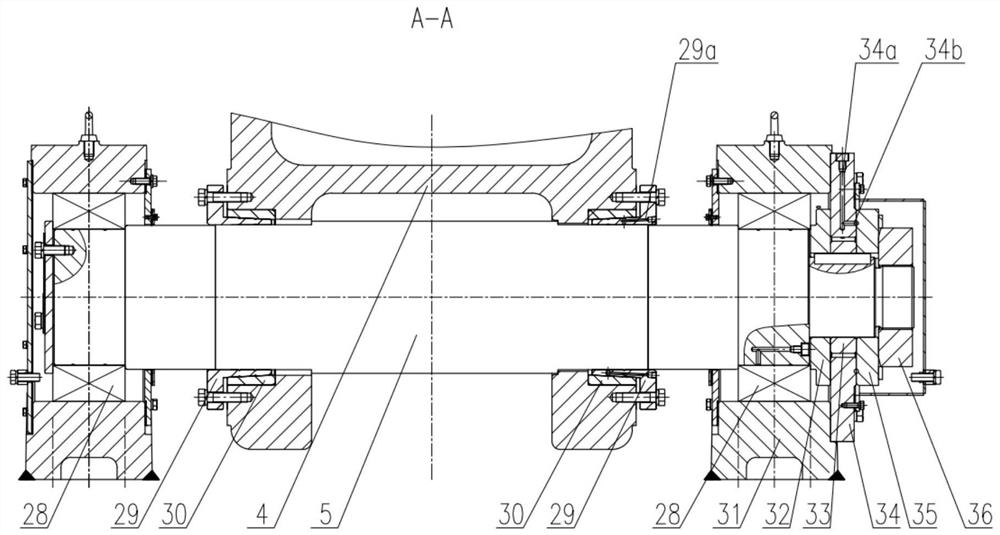

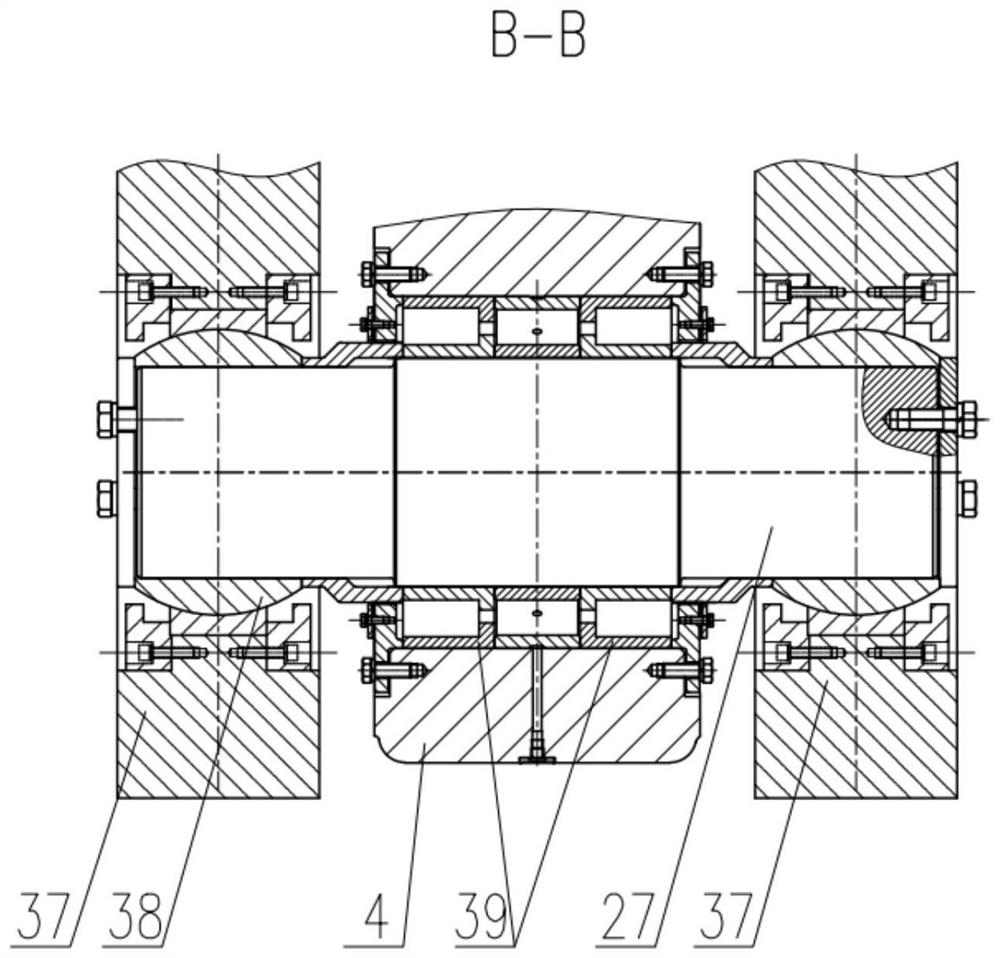

[0048] A grinding device driven by an auxiliary grinding roller includes a transmission component, an auxiliary grinding roller component, a rocker arm component, and a pressing component. The number of auxiliary grinding roller assemblies is equal to that of the main grinding rollers, and they are evenly distributed on the grinding disc and the main grinding rollers.

[0049] The main motor 48 of the vertical mill is connected to the reducer 46 through the main motor coupling 49 , the reducer 46 is connected with a grinding disc 45 , and the outer ring of the grinding disc is provided with an air duct 43 and a middle casing 40 . The main grinding roller 41 is installed in the main rocker arm 42 and fixed on the bracket 44. The connecting bridge 50 is a structural component that connects the brackets 44 for the installation of two adjacent main grinding rollers 41 into one. One end of the main roller cylinder 47 is installed on the On the bracket 44 , the other end is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com