Manufacturing process of fresh-keeping, antibacterial and fully-degradable packaging bag or packaging box

A production process and packaging bag technology, which is applied in the field of production process of fresh-keeping, antibacterial and fully degradable packaging bags or packaging boxes, can solve the problems of no preservation and bacteriostasis, long time required for degradation, poor waterproof effect, etc. To solve the problem of poor waterproof effect and oil-proof effect, excellent degradation performance and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

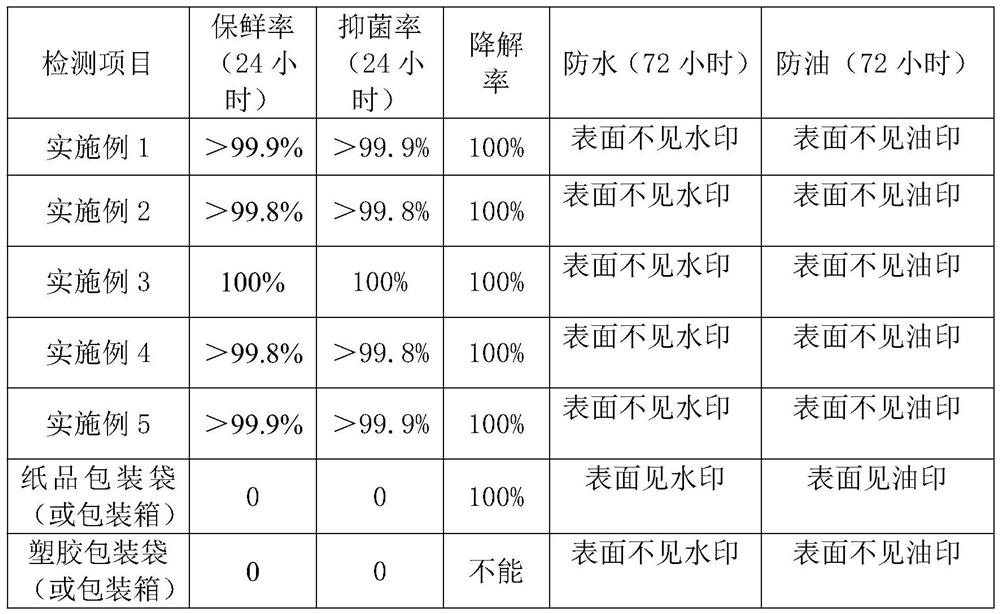

Examples

Embodiment 1

[0022] A production process of a fresh-keeping, antibacterial, fully degradable packaging bag or packaging box: the production process of the fresh-keeping, antibacterial, fully degradable packaging bag or packaging box is:

[0023] Step 1: Prepare raw materials for making packaging bags or boxes and have the functions of preservation, antibacterial, waterproof and oil-proof. The production method of the raw materials is: a. Make a mixed slurry, and the mixed slurry is based on the weight of the following components Number of servings: 10% fresh-keeping powder, 80% water and 10% dispersant.

[0024] b. Put the fresh-keeping powder and water in the above-mentioned parts by weight into the mixer. After the fresh-keeping powder and water are evenly stirred, the redispersing agent is put into the mixer. into a mixed slurry.

[0025] c. Put the mixed slurry with a component weight of 25%, a waterproof oil with a component weight of 55% and a waterproof wax with a component weight ...

Embodiment 2

[0030] A production process of a fresh-keeping, antibacterial, fully degradable packaging bag or packaging box: the production process of the fresh-keeping, antibacterial, fully degradable packaging bag or packaging box is:

[0031] Step 1: Prepare raw materials for making packaging bags or boxes and have the functions of preservation, antibacterial, waterproof and oil-proof. The production method of the raw materials is: a. Make a mixed slurry, and the mixed slurry is based on the weight of the following components Number of servings: 13% fresh-keeping powder, 79% water and 8% dispersant.

[0032] b. Put the fresh-keeping powder and water in the above-mentioned parts by weight into the mixer. After the fresh-keeping powder and water are evenly stirred, the redispersing agent is put into the mixer. into a mixed slurry.

[0033] c. Put the mixed slurry with a component weight of 28%, a waterproof oil with a component weight of 57% and a waterproof wax with a component weight o...

Embodiment 3

[0038] A production process of a fresh-keeping, antibacterial, fully degradable packaging bag or packaging box: the production process of the fresh-keeping, antibacterial, fully degradable packaging bag or packaging box is:

[0039] Step 1: Prepare raw materials for making packaging bags or boxes and have the functions of preservation, antibacterial, waterproof and oil-proof. The production method of the raw materials is: a. Make a mixed slurry, and the mixed slurry is based on the weight of the following components Number of servings: 8% of fresh-keeping powder, 86% of water and 6% of dispersant.

[0040] b. Put the fresh-keeping powder and water in the above-mentioned parts by weight into the mixer. After the fresh-keeping powder and water are evenly stirred, the redispersing agent is put into the mixer. into a mixed slurry.

[0041] c. Put the mixed slurry with a component weight of 23%, a waterproof oil with a component weight of 56% and a waterproof wax with a component ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com