Application of porous polymer film with regular pores to preparation of artificial periosteum

A technology of porous polymer and artificial bone, applied in the field of polymer materials, can solve the problem of difficult application of mechanical properties of porous polymer films, and achieve the effect of well assembled hard segments and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

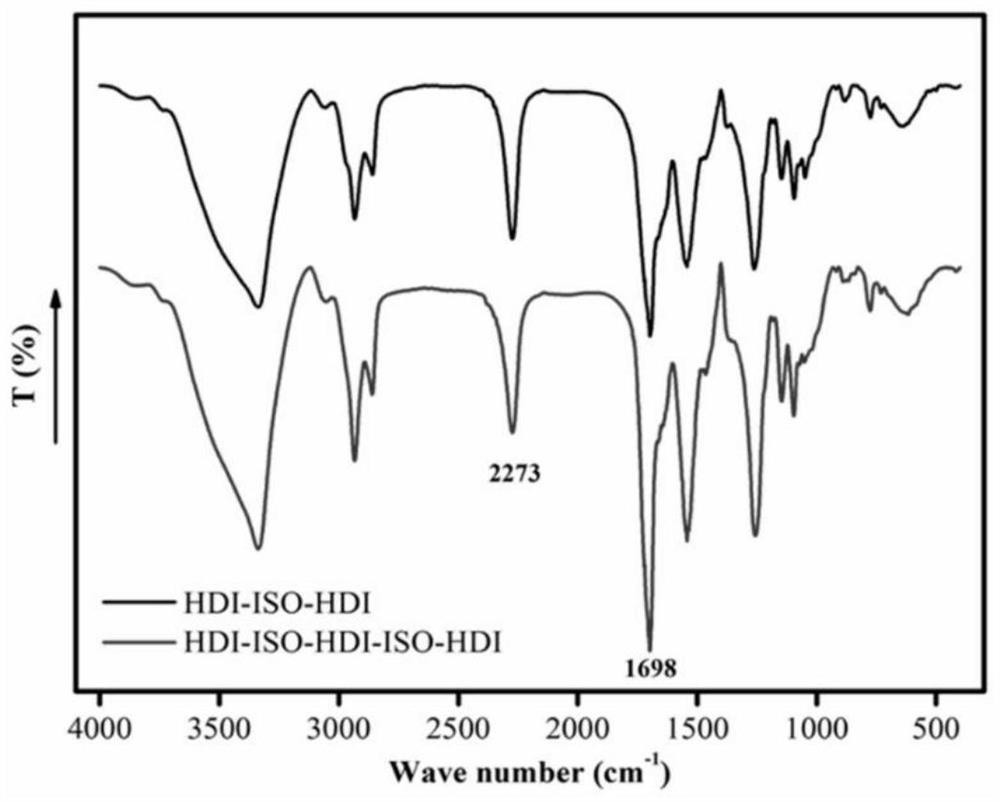

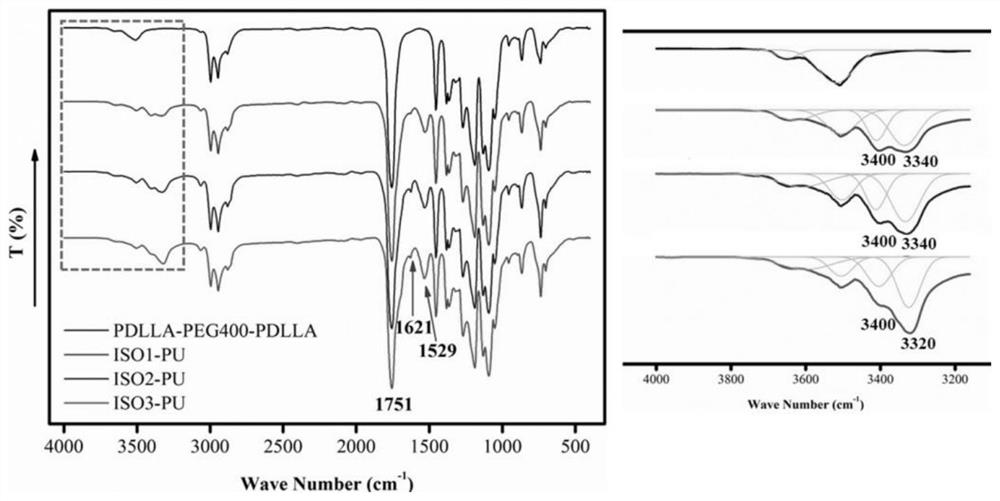

[0055] Example 1 Shape memory polyurethane

[0056] This embodiment provides a shape memory polyurethane material. Its preparation method is as follows:

[0057] 1. Synthesis and purification of PDLLA-PEG400-PDLLA macrodiol

[0058]

[0059] D,L-Lactide (D,L-Lactide, melting point: 118°C, purity: 99.9%), PEG400 (Aladdin, CAS No.: 25322-68-3, Product No.: P103723), Sn(Oct) 2 (Sigma-Aldrich, CAS No.: 301-10-0, Item No.: S3252) was added to a round-bottomed flask with a magnetic stirrer in a molar ratio of 5000:100:1, vacuumed for 30 minutes, and then sealed; the single-necked flask was placed in In an oil bath at 140°C, after the mixture was completely melted, the magnetic stirring was turned on to stir the reaction system evenly, and the reaction was continued for 24 hours; after the reaction was completed, the product was purified by a co-precipitation system of dichloromethane / ice anhydrous ethanol (-15°C) for three times. Purify again with dichloromethane / glacial n-hex...

Embodiment 2

[0081] Example 2 Porous polymer film with high mechanical properties with regular pores

[0082] In this example, the shape memory polyurethane material of Example 1 is prepared into a porous polymer film with regular pores and high mechanical properties by the following method:

[0083] Weigh the ISO-PUs (ISO2-PU, M w =61kDa, PDI=1.57), dissolve completely with chloroform in the beaker, and then dilute to volume with a volumetric flask to prepare a solution of 50 mg / mL. The coverslips were washed three times with distilled water and twice with absolute ethanol and then air-dried. Place the coverslip on a horizontal laboratory table in a fume hood with an ambient temperature of 28 °C and a humidity of 70%. Use a pipette to take about 200 μL of ISO-PUs solution and spread it evenly on the surface of the coverslip. At the same time, adjust the air flow rate to volatilize. The rate is about 20 μL / min. After the solvent is completely evaporated, a porous film with a regular hex...

experiment example 1

[0096] Experimental Example 1 Structural Characterization

[0097] The samples used in this experimental example are the ISO-PUs porous polymer film prepared in Example 2, the PPZ-PU, Upy-PU and PDLLA honeycomb porous films prepared in Comparative Example 1, and the ISO-PUs non-porous control prepared in Comparative Example 2. film.

[0098] 1. Experimental method

[0099] ① Polarizing microscope test: After the porous film on the cover glass is completely dry, place the glass slide on the stage of MP41 polarizing microscope (Mingmei Optoelectronics), and observe the porous film with a high-power lens (20-50 times) in transmission mode. The morphologies under ordinary transmitted light and cross-polarized light at corresponding positions were recorded with a digital camera.

[0100] ② Scanning Electron Microscope (SEM) test: The completely dried porous film sample was removed from the cover glass, and the surface of the film was tested by SEM using a JSM-7800F scanning elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Melting range | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com