Ferrate compound Z-type heterojunction photo-anode film and preparation method and application thereof

A technology of ferrite and composites, which is applied in the direction of liquid chemical plating, coating, metal material coating technology, etc., can solve the problems of poor metal anti-corrosion effect, and achieve the effect of improving durability and high-efficiency photocathode protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

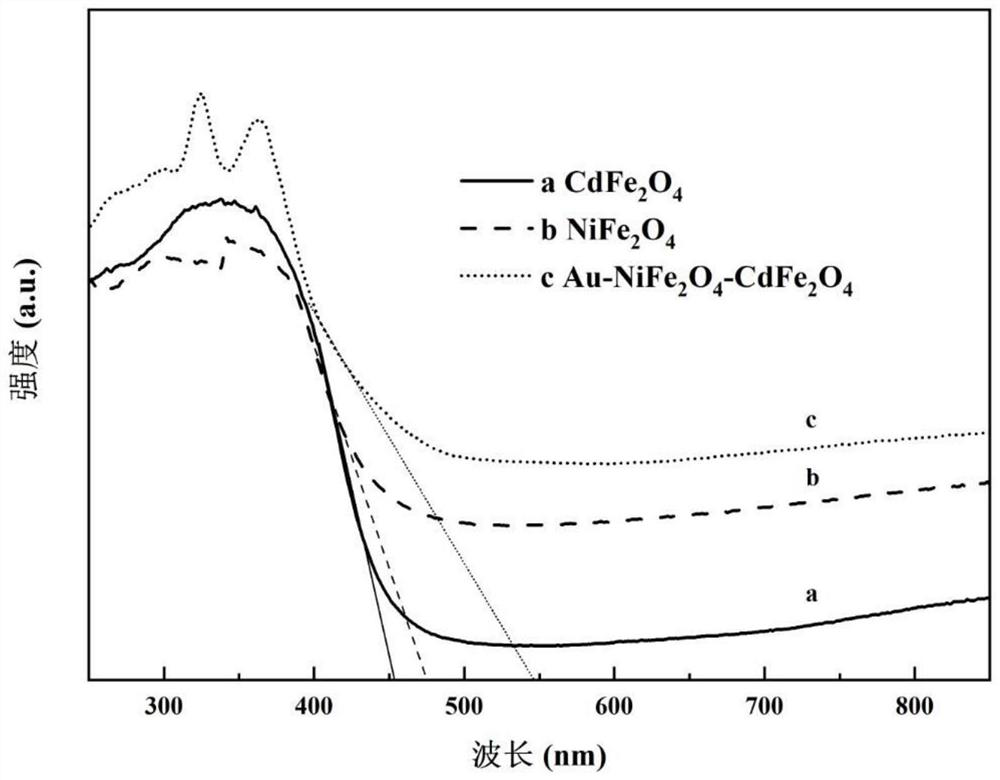

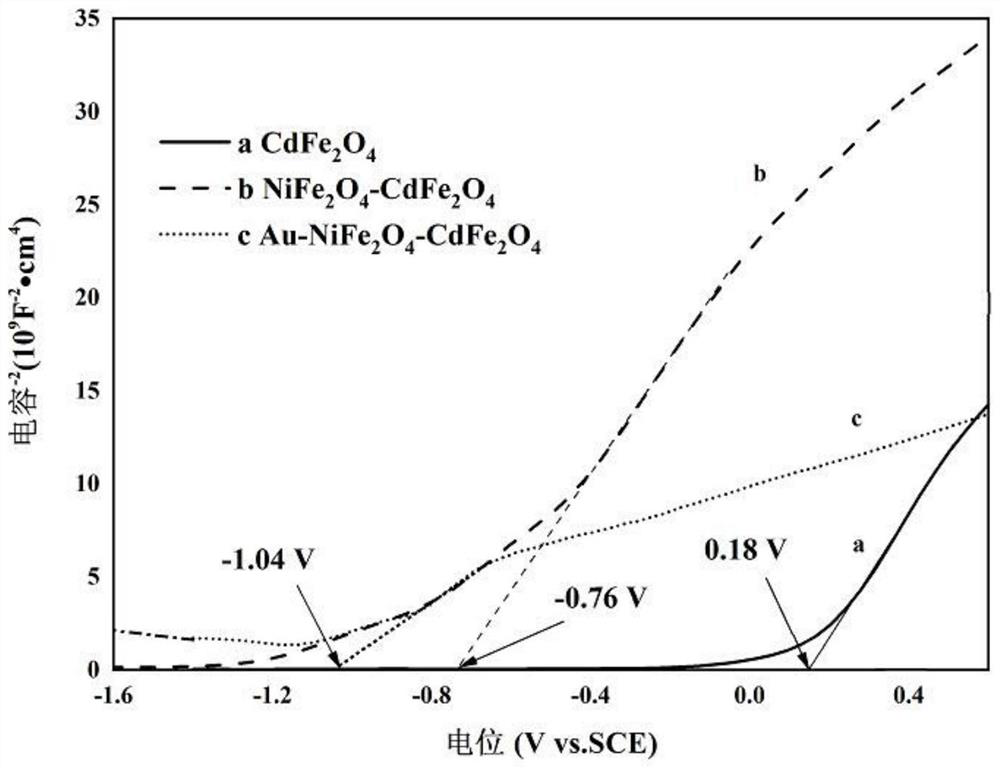

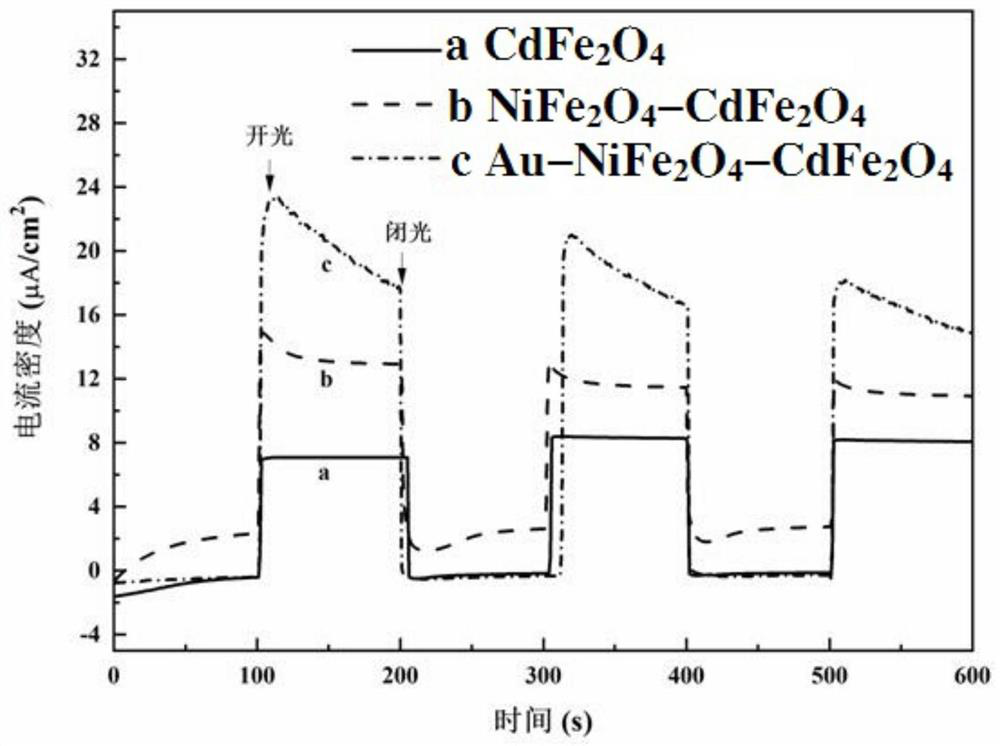

[0028] The invention provides a ferrite composite Z-type heterojunction photoanode film in view of the problem that the protection effect provided by the current type II heterojunction photocathode protection photoanode material to the concrete structural steel bar of marine construction engineering is not ideal. The preparation method of ferrite composite Z-type heterojunction photoanode film with better photocathode protection effect: a preparation method of ferrite composite Z-type heterojunction photoanode film, including the following Steps: (1) conductive glass pretreatment; (2) NiFe is prepared on the surface of the conductive glass obtained after the pretreatment in step (1) by a one-step hydrothermal method 2 O 4 -CdFe 2 O 4 layer; (3) by in situ photoreduction method on NiFe 2 O 4 -CdFe 2 O 4 An Au layer is prepared on the surface of the layer to obtain a ferrite composite Z-type heterojunction photoanode film.

[0029] This is because the NiFe in the ferrite ...

Embodiment 1

[0041] 1. The ferrite complex Z-type heterojunction photoanodic film of the present embodiment is prepared according to the following method:

[0042] (1) Conductive glass pretreatment: Before the one-step hydrothermal method, the conductive glass needs to be thoroughly cleaned to improve the bonding strength between the photoanode film and the conductive glass. First, the conductive glass was placed in a beaker containing detergent-containing aqueous solution, NaOH ethanol solution, ethanol and deionized water in sequence, and ultrasonically cleaned for 10 minutes, rinsed with deionized water, and dried at 60°C for use.

[0043] (2) Preparation of NiFe on the surface of conductive glass by one-step hydrothermal method 2 O 4 -CdFe 2 O 4 Layer: prepare a solution containing nickel chloride (final concentration of 1 mmol / L), cadmium chloride (final concentration of 100 mmol / L) and potassium ferrite (final concentration of 202 mmol / L), namely control c(Ni+Cd ): c(Fe)=1:2, sti...

Embodiment 2

[0050]1. The ferrite complex Z-type heterojunction photoanodic film of the present embodiment is prepared according to the following method:

[0051] (1) Conductive glass pretreatment: Before the one-step hydrothermal method, the conductive glass needs to be thoroughly cleaned to improve the bonding strength between the photoanode film and the conductive glass. First, the conductive glass was placed in a beaker containing detergent-containing aqueous solution, NaOH ethanol solution, ethanol and deionized water in sequence, and ultrasonically cleaned for 30 minutes, rinsed with deionized water, and dried at 40°C for use.

[0052] (2) Preparation of NiFe on the surface of conductive glass by one-step hydrothermal method 2 O 4 -CdFe 2 O 4 Layer: Prepare a solution containing nickel acetate (final concentration of 1 mol / L), cadmium acetate (final concentration of 500 mmol / L) and ammonium ferrite (final concentration of 3 mol / L), namely control c(Ni+Cd): c(Fe)=1:2, stir it even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com