A kind of photoanode material, sol-gel combustion preparation method and application

A photoanode, sol technology, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., can solve problems such as poor metal anticorrosion effect, achieve good cathodic protection effect, improve durability, and high-efficiency photocathode protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

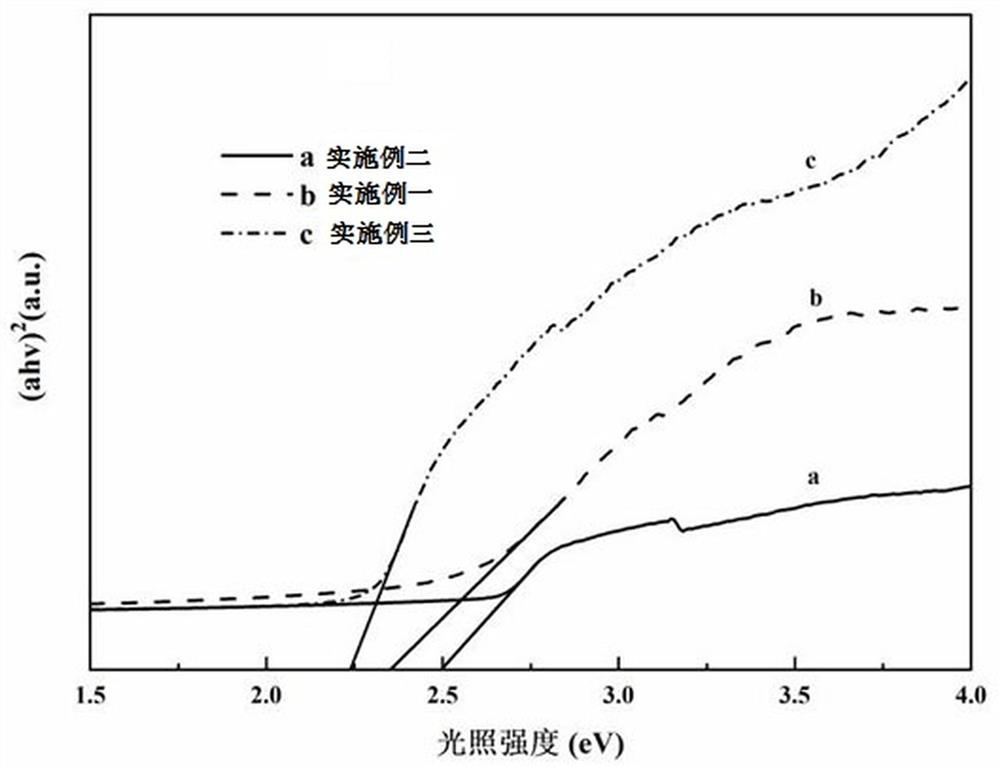

Embodiment 1

[0042] 1. The photoanode material of the present embodiment is prepared according to the following method:

[0043] (1) Prepare 100mmol / L cobalt nitrate, and then slowly add an appropriate amount of citric acid, adjust the pH of the solution to 2.5, and stir for 4h.

[0044] (2) To step (1) the resulting mixed solution was successively added butyl titanate (final concentration of 80mmol / L) and ammonium molybdate (final concentration of 20mmol / L), constant temperature 60 °C stirred for 10h.

[0045] (3) The mixed solution obtained in step (2) is dried at 140 °C to make a dry gel precursor.

[0046] (4) The dry gel precursor obtained in step (3) was roasted at 450 °C for 12h, removed, and ground evenly, that is, the photoanodic material CoMoO of the present embodiment was obtained 4 -CoTiO 3 。

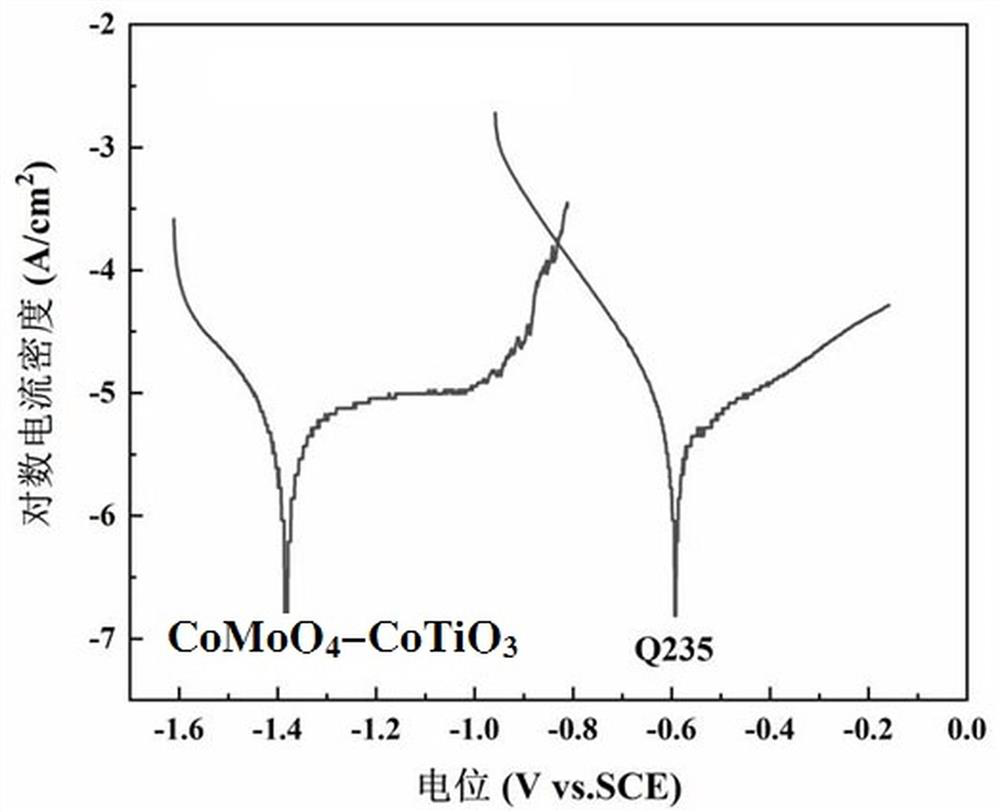

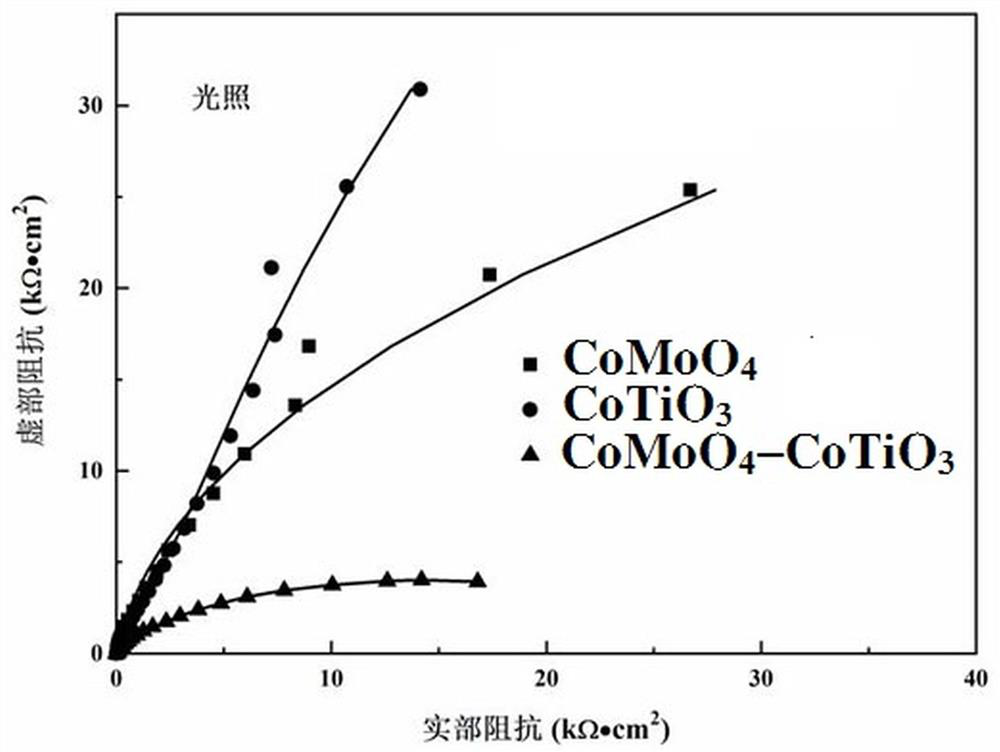

[0047] 2. Under simulated sunlight irradiation, the potentiometric polarization curve (with SCE as the reference electrode, scanning speed of 5mV / S) is judged by testing the photoanode m...

Embodiment 2

[0050] 1. The photoanode material of the present embodiment is prepared according to the following method:

[0051] (1) Prepare 10mmol / L cobalt nitrate, and then slowly add an appropriate amount of glacial acetic acid, adjust the pH of the solution to 5.5, and stir for 1h.

[0052] (2) To step (1) the resulting mixed solution was added sequentially 1mmol / L butyl titanate and 9mmol / L ammonium molybdate, stirred at a constant temperature of 20 °C for 1h.

[0053] (3) The mixed solution obtained in step (2) is dried at 140 °C to make a dry gel precursor.

[0054] (4) The dry gel precursor obtained in step (3) was roasted at 450 °C for 12h, removed, and ground evenly, that is, the photoanodic material CoMoO of the present embodiment was obtained 4 -CoTiO 3 。

[0055] 2, the Present Embodiment of CoMoO 4 The photoanode material is prepared according to the following method: CoMoO with the above-described photoanode material 4 -CoTiO 3 Compared with the preparation method, only the step...

Embodiment 3

[0060] The photoanode material of the present embodiment is prepared according to the following method:

[0061] (1) Prepare 50mmol / L cobalt nitrate, then slowly add an appropriate amount of citric acid, adjust the pH of the solution to 3.5, and stir for 2h.

[0062] (2) To step (1) the resulting mixed solution was successively added 35mmol / L butyl titanate and 15mmol / L sodium molybdate, constant temperature 40 °C stirred for 1h.

[0063] (3) Place the resulting mixed solution in step (2) at 100 °C to dry and make a dry gel precursor.

[0064] (4) The dry gel precursor obtained in step (3) was roasted at 850 ° C for 6h, removed, and ground evenly, that is, the photoanodode material CoMoO of the present embodiment was obtained 4 -CoTiO 3 。

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com