Cathode protection Z-type photo-anode material, ion layer deposition preparation method and application

A cathodic protection and photoanode technology, which is applied in the field of metal corrosion inhibition in marine construction projects, can solve the problems of poor metal corrosion resistance and achieve the effects of improving durability, improving redox performance, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Aiming at the problem of poor anticorrosion effect on metals used in marine construction projects that exists in the photoanode materials currently used for photocathode protection, the present invention provides a method for preparing an ion layer deposition of a cathodic protection Z-type photoanode material: comprising the following steps: Steps: (1) conductive glass pretreatment; (2) ion layer deposition on the surface of the conductive glass obtained by step (1) pretreatment to obtain Ce 2 S 3 layer; (3) in Ce 2 S 3 Bi-layer surface ion layer deposition 2 S3 Floor.

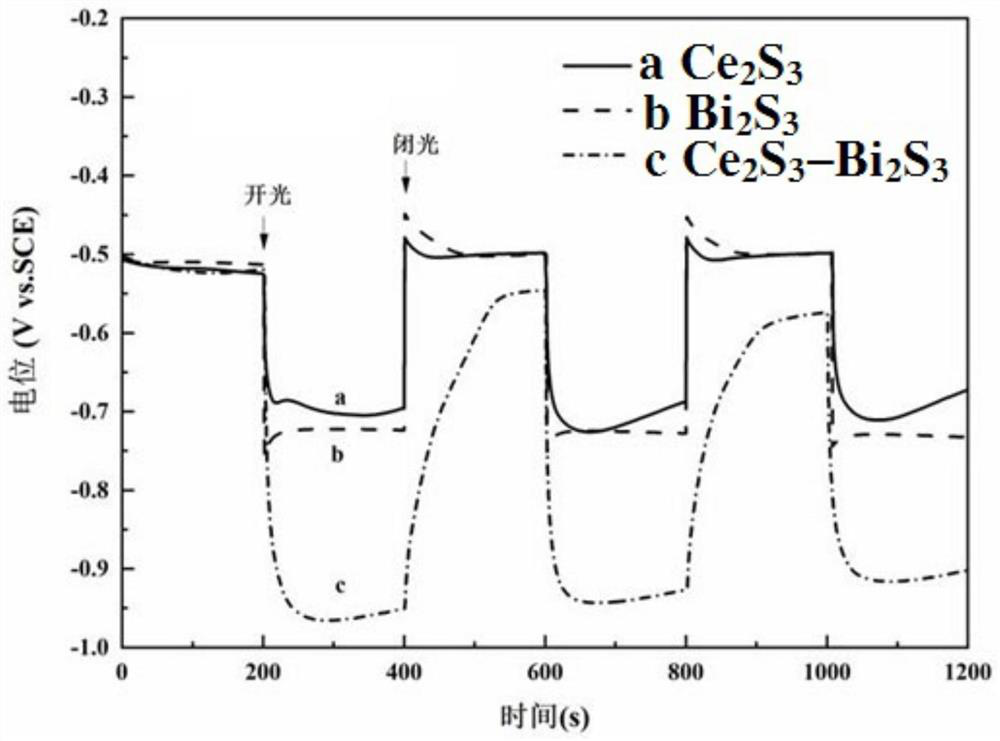

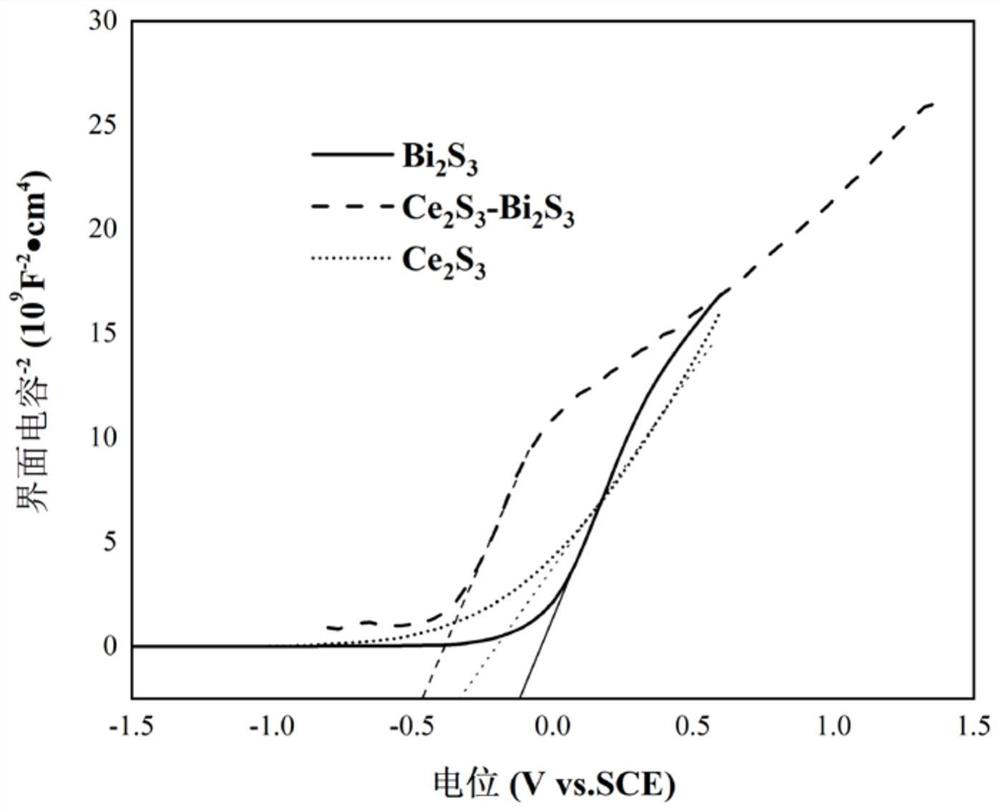

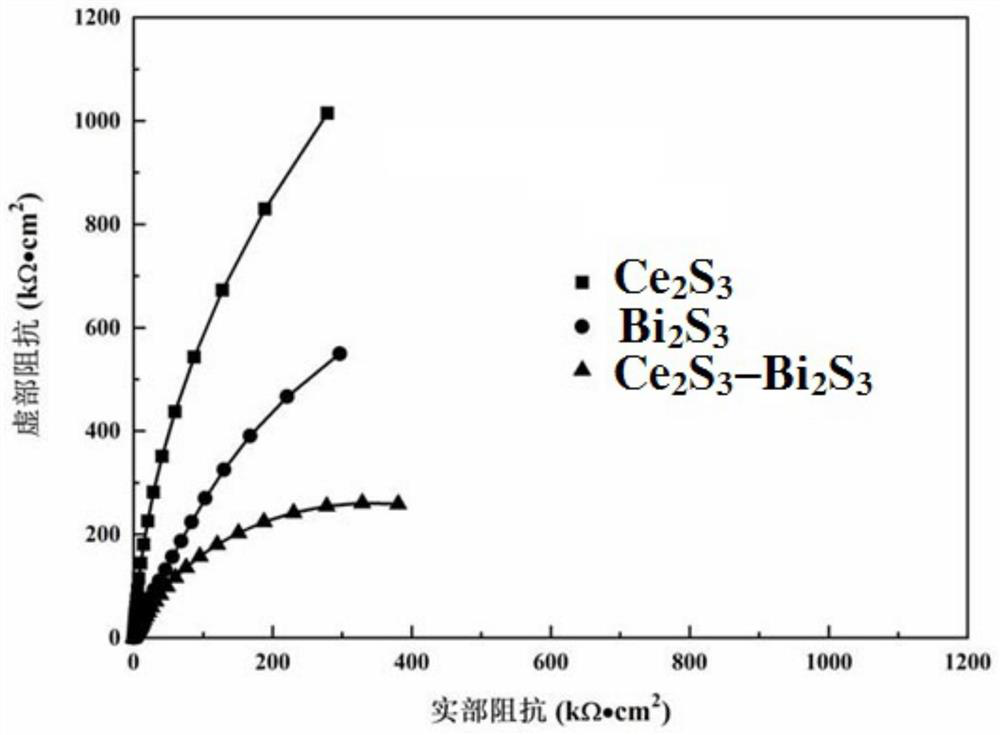

[0029] Due to Ce 2 S 3 with Bi 2 S 3 With a matching band structure, Ce 2 S 3 has a lower conduction band potential (-0.91Vvs.NHE), while Bi 2 S 3 Has a higher valence band potential (1.38V vs. NHE), while Bi 2 S 3 The conduction band potential (-0.33Vvs.NHE) of Ce 2 S 3 The valence band potential (1.19V vs. NHE) is lower, Bi 2 S 3 Photogenerated electrons in the conduction band can be...

Embodiment 1

[0041] 1. The cathodic protection Z-type photoanode material of the present embodiment is prepared according to the method comprising the following steps:

[0042] (1) Conductive glass pretreatment: Thoroughly clean the conductive glass first to improve the bonding strength between the photoanode film and the conductive glass. The specific steps are as follows: First, put the conductive glass into a beaker containing detergent-containing aqueous solution, NaOH ethanol solution, ethanol and deionized water in sequence, and ultrasonically clean for 10 minutes, rinse with deionized water, and then dry at 60 °C for use. .

[0043] (2) depositing Ce on the surface of the conductive glass obtained by the treatment in step (1) 2 S 3 layer (ion layer deposition to prepare Ce 2 S 3 ): a. use the conductive glass obtained in step (1) as a substrate, soak it in a solution containing cerium nitrate (concentration of 50 mmol / L) for 30s; b. soak the obtained sample in a solution contain...

Embodiment 2

[0050] 1. The cathodic protection Z-type photoanode material of the present embodiment is prepared according to the method comprising the following steps:

[0051] (1) Conductive glass pretreatment: Thoroughly clean the conductive glass first to improve the bonding strength between the photoanode film and the conductive glass. The specific steps are as follows: First, put the conductive glass into a beaker containing detergent-containing aqueous solution, NaOH ethanol solution, ethanol and deionized water in sequence, and ultrasonically clean it for 30 minutes, rinse it with deionized water, and then dry it at 60 °C for use. .

[0052] (2) depositing Ce on the surface of the conductive glass obtained by the treatment in step (1) 2 S 3 layer (ion layer deposition to prepare Ce 2 S 3 ): a. use the conductive glass obtained in step (1) as a substrate, soak it in a solution containing cerium citrate (concentration of 1 mmol / L) for 3 min; b. soak the obtained sample in a soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com