Z-type cerium sulfide-based cathodic protection photoanode film and its preparation method and application

A cathodic protection, cerium sulfide-based technology, applied in the field of Z-type cerium sulfide-based cathodic protection photoanode film and its preparation, can solve problems such as poor metal anticorrosion effect, and achieve improved durability, improved separation efficiency, and high-efficiency photocathode protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

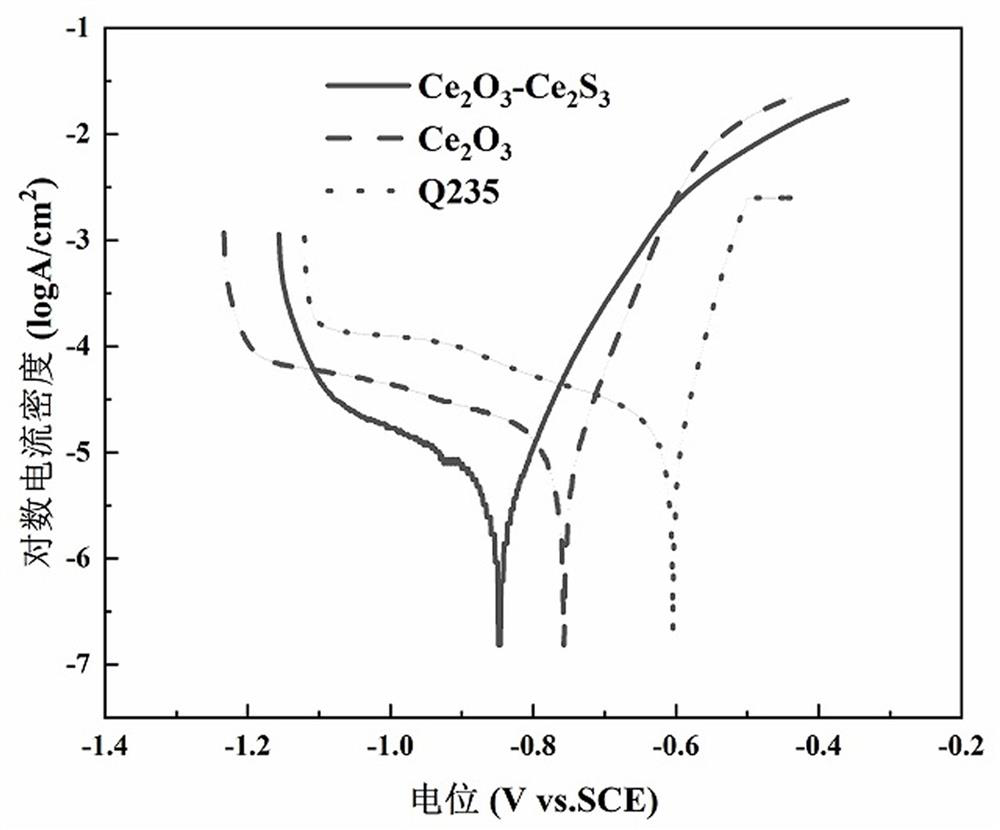

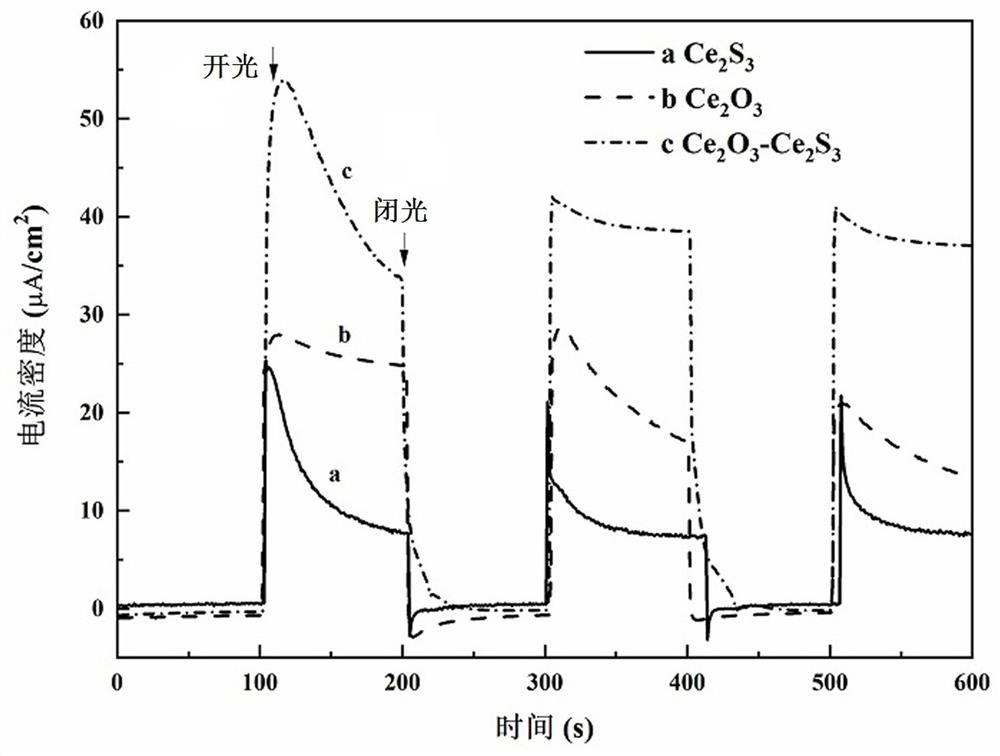

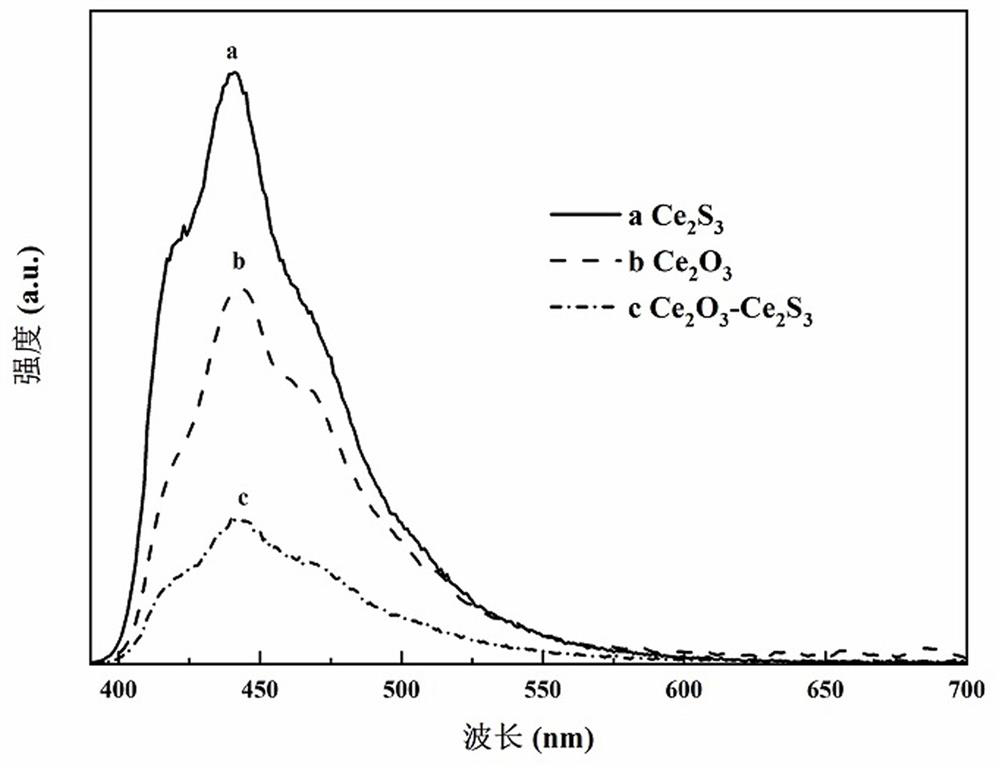

[0034] Aiming at the problem of unsatisfactory protection effect when type II heterojunction is currently used for cathodic protection of steel bars in marine structures, the present invention proposes a Z-type Ce for marine construction engineering metal anticorrosion. 2 O 3 -Ce 2 S 3 The preparation method of the composite photoanode film mainly includes the following steps: (1) pretreating the conductive glass; (2) preparing Ce by hydrothermal method 2 O 3 Photoanode film; (3) Partial vulcanization at high temperature to prepare Ce 2 O 3 -Ce 2 S 3 Composite photoanodic film.

[0035] Ce for marine construction engineering metal anticorrosion of the present invention 2 O 3 -Ce 2 S 3 The preparation of composite photoanode film is formed on the surface of conductive glass by hydrothermal method and high temperature partial vulcanization. The heterojunction is in Z-type electron transport mode, which can significantly improve the redox property of the composite film...

Embodiment 1

[0052] The preparation method of a Z-type cerium sulfide-based cathodic protection photoanode film provided by this embodiment includes the following steps:

[0053] (1) Conductive glass pretreatment: Before the one-step hydrothermal method, the conductive glass needs to be thoroughly cleaned to improve the bonding strength between the photoanodic film and the conductive glass. First, the conductive glass was placed in a beaker containing detergent-containing aqueous solution, NaOH ethanol solution, ethanol and deionized water in sequence, and ultrasonically cleaned for 10 minutes, rinsed with deionized water, and dried at 60°C for use.

[0054] (2) Preparation of Ce by hydrothermal method 2 O 3 : Put 0.01mol / L cerium nitrate into a beaker, add NaOH solution to adjust pH=9.5, stir evenly, put it into the reaction kettle, put the conductive side of the electrode in step (1) into the above solution, control the water The heating temperature is 210°C and the reaction time is 24...

Embodiment 2

[0058] The preparation method of a Z-type cerium sulfide-based cathodic protection photoanode film provided by this embodiment includes the following steps:

[0059] (1) Conductive glass pretreatment: Before the one-step hydrothermal method, the conductive glass needs to be thoroughly cleaned to improve the bonding strength between the photoanode film and the conductive glass. First, the conductive glass was placed in a beaker containing detergent-containing aqueous solution, NaOH ethanol solution, ethanol and deionized water in sequence, and ultrasonically cleaned for 30 minutes, rinsed with deionized water, and dried at 60°C for use.

[0060] (2) Preparation of Ce by hydrothermal method 2 O 3 : Put 1mol / L cerium acetate into a beaker, add potassium hydroxide to adjust pH=7.5, stir evenly, put it into the reaction kettle, put the conductive side of the electrode in step (1) into the above solution, control the water The heating temperature is 130°C and the reaction time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com