Near back scattering type vehicle-mounted particulate matter sensor and exhaust pipe

A particle sensor and backscattering technology, which can be used in exhaust devices, particle suspension analysis, scientific instruments, etc., can solve the problems of difficult removal of mirror pollution, exhaust pollution of reflective mirrors, and reduced laser transmission efficiency, so as to achieve accurate measurement and improve Monotonous responsiveness, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

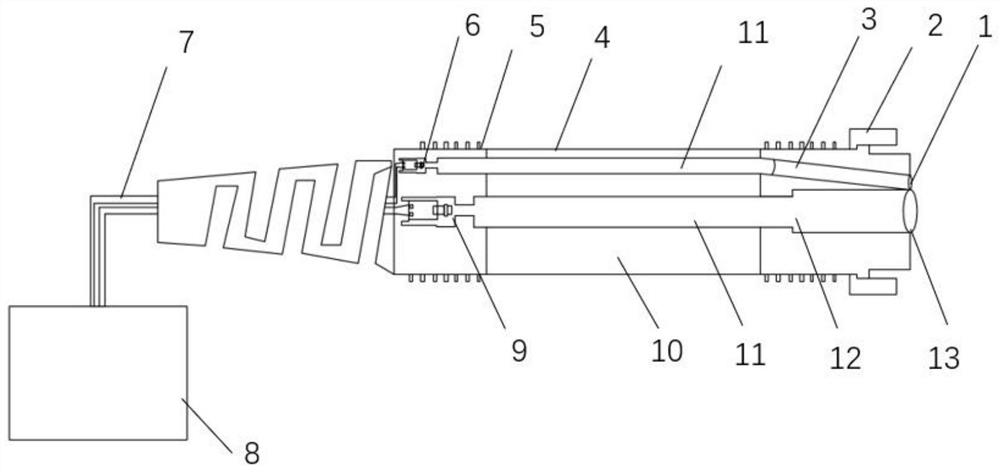

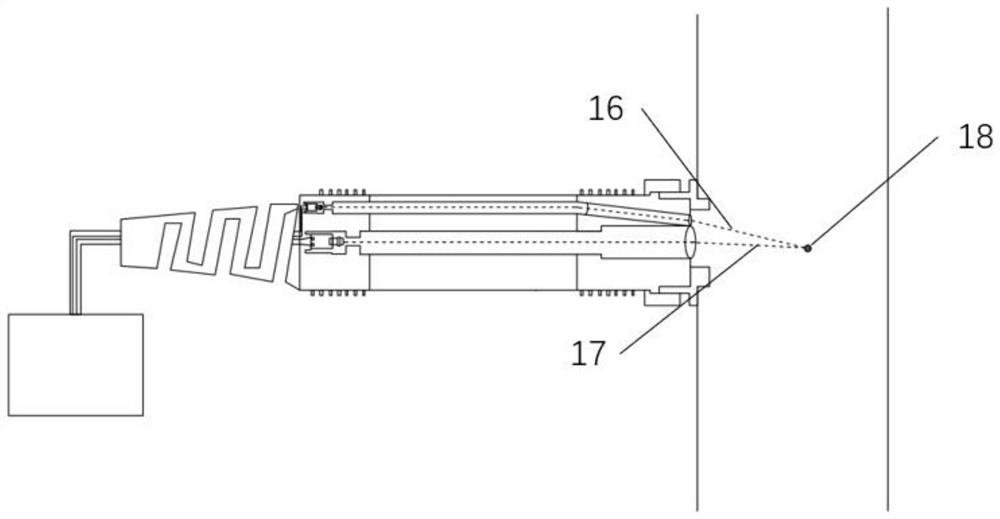

[0052] like figure 1 and 2 As shown, the near-backscattering vehicle-mounted particle sensor includes a collimating lens 1, a tightening nut 2, a laser channel 3, a probe rod body 4, a heat dissipation fin 5, a laser 6, a wire harness 7, a controller 8, a detector 9, Thermal insulation column 10, optical fiber 11, photosensitive channel 12, condenser lens 13 and exhaust pipe 15;

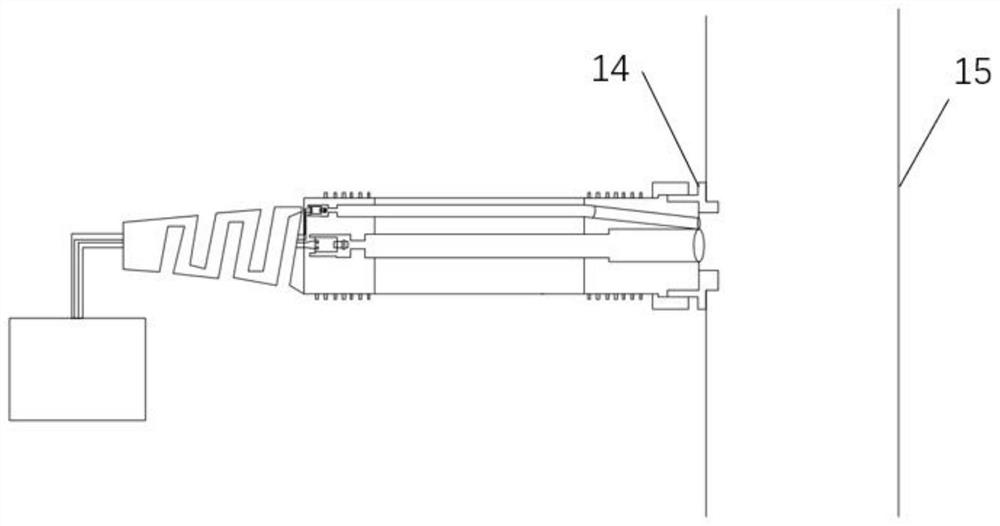

[0053] It should be noted that the probe base 14 is mounted on the exhaust pipe. The optical fiber 11 between the laser channel 3 and the laser 6 is the first optical fiber; the optical fiber 11 between the photosensitive channel 12 and the detector 9 is the second optical fiber.

[0054] The inside of the probe rod body 4 is equipped with the laser 6, the collimating lens 1, the condenser lens 13 and the detector 9; the laser 6 and the detector 9 are located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com