High-speed steel tool steel and tungsten steel efficient heating fusion method

A fusion method and tool steel technology, applied in the direction of manufacturing tools, metal processing equipment, auxiliary welding equipment, etc., can solve the problems affecting the performance of high-speed steel tool steel, complex preparation process, poor performance of connecting parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

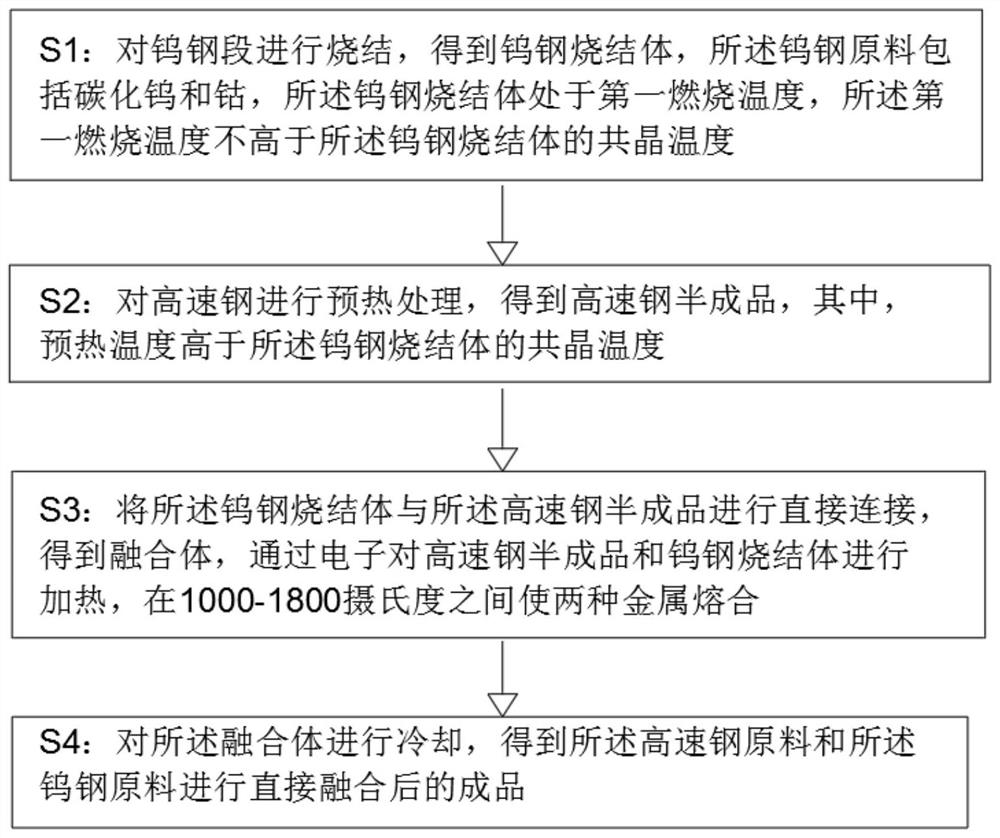

[0022] refer to figure 1 , a high-efficiency heating fusion method of high-speed steel tool steel and tungsten steel, which specifically includes the following steps:

[0023] S1: sintering the tungsten steel section to obtain a tungsten steel sintered body, the tungsten steel raw material includes tungsten carbide and cobalt, the tungsten steel sintered body is at a first combustion temperature, and the first combustion temperature is not higher than the tungsten steel sintered body The eutectic temperature of the steel sintered body;

[0024] S2: preheating the high-speed steel tool steel to obtain a semi-finished product of the high-speed steel tool steel, wherein the preheating temperature is higher than the eutectic temperature of the tungsten steel sintered body;

[0025] S3: Directly connect the tungsten steel sintered body and the high-speed steel tool steel semi-finished product to obtain a fusion body, and electronically heat the high-speed steel tool steel semi-fin...

Embodiment 2

[0035] A high-speed steel tool steel and tungsten steel high-efficiency heating fusion method, which specifically includes the following steps:

[0036] S1: sintering the tungsten steel section and the high-speed steel tool steel to obtain a tungsten steel sintered body and a semi-finished high-speed steel tool steel mixture;

[0037] S2: the mixture of the tungsten steel sintered body and the high-speed steel tool steel semi-finished product is heated by electronically heating the high-speed steel tool steel semi-finished product and the tungsten steel sintered body, and the two metals are fused between 1000-1800 degrees Celsius;

[0038] S3: cooling the fusion body to obtain a finished product obtained by direct fusion of the high-speed steel tool steel raw material and the tungsten steel raw material;

[0039] After directly heating the high-speed steel tool steel and tungsten steel, the obtained mixture is not as good as the fusion body obtained in Example 1.

Embodiment 3

[0041] A high-speed steel tool steel and tungsten steel high-efficiency heating fusion method, which specifically includes the following steps:

[0042] S1: sintering the tungsten steel section to obtain a tungsten steel sintered body, the tungsten steel raw material includes tungsten carbide and cobalt, the tungsten steel sintered body is at a first combustion temperature, and the first combustion temperature is not higher than the tungsten steel sintered body The eutectic temperature of the steel sintered body;

[0043] S2: preheating the high-speed steel tool steel to obtain a semi-finished product of the high-speed steel tool steel, wherein the preheating temperature is higher than the eutectic temperature of the tungsten steel sintered body;

[0044] S3: Directly connect the tungsten steel sintered body and the high-speed steel tool steel semi-finished product to obtain a fusion body, heat the high-speed steel tool steel semi-finished product and the tungsten steel sinter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com