Robot teaching method and system for welding trailer frame

A teaching method and robot technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of repetitive work and low automation rate, and achieve the effect of saving labor time and improving programming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

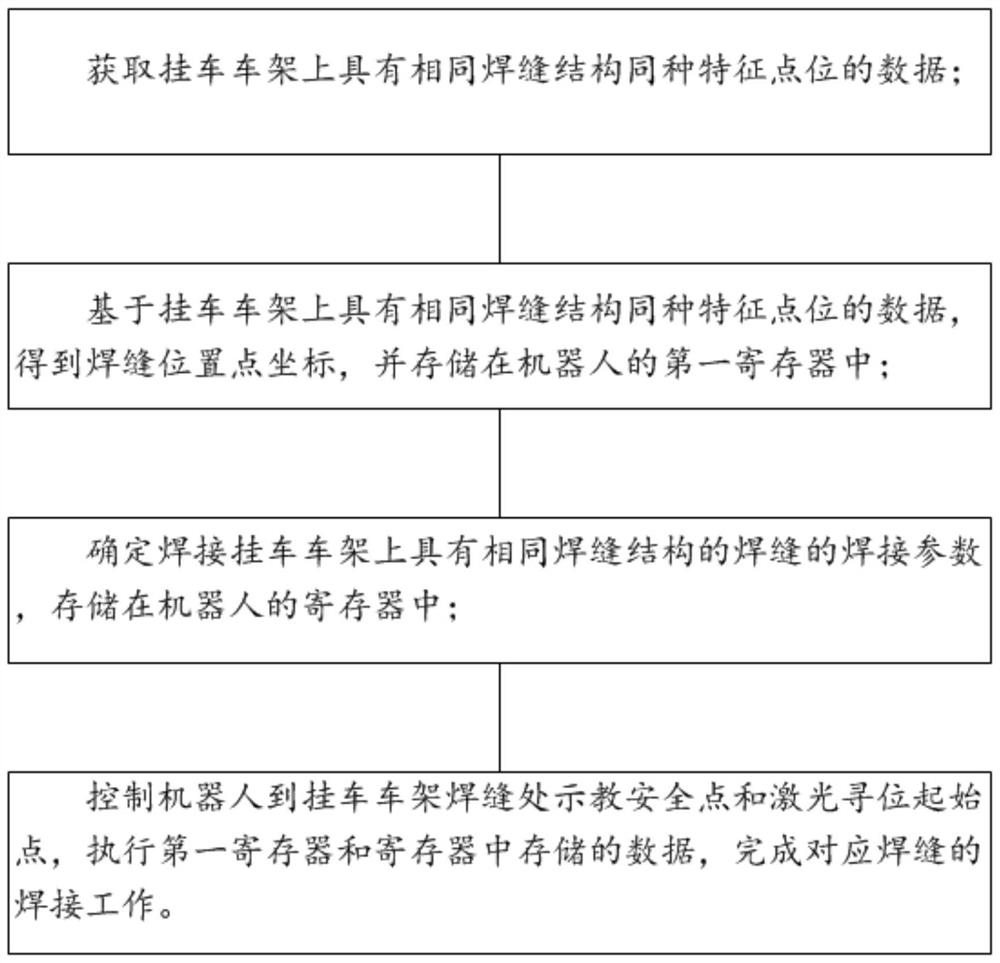

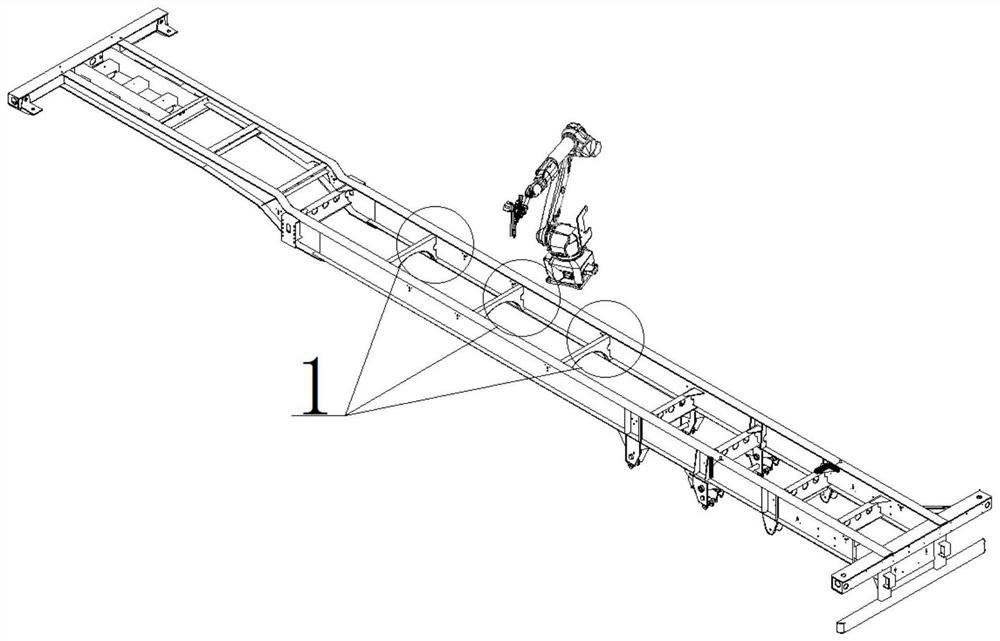

[0045] like figure 1 As shown in the figure, this embodiment provides a robot teaching method for welding a trailer frame. In this embodiment, the method is applied to a server for illustration. It can be understood that this method can also be applied to a terminal, and can also be applied to It includes terminals, servers and systems, and is realized through the interaction of terminals and servers. The server can be an independent physical server, a server cluster or a distributed system composed of multiple physical servers, or a cloud service, cloud database, cloud computing, cloud function, cloud storage, network server, cloud communication, intermediate Cloud servers for basic cloud computing services such as software services, domain name services, security service CDNs, and big data and artificial intelligence platforms. The terminal may be a smart phone, a tablet computer, a notebook computer, a desktop computer, a smart speaker, a smart watch, etc., but is not limi...

Embodiment 2

[0102] This embodiment provides a robot teaching system for welding a trailer frame.

[0103] A robot teaching method for welding a trailer frame, comprising:

[0104] a data acquisition module, which is configured to: acquire data of the same feature points with the same welding seam structure on the trailer frame;

[0105] a welding seam position point coordinate determination module, which is configured to: obtain the welding seam position point coordinates based on the data of the same characteristic points of the same welding seam structure on the trailer frame, and store them in the first register of the robot;

[0106] a welding parameter determination module, which is configured to: determine the welding parameters of the welding seam with the same welding seam structure on the frame of the welding trailer, and store the welding parameters in the register of the robot;

[0107] The control module is configured to: control the robot to teach the safety point and the st...

Embodiment 3

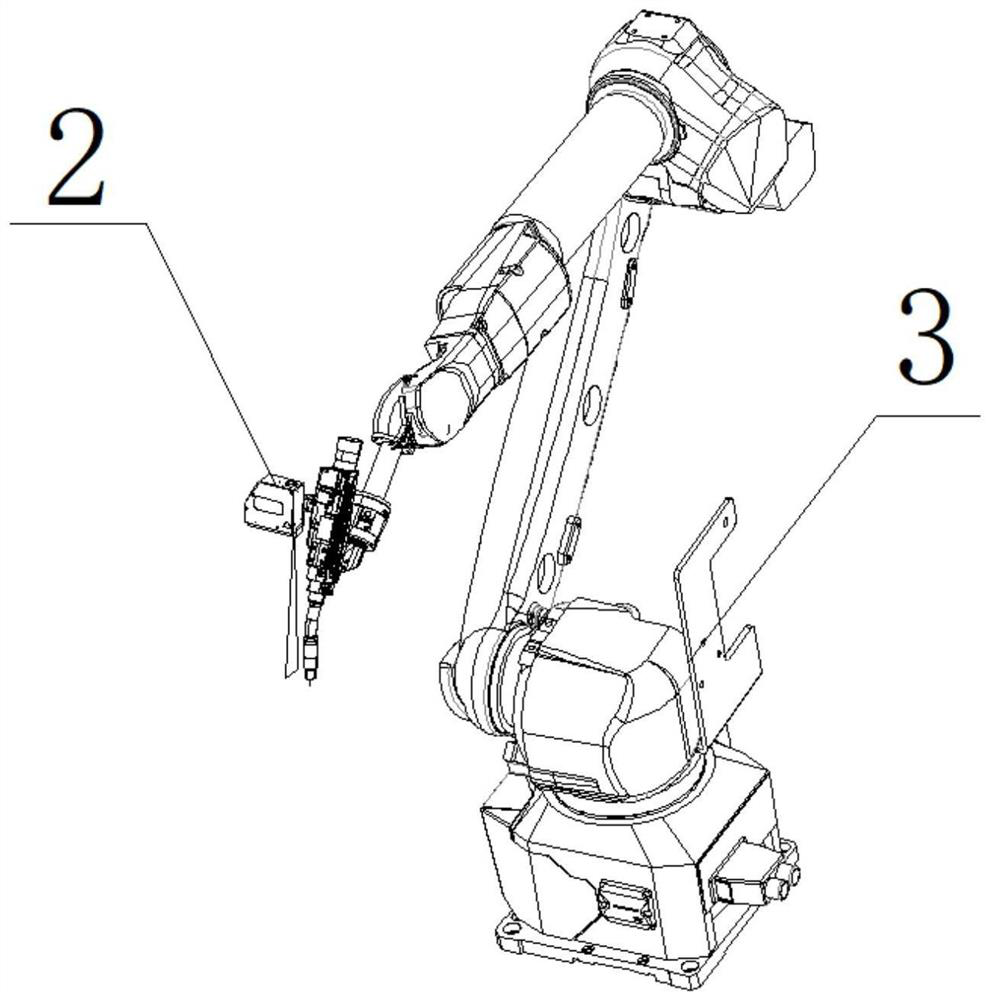

[0110] This embodiment provides a robot teaching system for welding a trailer frame.

[0111] A robot teaching system for welding a trailer frame, comprising:

[0112] The positioning device is used to obtain the data of the same characteristic points with the same welding seam structure on the trailer frame;

[0113] The processor is used to connect the positioning device, and based on the data of the same characteristic points of the same welding seam structure on the trailer frame, obtain the coordinates of the welding seam position point, and store it in the first register of the robot; determine the welding trailer frame The welding parameters of the seam with the same seam structure are stored in the register of the robot;

[0114] The robot is used to connect to the processor. When it moves to the teaching safety point and the starting point of laser positioning at the welding seam of the trailer frame, it executes the first register and the data stored in the register t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com