Complete vehicle wire harness arrangement method based on CHS topological structure

A technology of topology structure and layout method, which is applied to vehicle components, geometric CAD, instruments, etc., can solve the problem that the layout method of the vehicle wiring harness does not fully consider the platform, and achieve the effect of improving development efficiency and wiring harness cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

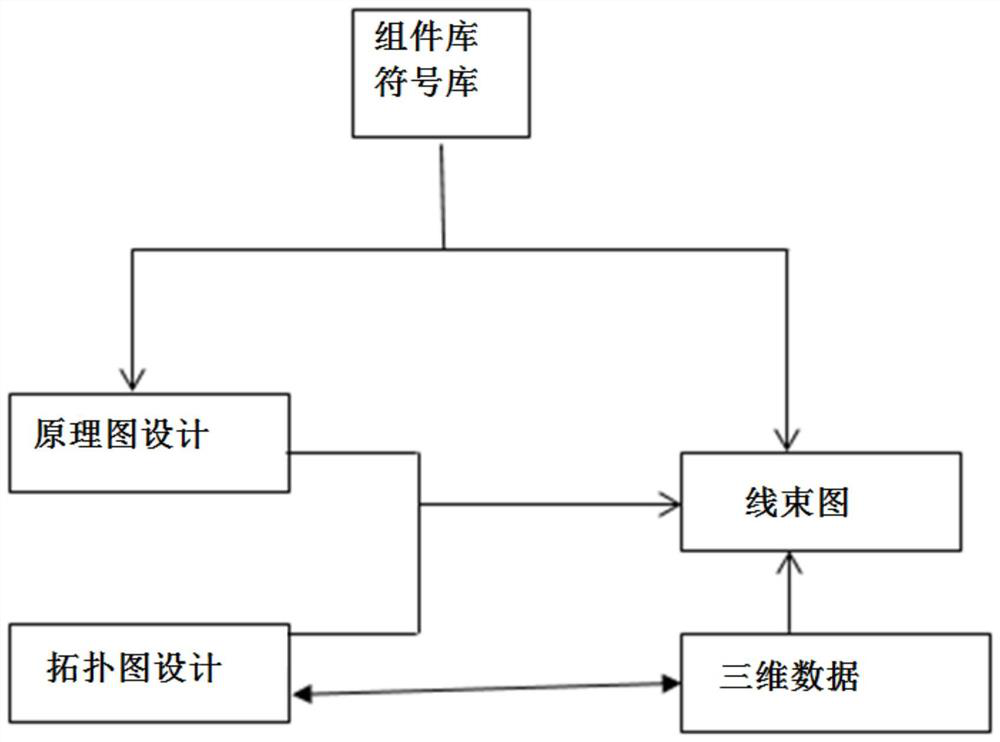

[0050] CHS is a professional wire harness design software toolkit developed by Mentor Graphics, an internationally renowned EDA manufacturer, for aviation, aerospace, vehicles and other fields. process. Our company currently mainly uses the schematic diagram tool Capital Logic, the wiring harness diagram tool Capital HarnessXC and the CATIA 3D interface in engineering projects. The design idea of CHS is data-centric, making full use of the design results of the previous stage in the design process, greatly improving the reuse of design data, and thus improving the overall design efficiency.

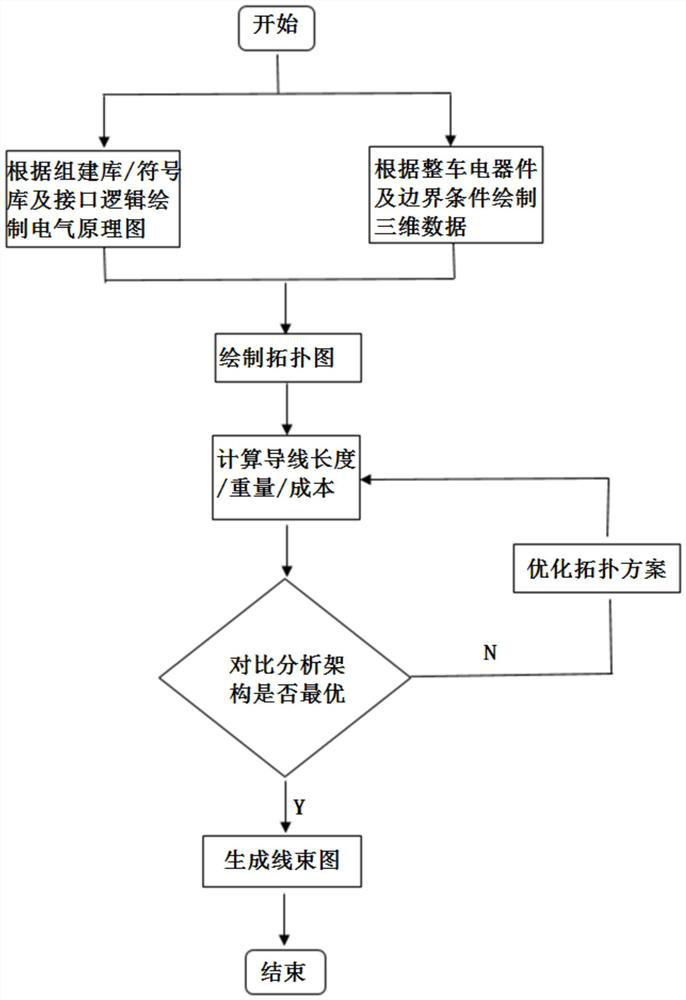

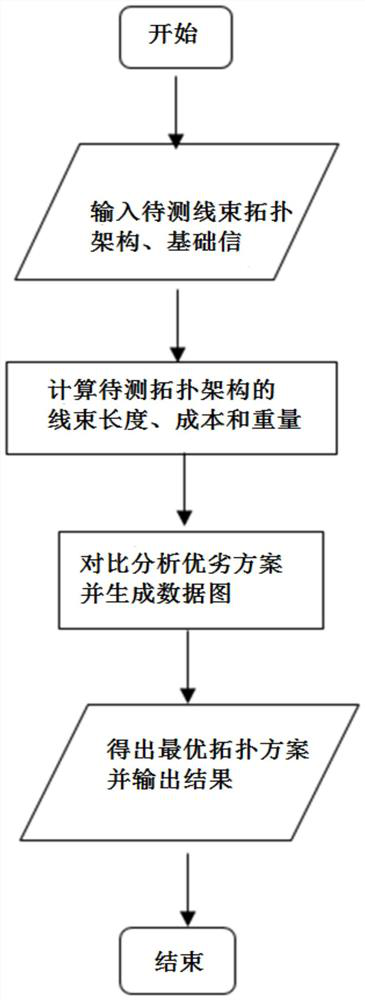

[0051] like figure 1 and figure 2 As shown, the present invention provides a method for arranging a vehicle wiring harness based on a CHS topology, including the steps of:

[0052] The first step is to draw the electrical schematic diagram of the vehicle in the logic module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com