Transferring and discharging device and method for numerical control electromechanical equipment production

A technology of electromechanical equipment and lifting devices, which is applied in the field of transfer and blanking devices for the production of numerical control electromechanical equipment, and can solve problems such as confusion of different metal parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

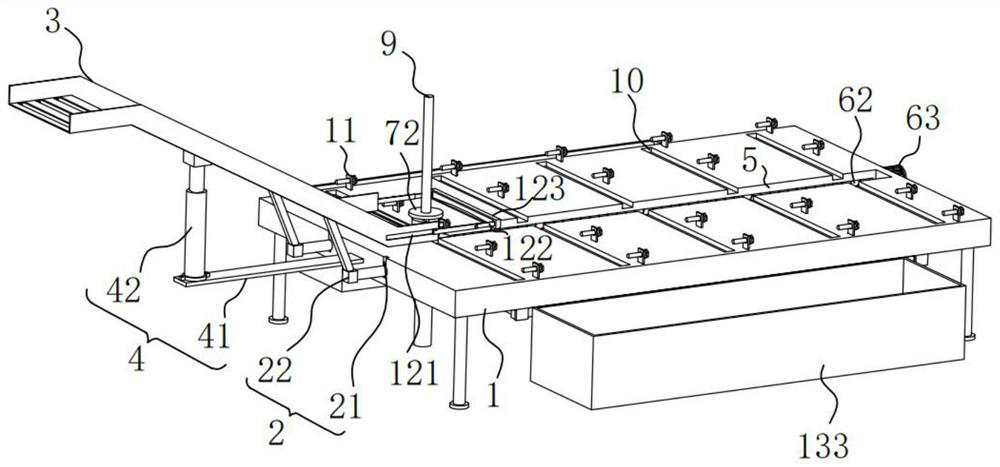

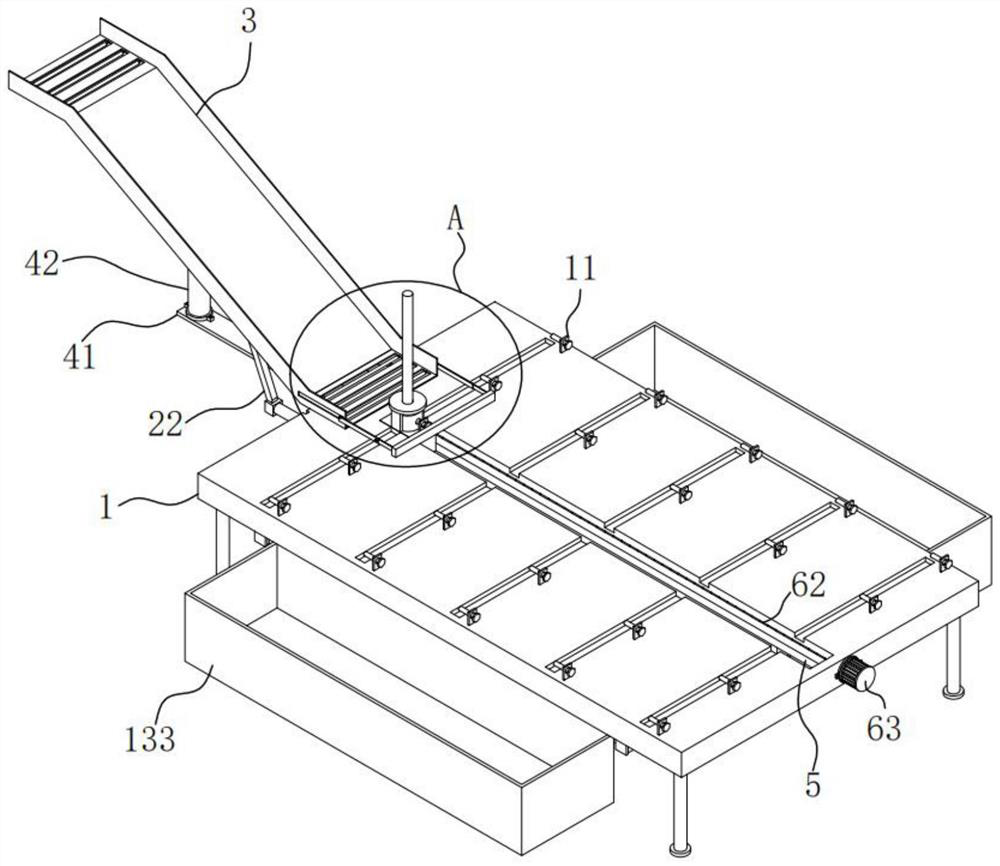

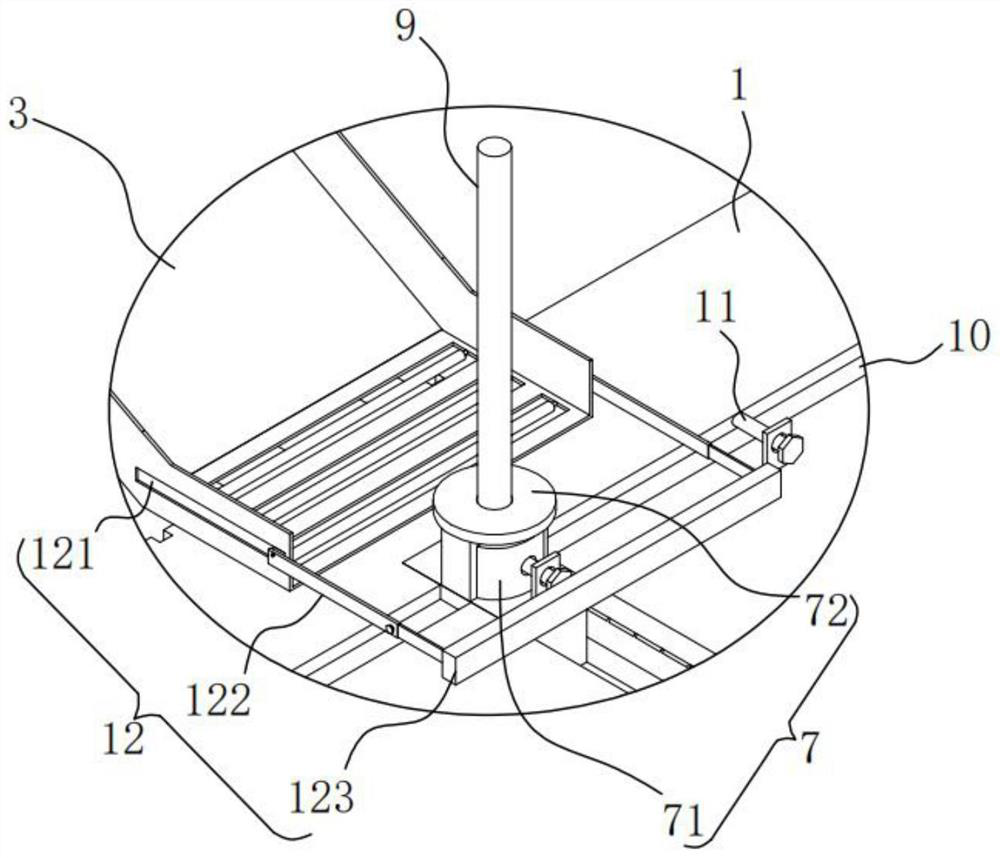

[0057] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1A schematic structural diagram of the first embodiment of a transfer and blanking device for production of numerically controlled electromechanical equipment and a method thereof provided by the present invention; figure 2 for figure 1 Shown is a schematic diagram of the isometric structure of the device as a whole; image 3 for figure 2 The enlarged schematic diagram of Part A shown; Figure 4 for figure 1 The schematic diagram of the overall structure of the device shown; Figure 5 for figure 1 The schematic diagram of the structure of the overall bottom of the device shown. A transfer and blanking device for the production of numerically controlled electromechanical equipment, comprising:

[0058] The placing table 1, a support assembly 2 is provided on one side of the surface of the placing table 1, the supporting assembly 2 includes two grooves 21, and a support fra...

no. 2 example

[0089] Please refer to figure 2 , image 3 and Figure 5 , based on a transfer and blanking device and method for the production of numerically controlled electromechanical equipment provided by the first embodiment of the present application, the second embodiment of the present application proposes another transfer and blanking device and method for the production of numerically controlled electromechanical equipment. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0090] Specifically, the second embodiment of the present application provides a transfer and blanking device for the production of numerically controlled electromechanical equipment and a method thereof, which are different in that a transfer and blanking device for the production of numerically controlled electromechanical equipment and a method thereof, the placing ...

no. 3 example

[0100] Please refer to Figure 9 and Figure 10 , based on a transfer and blanking device and method for the production of numerically controlled electromechanical equipment provided by the first embodiment of the present application, the third embodiment of the present application proposes another transfer and blanking device and method for the production of numerically controlled electromechanical equipment. The third embodiment is only a preferred mode of the first embodiment, and the implementation of the third embodiment will not affect the independent implementation of the first embodiment.

[0101] Specifically, the third embodiment of the present application provides a transfer and blanking device for the production of numerically-controlled electromechanical equipment and a method thereof, which are different in that a transfer and blanking device for the production of numerically-controlled electromechanical equipment and a method thereof, the conveying One side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com