Cooling device applied to sample table

A technology of cooling device and sample stage, applied in the fields of single crystal growth, chemical instruments and methods, laboratory utensils, etc., can solve the problems of increasing operation difficulty and uncertainty, and achieve easy maintenance and replacement, reduce space requirements, save energy effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

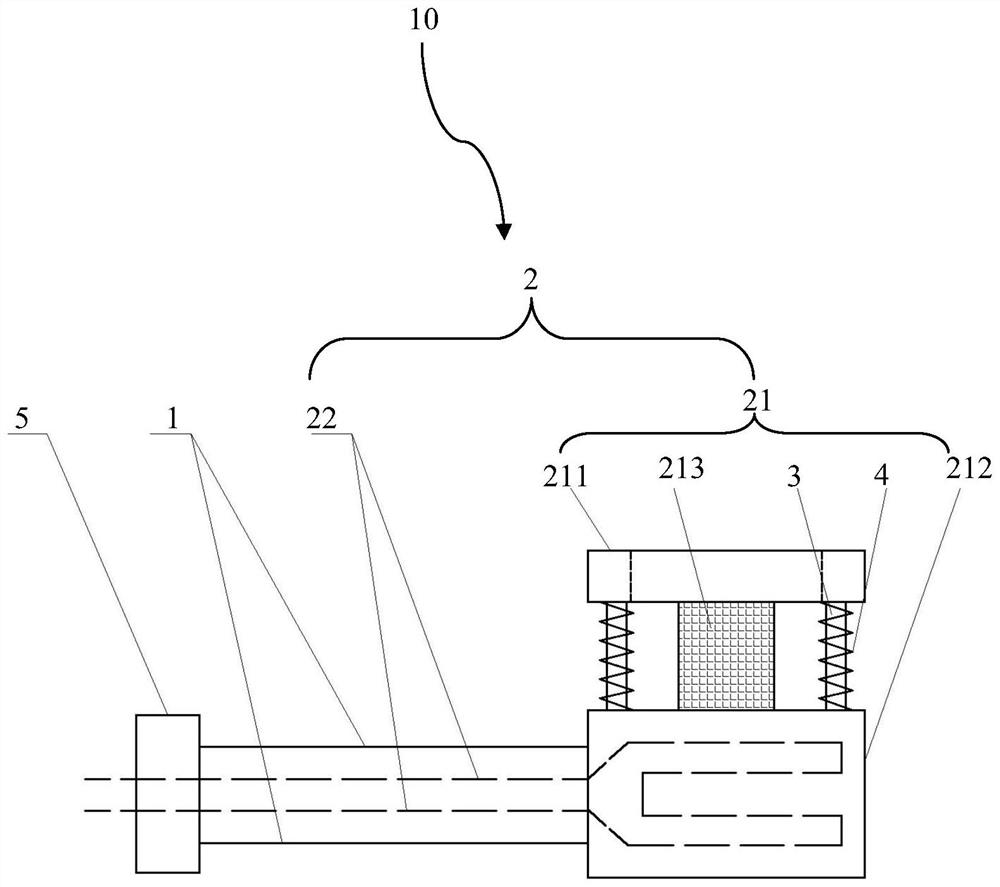

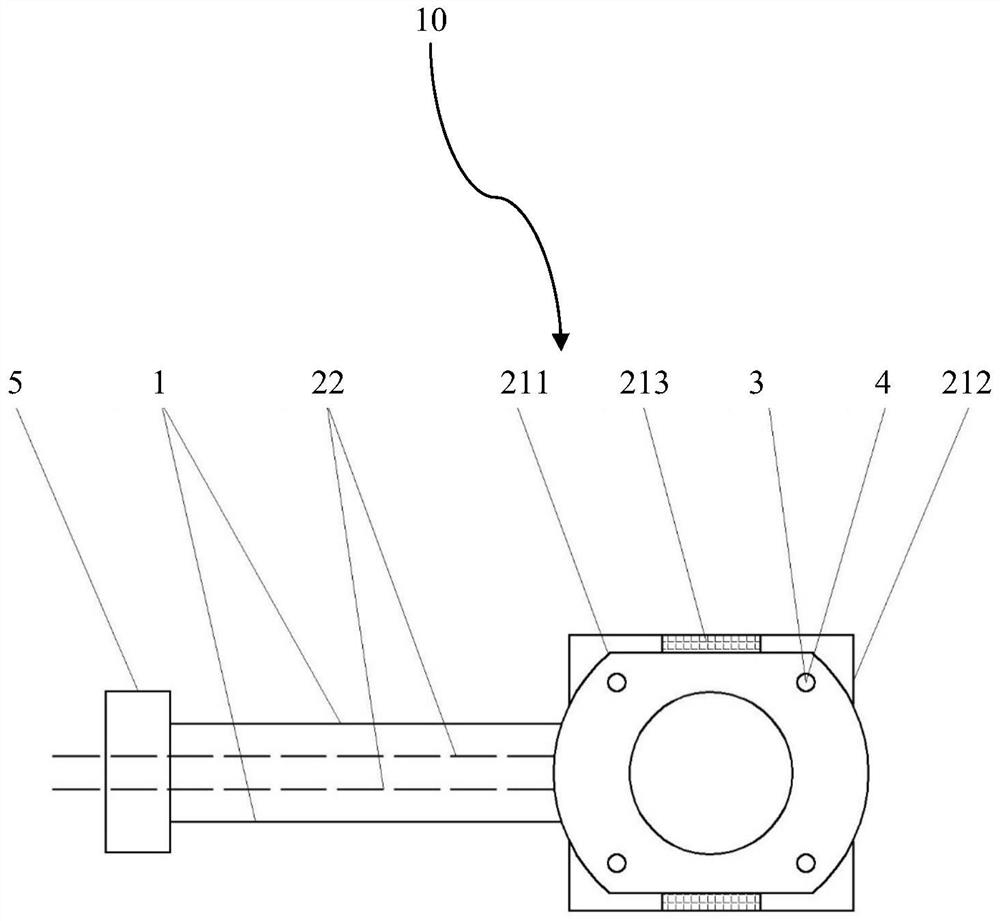

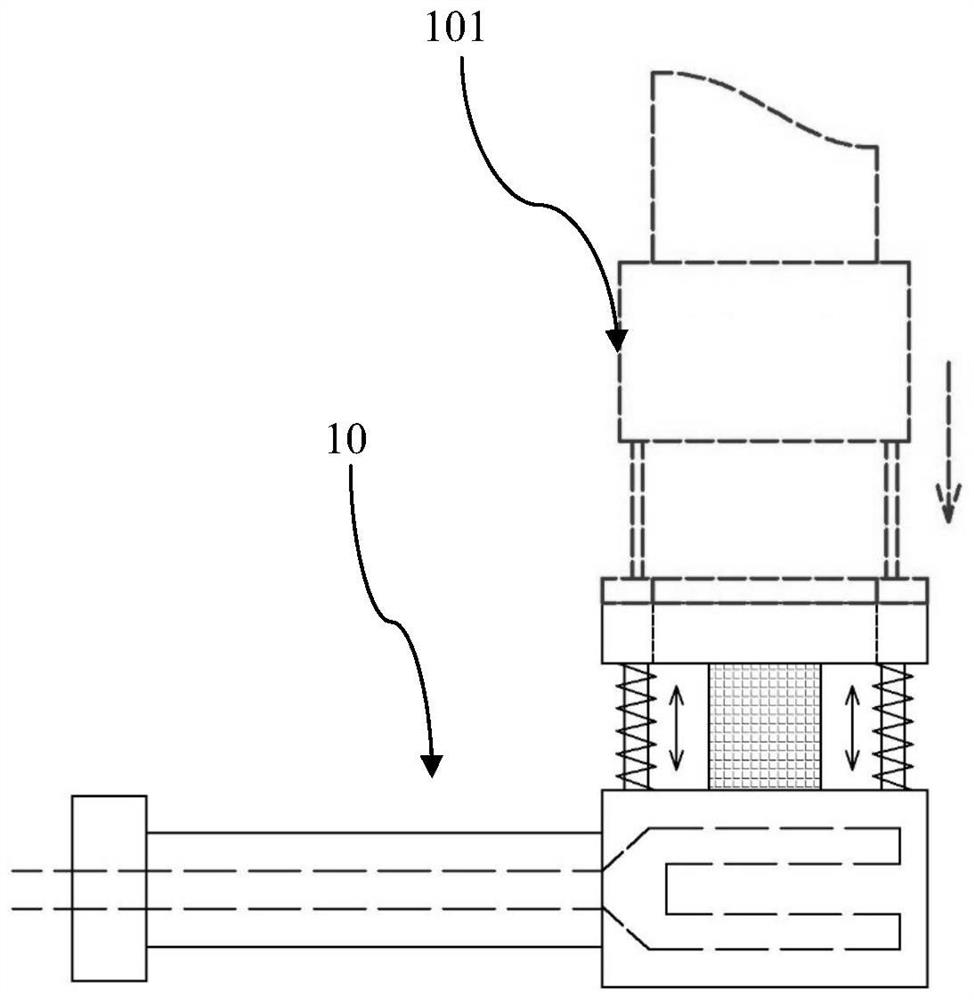

[0035] figure 1 The front view structure of the cooling device 10 according to the embodiment of the present invention is schematically shown; figure 2 The top view structure of the cooling device 10 according to the embodiment of the present invention is schematically shown; image 3 The assembly structure of the cooling device 10 and the sample stage 101 according to the embodiment of the present invention is schematically shown.

[0036] like Figure 1 to Figure 3 As shown, the cooling device 10 applied to the sample stage according to the embodiment of the present invention includes a connecting part 1 and a cooling assembly 2, wherein the top of the cooling assembly 2 has a supporting part that can be matched with the bottom of the sample stage 101, and on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap