Corrugated wall building and installation method thereof

A corrugated and wall technology, applied in the direction of architecture, building components, building structures, etc., can solve the problems of large components, large welding volume, large height and width, etc., to increase the overall rigidity, fast installation speed, and increased rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

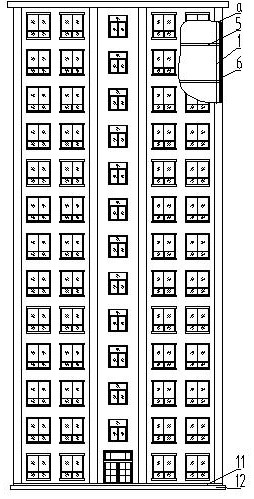

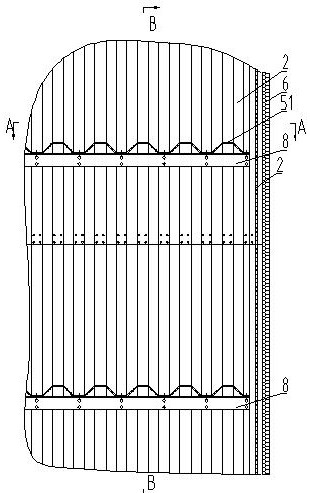

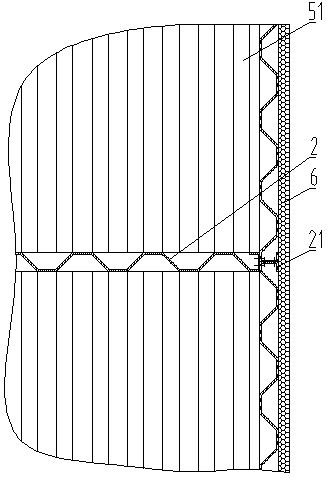

[0057] like figure 1 figure 2 image 3 As shown, the corrugated wall construction of the present invention comprises: a corrugated wall 1, the corrugated wall 1 includes a corrugated wallboard 2, and the corrugated wallboard is a trapezoidal corrugated wallboard, a groove-shaped corrugated wallboard or Concave-convex corrugated wall panels. The upper and lower adjacent corrugated wall panels 2 are overlapped and then connected by screw parts or through the transition piece 3 to form the heightened corrugated wall panels. The corrugated wall panels have no beams, and the corrugated wall panels without beams It can be produced directly through the assembly line, and the production and installation are very convenient, and the beam material and production cost can be saved. The left and right adjacent corrugated wall panels are connected by screws or welded to form the widened corrugated wall panels. In this connection, the width of the corrugated wall panels can be reduced, ...

Embodiment 2

[0059] The corrugated wall construction described in embodiment 1, such as Figure 16 , Figure 17 , Figure 18 , Figure 19 As shown, the upper part of the door and / or window has a plate body beam 7, and the plate body beam 7 is connected with the adjacent corrugated wallboard screw to form the door or window together, and the plate The body beam is a corrugated plate body beam 71 or a grooved plate body beam 72 . The slab beam of the present invention has the functions of the beam and the wall on the upper part of the traditional doorway and window.

Embodiment 3

[0061] The corrugated wall construction described in embodiment 1 or 2, such as figure 2 , Figure 4 , Figure 15 As shown, the side of the corrugated wall has a reinforcing beam 8, the floor slab 5 is installed on the reinforcing beam 8 or on the corrugated wall 1, and the corrugated wall panel 2 is a plane corrugated wall panel Or arc corrugated wallboard or right angle corrugated wallboard 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com