Roller fixing structure, vehicle window lifter and vehicle

A fixed structure and window lifting technology, which is applied to door/window accessories, building structures, power control mechanisms, etc., can solve problems such as high processing difficulty, affecting structural stability, and inability to contact the connecting ends at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

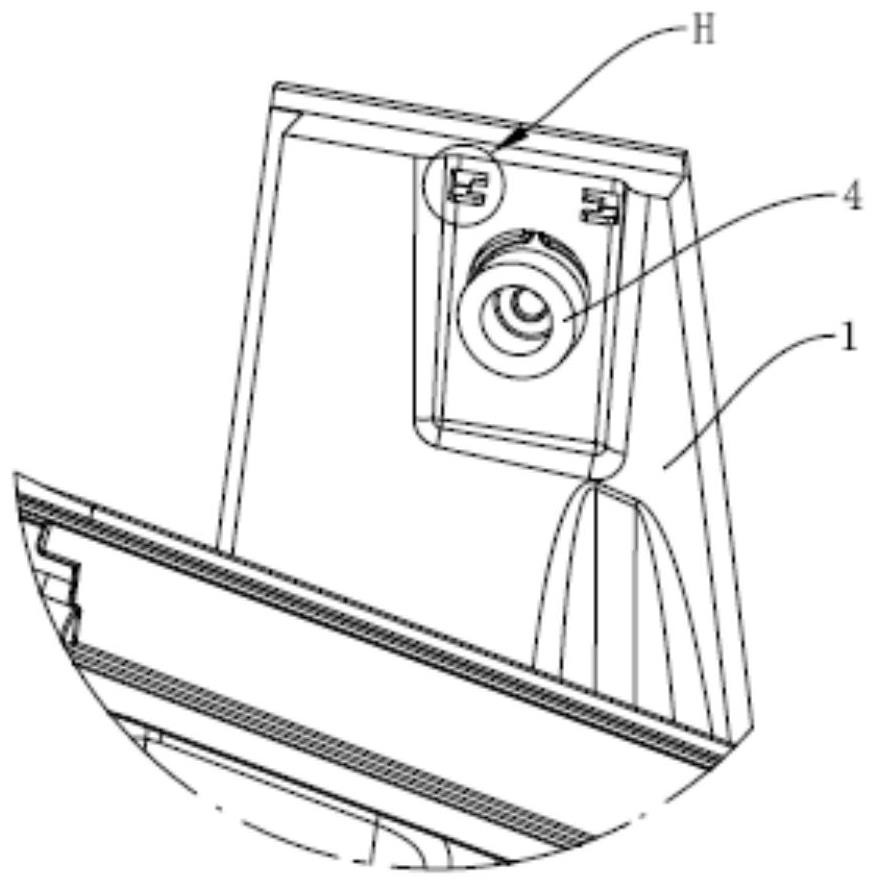

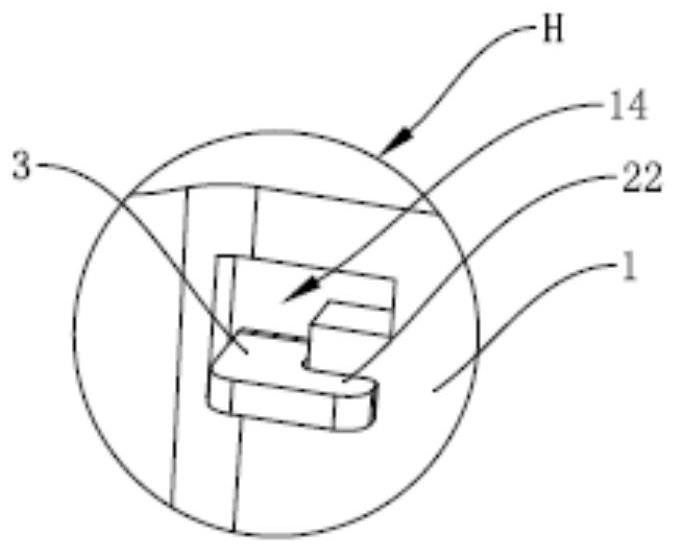

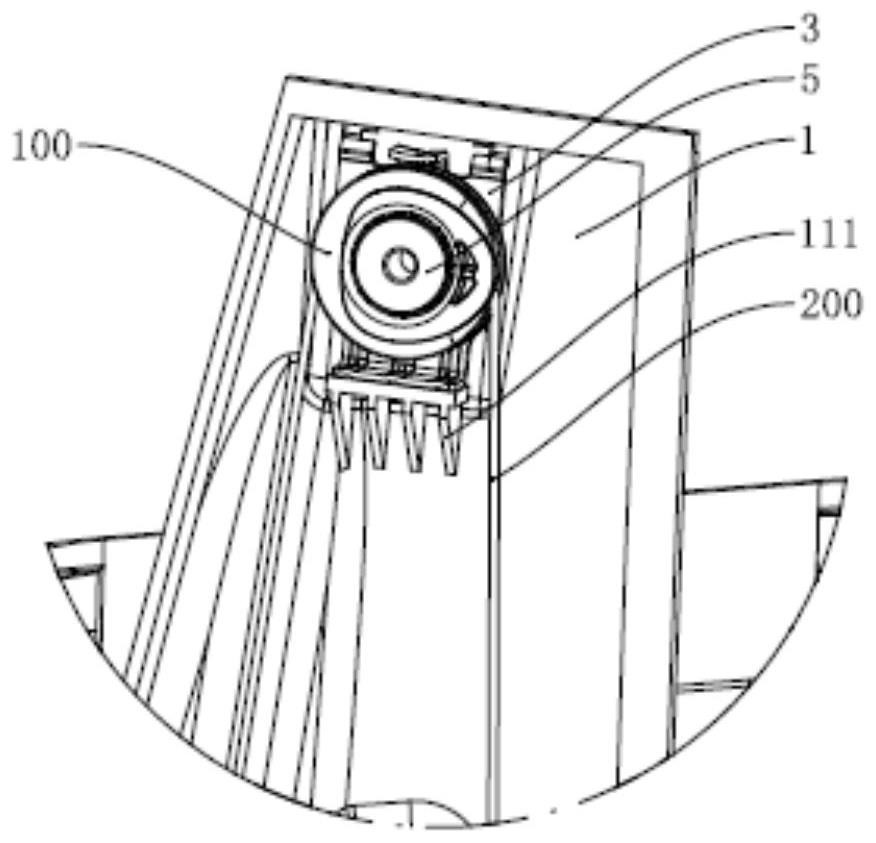

[0073] figure 1 A schematic diagram showing the structure of the roller fixing structure in the first embodiment of the present invention Figure 1 ; figure 2 Yes figure 1 Enlarged image at H in middle; image 3 A schematic diagram showing the structure of the roller fixing structure in the first embodiment of the present invention Figure II ; Figure 4 A schematic front view showing the roller fixing structure in Embodiment 1 of the present invention; Figure 5 Yes Figure 4 Cross-sectional schematic diagram of section A-A in the middle; Image 6 Yes Figure 5 Enlarged image at I. refer to Figure 1-Figure 6 , This embodiment provides a roller fixing structure, which is convenient for processing and can still be stably installed on the mounting plate when the support seat is deformed, which can be used in the technical field of window lifters.

[0074] continue to refer to Figure 1-Figure 6 , the roller fixing structure is used to install the roller 100 and the ...

Embodiment 2

[0086] Figure 7 A schematic structural diagram of the roller fixing structure in Embodiment 2 of the present invention is shown; Figure 8 A schematic front view showing the roller fixing structure in the second embodiment of the present invention; Figure 9 Yes Figure 8 Schematic cross-sectional view of the B-B section in the middle. refer to Figure 7-Figure 9 , this embodiment provides another roller fixing structure, which can also achieve the effect of the roller fixing structure in the first embodiment.

[0087] continue to refer to Figure 7-Figure 9 In this embodiment, the specific structures of the inserting block 61 and the slot 62, as well as the specific structures of the first abutting portion 11 and the third abutting portion 21 are the same as those in the first embodiment, and will not be repeated here. Different from the first embodiment, in this embodiment, the specific structure of the second abutting portion 12 and the fourth abutting portion 22 abut...

Embodiment 3

[0090] Figure 10 A schematic diagram showing the structure of the roller fixing structure in the third embodiment of the present invention Figure 1 ; Figure 11 Yes Figure 10 Enlarged image at J in middle; Figure 12 A schematic diagram showing the structure of the roller fixing structure in the third embodiment of the present invention Figure II ; Figure 13 A schematic front view showing the roller fixing structure in Embodiment 3 of the present invention; Figure 14 Yes Figure 13 Schematic cross-sectional view of the C-C section in the middle. refer to Figure 10-Figure 14 , this embodiment provides another roller fixing structure, which can also achieve the effect of the roller fixing structure in any of the above embodiments.

[0091] continue to refer to Figure 10-Figure 14 In this embodiment, the specific structures of the first abutting portion 11 and the third abutting portion 21 are the same as those in the first or second embodiment, and the specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com