Coaxial reciprocating motion mechanism and appliance

A reciprocating mechanism, coaxial technology, applied in electric components, transmission devices, electromechanical devices, etc., can solve the problems that the output end cannot automatically return, cannot form a coaxial output, and the pendulum bearing is large in size, and achieves low noise. , Simple structure, small sliding friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

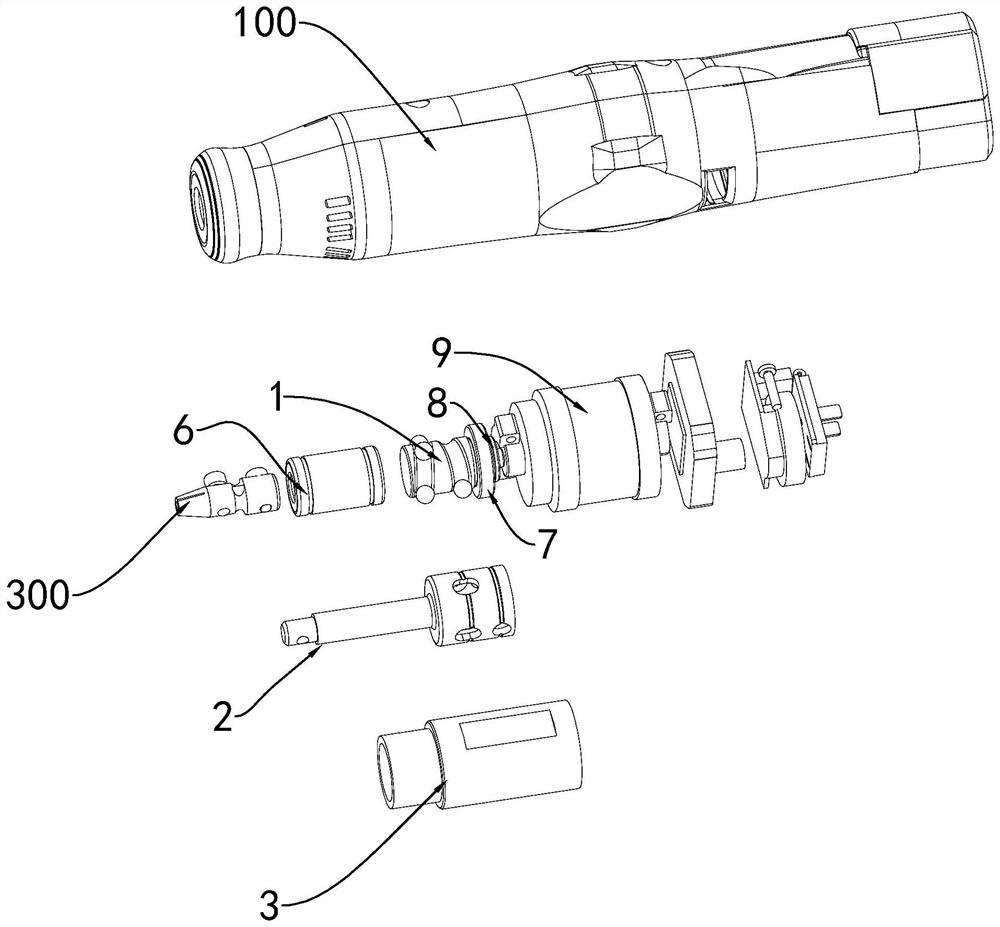

[0048] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Those skilled in the art will appreciate that these descriptions are descriptive, exemplary only, and should not be construed as limiting the scope of protection of the present invention.

[0049] It should be noted that like numerals refer to like items in the following figures, so once an item is defined in one figure, it may not be further defined and explained in subsequent figures.

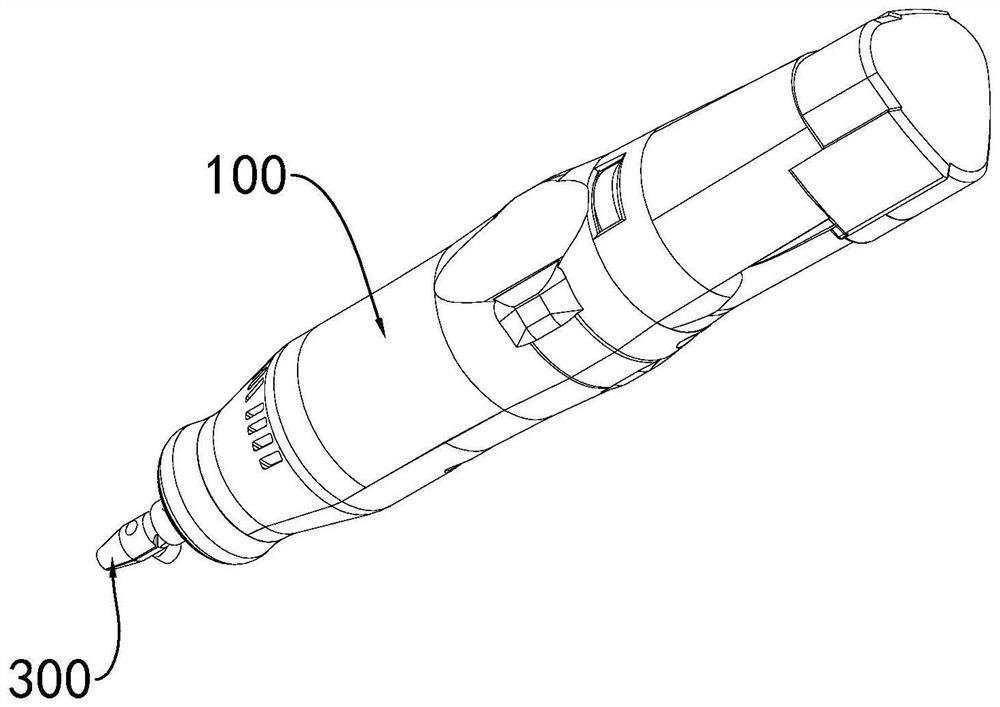

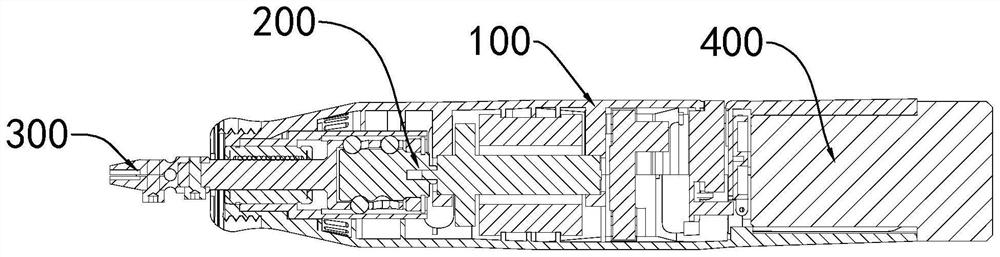

[0050] like Figure 1-3 As shown, this embodiment provides an electric file including a housing 100, a coaxial reciprocating mechanism 200 located in the housing 100, and a file connected to the front end of the coaxial reciprocating mechanism 200 and exposed at the front of the housing 100 Head 300. The movement of the coaxial reciprocating mechanism 200 makes the file head 300 move back and forth, so as to realize a straight line operation to file the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com