Modeling method of axial split-phase hybrid excitation type magnetic suspension motor

A technology of mixed excitation and axial phase separation, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electric components, etc., can solve problems such as incompatibility, different air gap lengths, and inaccurate models, and achieve good accuracy The effect of precision, accurate model and intuitive principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

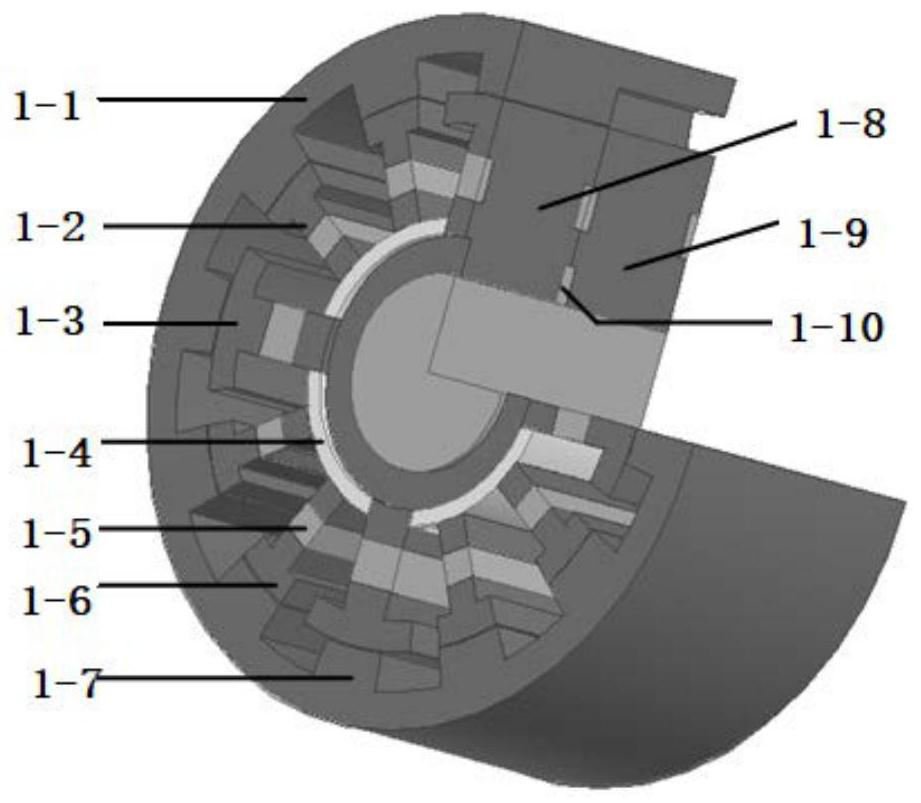

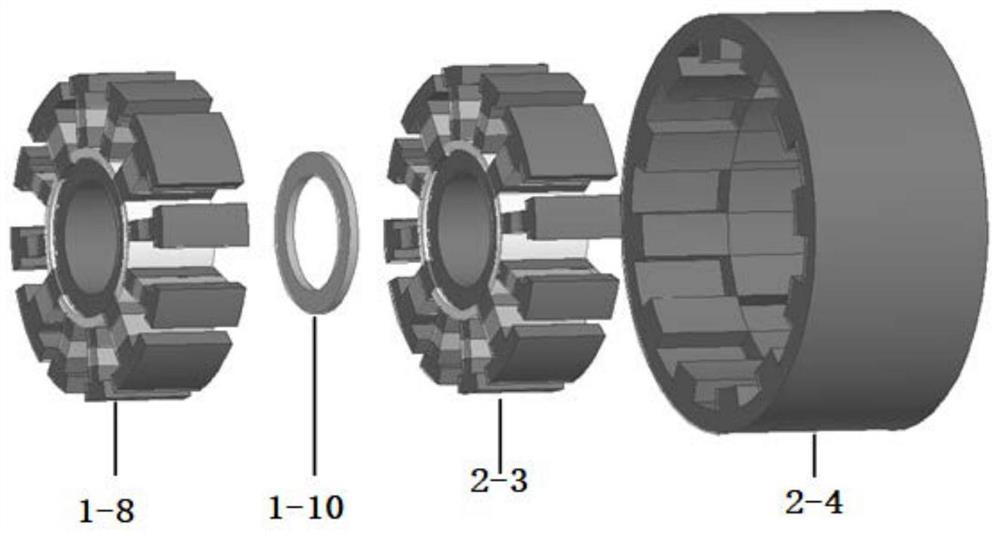

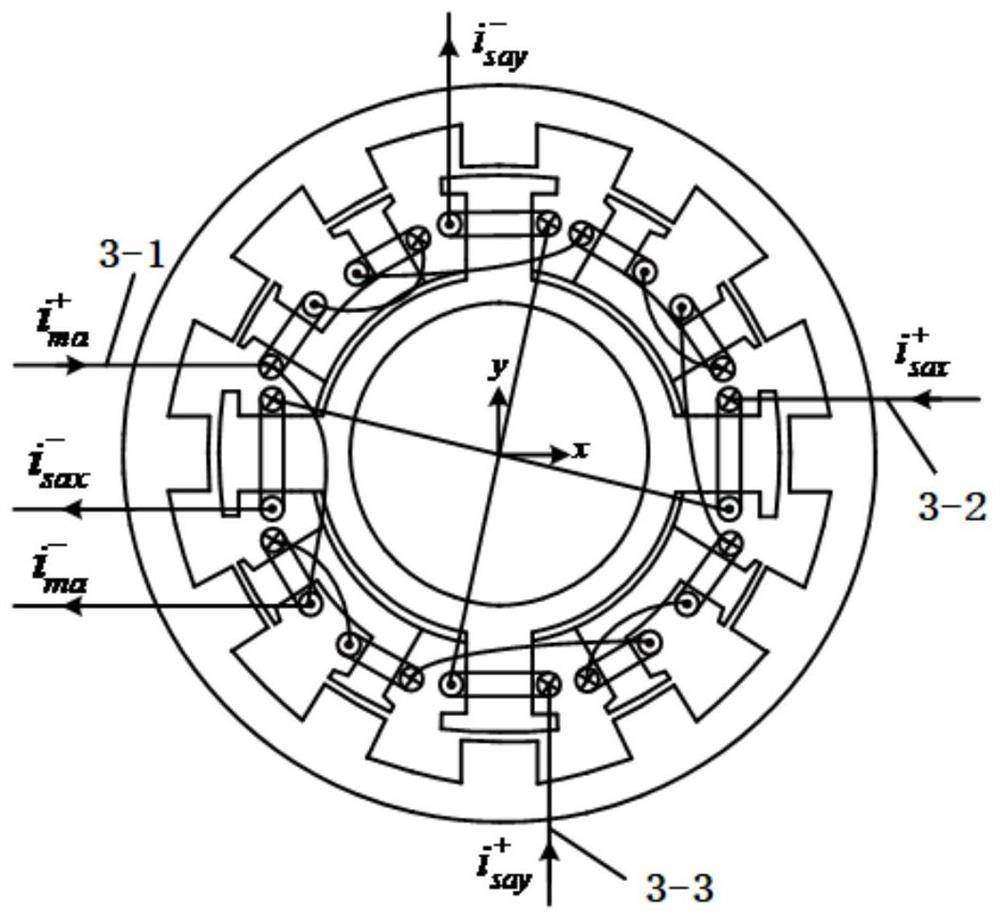

[0049] like figure 1 As shown, the axial split-phase hybrid excitation type magnetic suspension motor in the present invention includes an outer rotor 1-1, an inner stator 1-2, a suspension pole 1-3, a magnetic isolation ring 1-4, a winding 1-5, and a torque pole 1 -6. Rotor poles 1-7, A-phase stator cores 1-8, B-phase stator cores 1-9, and axially magnetized permanent magnets 1-10. Among them, the motor adopts the structure of an outer rotor and an inner stator; the outer rotor and the inner stator are divided into two phases, A and B, and the two phases are distributed along the axial direction, and the two phases have a high degree of symmetry in structure; the inner side of the outer rotor core of each phase is Twelve rotor poles are arranged at equal intervals along the circumference; there are eight narrow-tooth stator poles and four wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com