Internal rotational flow cross hole double-air-assisted ejector

A cross-hole and injector technology, applied in the direction of injection device, liquid injection device, etc., can solve the problems of poor fuel atomization effect and poor disturbance of the injector, improve the fluid mixing uniformity, reduce the spray particle size, and improve the Effects of mixing and jetting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

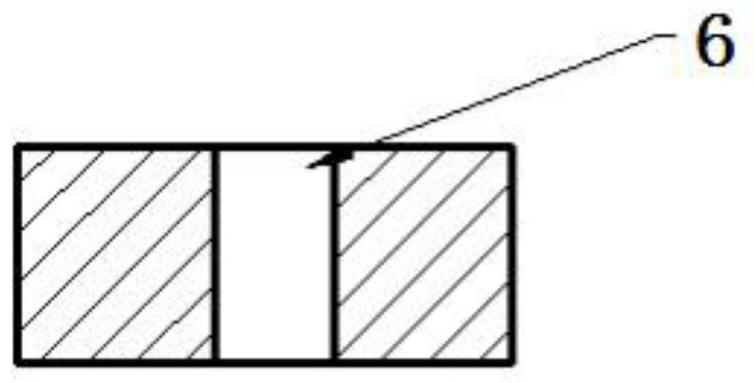

[0037] see Figure 1-14 , the embodiment of the present invention discloses an internal swirl cross-hole dual gas assisted injector, comprising: a main body 1, the main body 1 has a first cavity 2, a second cavity 3, a first channel 4, a second channel 5 and The third channel 6, the first cavity 2 is arranged on the first end face of the main body 1, the first cavity 2 is a blind hole arranged on the axis of the main body 1, the second cavity 3 is sleeved on the periphery of the first cavity 2, The first cavity 2 and the second cavity 3 are coaxially arranged, the side walls of the first cavity 2 and the second cavity 3 are communicated through the first channel 4, and the third channel 6 is arranged on the second end surface of the main body 1, And the third channel 6 communicates with the first cavity 2 , and the bottom end of the second cavity 3 communicates with the third channel 6 through the second channel 5 .

[0038] In the above embodiment, a plurality of first chann...

Embodiment 2

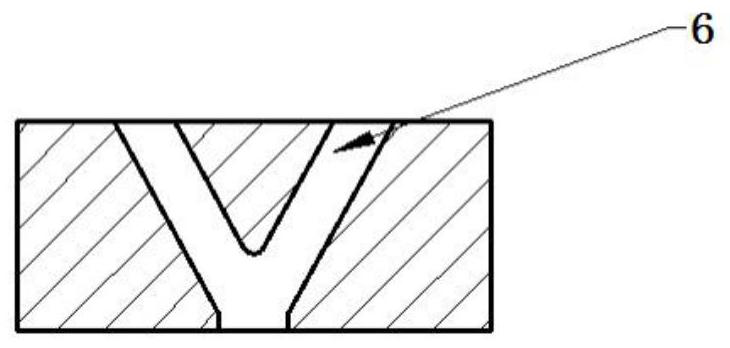

[0042] see Figure 15 , the rest of the structure is the same as the structure in Embodiment 1, the difference is that the setting method of the second channel 5 is different from that in Embodiment 1. In this embodiment, one end of the second channel 5 is communicated with the second cavity 3. Specifically Ground, one end of the second channel 5 is connected with the side wall of the second cavity 3, and the other end is communicated with the first cavity 2, the inclination angle of the second channel 5 is the same as the inclination angle of the third channel 6, and the second channel 5 is located in in the extension direction of the third channel 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com