Spot welding machine capable of adjusting spot welding angle for halogen lamp production and adjusting method

A halogen lamp, adjustable technology, applied in the direction of welding/welding/cutting items, welding equipment, resistance welding equipment, etc., can solve the problems of inconvenient welding needs, welding position deviation, adjustment of welding angle, etc., and achieve the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

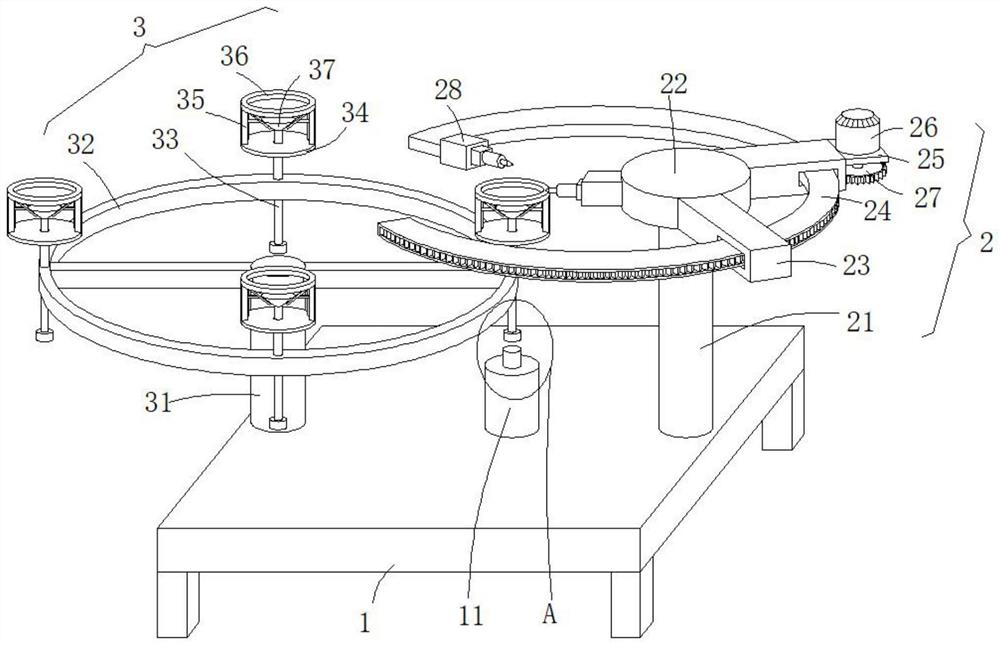

[0033] see Figure 1-3 , this embodiment provides a spot welding machine and an adjustment method with an adjustable welding angle for halogen lamp production, including a welding seat 1, a transmission mechanism 2 for installing the upper and lower electrodes of the spot welding machine, and a material loading mechanism 3 , the transmission mechanism 2 is arranged on the upper end side of the welding seat 1, and the welding seat 1 vacates the transmission mechanism 2 to adjust the spot welding positions of the upper electrode and the lower electrode of the spot welding machine to meet the requirements of the upper electrode and the lower electrode of the spot welding machine. Electrode precise spot welding requirements.

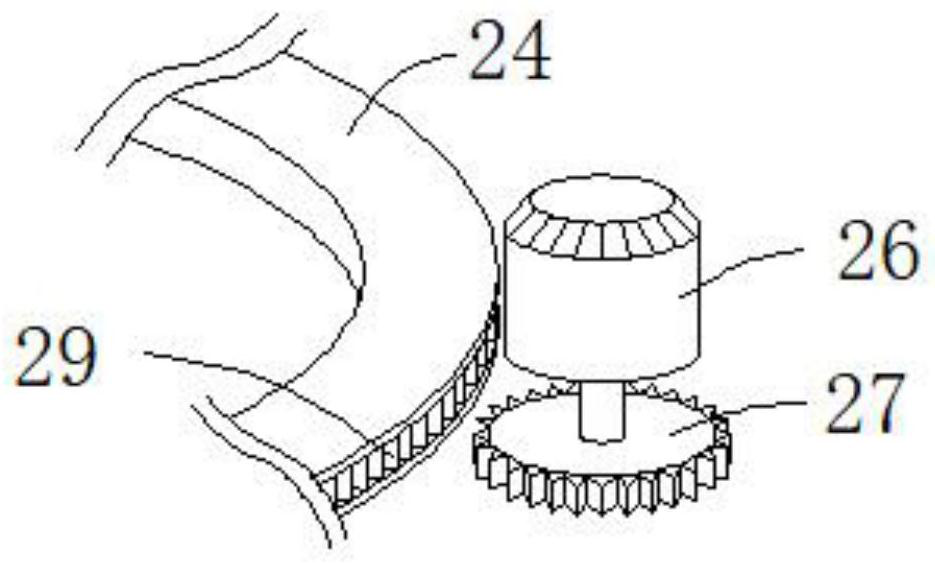

[0034]The transmission mechanism 2 includes a first column 21 and a transmission frame 24. The first column 21 is fixed on one side of the upper end of the welding seat 1 and a tray 22 is fixed at the top of the first column 21. The transmission frame 24 is ...

Embodiment 2

[0043] see figure 1 , figure 2 and Figure 4 , made further improvements on the basis of Example 1:

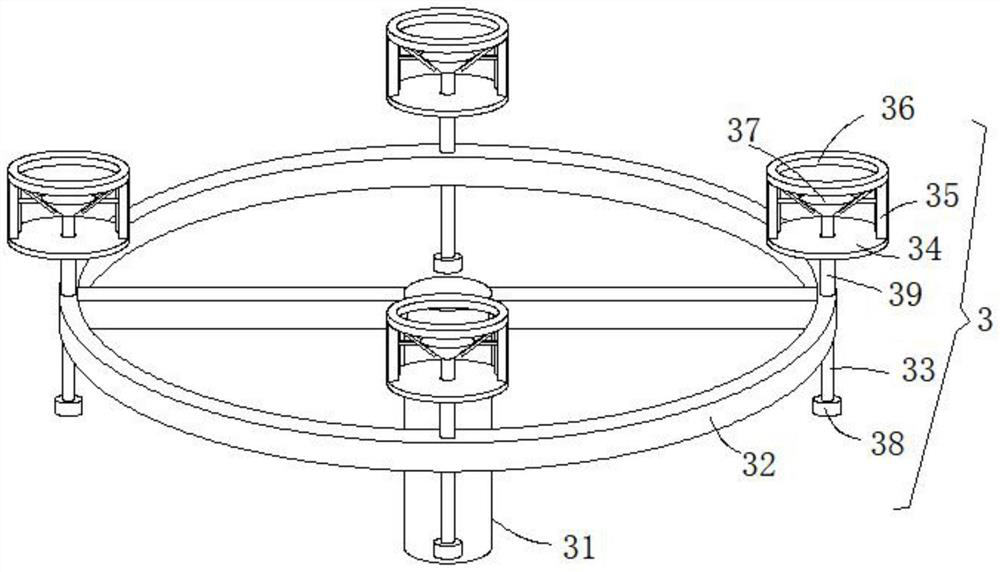

[0044] Prevent the halogen lamp on the support plate 34 from being easily separated from the support plate 34 by the centrifugal force generated by the rotation of the annular support frame 32 in the state without peripheral protection, which is easy to cause the halogen lamp to fall and break, and also affects the efficient welding operation of the halogen lamp. In order to prevent the halogen lamp from falling off the support plate 34 during the transmission process, two support rods 35 are symmetrically arranged on the upper end of the support plate 34 and a protective frame 36 is fixed between the top ends of the two support rods 35. The protective frame 36 is vacated and used as a protective fence. When the halogen lamp to be welded is placed on the support plate 34, the protective frame 36 is used to protect and support the periphery of the halogen lamp to prevent the...

Embodiment 3

[0048] see figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 , made further improvements on the basis of Example 2:

[0049] A support sleeve 39 is fixed at the bottom end of the support plate 34 , and the support sleeve 39 is fixed on the upper end surface of the annular support frame 32 , and the support plate 34 is stably supported on the upper end surface of the annular support frame 32 by the support sleeve 39 , to ensure that when the annular support frame 32 rotates with the second column 31 as the center, the support plate 34 can also make a circular motion with the second column 31 as the center, so as to realize the orderly transmission of the halogen lamp to be welded.

[0050] After the halogen lamp is welded, in order to facilitate taking out the halogen lamp from the protective frame 36, a guide rod 33 is slidably penetrated through the middle-shaped through hole in the support sleeve 39, and the top of the guide rod 33 slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com