Single-component polyurethane foam joint mixture and preparation method thereof

A technology of polyurethane foam and caulking agent, which is applied in the fields of botanical equipment and methods, biocides, disinfectants, etc., can solve the problems of rooting and post-foaming that are not mentioned, so as to improve the utilization rate of fertilizers and promote vigorous growth. , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

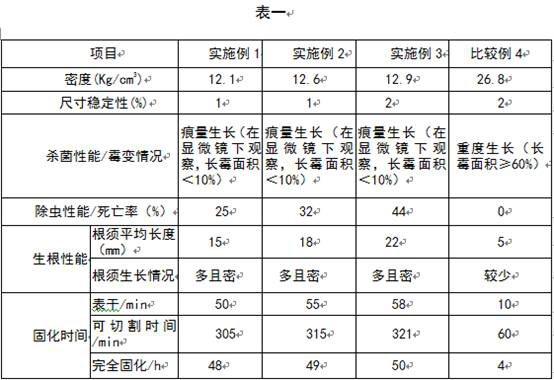

Examples

Embodiment 1

[0034] According to the proportion by weight, 0.5 part of indole butyric acid, 0.5 part of naphthalene acetic acid, and 0.5 part of gibberellin are mixed in proportion, and the rooting agent is obtained by microencapsulation; 0.5 part of dihydroxy-5,5'-dichlorodiphenylmethane, 0.5 part of 2,4,4'-trichloro-2'-hydroxydiphenyl ether, 0.5 part of silver ion-containing zirconium phosphate-based ceramic ion exchange resin and mixed to obtain a fungicide.

[0035] According to the weight distribution ratio, 36 parts of seed wrap wax, 2 parts of Yukol1030 polyether polyol, 5 parts of Voranol2070 polyether diol, 1 part of L-626 foam stabilizer, and 1 part of L-627 foam stabilizer were added to the reaction kettle in turn. , 0.5 part of DabcoBL-17 delayed catalyst, 0.5 part of Toyocat-NCD delayed catalyst, 1.5 part of fungicide, 1 part of camphor powder, 1 part of insecticide amidine, 1.5 part of rooting agent, stir well, and then the combined polyether can be prepared; press A certain...

Embodiment 2

[0037] According to the proportion by weight, 1 part of indole butyric acid, 1 part of naphthalene acetic acid, and 1 part of gibberellin are mixed in proportion, and the rooting agent is obtained after microencapsulation; - 1 part of dihydroxy-5,5'-dichlorodiphenylmethane, 1 part of 2,4,4'-trichloro-2'-hydroxydiphenyl ether, zirconium phosphate-based ceramic ion exchange resin containing silver ions 1 part was mixed to obtain a fungicide.

[0038] According to the weight distribution ratio, 39 parts of seed wrap, 3 parts of Yukol1030 polyether polyol, 6 parts of Voranol2070 polyether diol, 1.5 parts of L-626 foam stabilizer, 1.5 parts of L-620 foam stabilizer, 1 part of DabcoBL-17 delayed catalyst, 1 part of NiaxEF-700 delayed catalyst, 3 parts of bactericide, 1.5 parts of camphor powder, 1.5 parts of calcium arsenate, 3 parts of rooting agent, mix well, and then the combined polyether can be prepared; Proportion The combined polyether, 21 parts of polymerized MDI, 10 parts ...

Embodiment 3

[0040] According to the proportion by weight, 1.5 parts of indole butyric acid, 1.5 parts of naphthalene acetic acid, and 1.5 parts of gibberellin were mixed in proportion, and the rooting agent was obtained after microencapsulation; 1.5 parts of dihydroxy-5,5'-dichlorodiphenylmethane, 1.5 parts of 2,4,4'-trichloro-2'-hydroxydiphenyl ether, 1.5 parts of silver ion-containing zirconium phosphate-based ceramic ion exchange resin and mixed to obtain a fungicide.

[0041] According to the weight distribution ratio, 42 parts of seed wrap wax, 4 parts of Yukol1030 polyether polyol, 7 parts of Voranol2070 polyether diol, 2 parts of L-626 foam stabilizer, and 2 parts of L-620 foam stabilizer were added to the reaction kettle in turn. , 1.5 parts of Toyocat-NCD delay catalyst, 1.5 parts of NiaxEF-700 delay catalyst, 4.5 parts of bactericide, 2 parts of insecticide, 2 parts of calcium arsenate, 4.5 parts of rooting agent, mix well, and then the combined polyether can be obtained; The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com