Chemical mechanical polishing solution for tungsten polishing

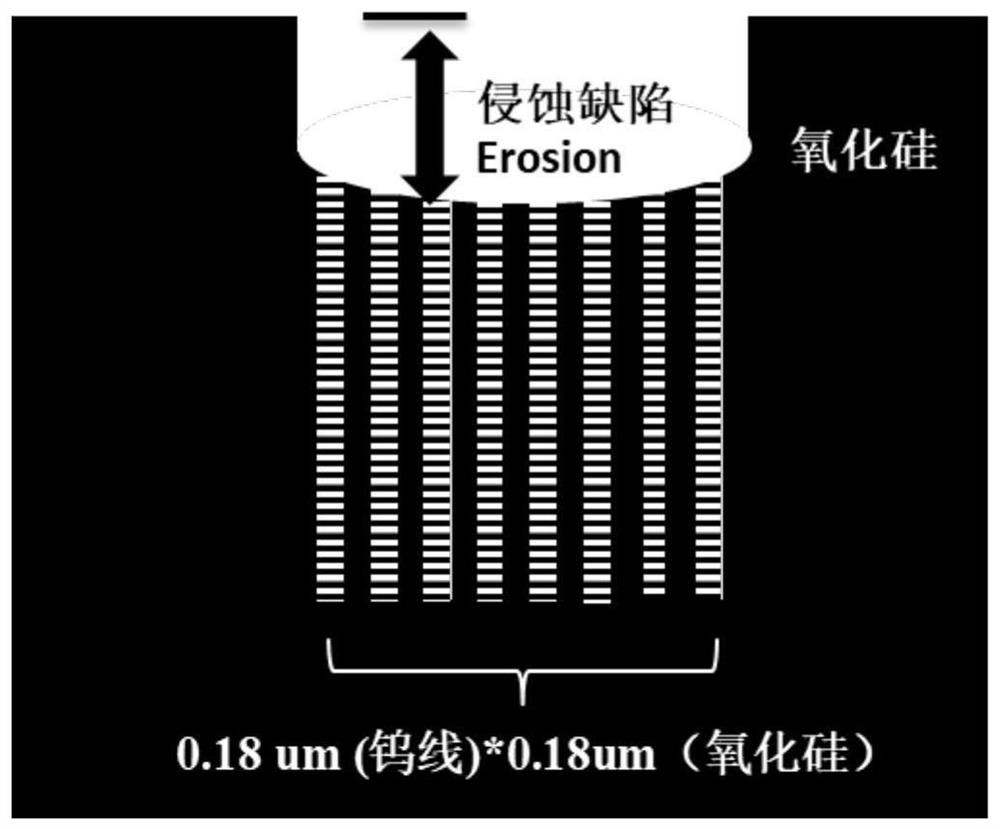

A chemical-mechanical and polishing liquid technology, applied in polishing compositions containing abrasives, etc., can solve the problems of high static corrosion rate of tungsten surface, inability to protect tungsten surface well, and deep erosion defects, etc. The effect of improving erosion defects and increasing the static corrosion rate ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The advantages of the present invention are further described below with reference to the accompanying drawings and specific embodiments.

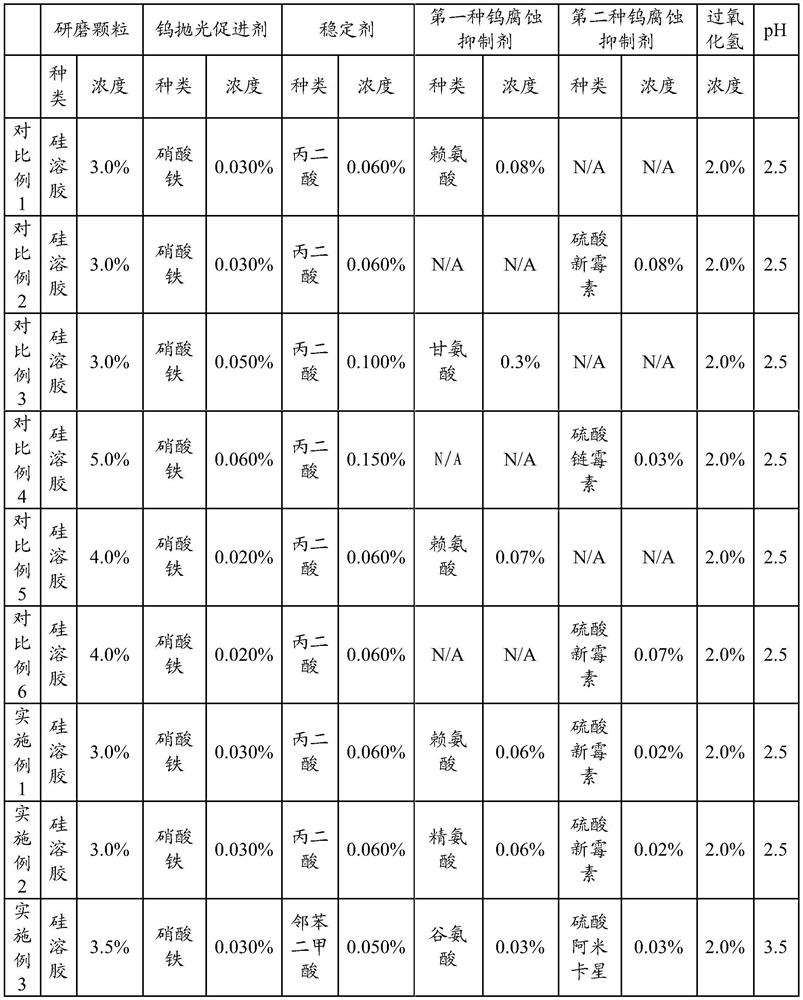

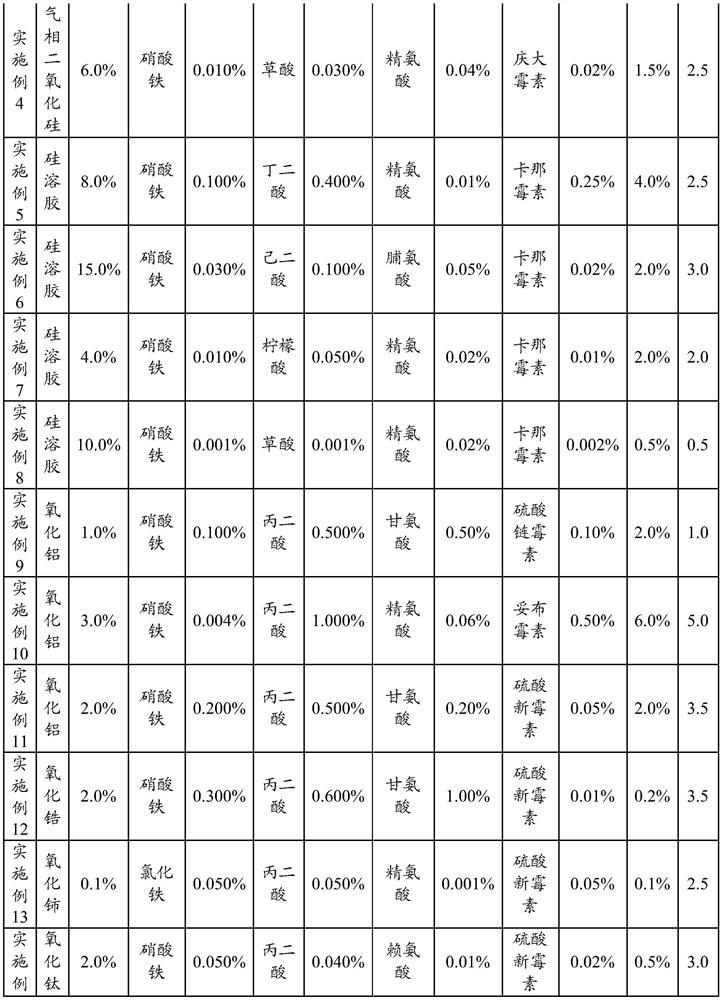

[0029] Table 1 shows the formulations of chemical mechanical polishing solutions of the present invention for Examples 1 to 17 and Comparative Examples 1 to 6. According to the components and their contents listed in Table 1, they are evenly mixed in deionized water, and the pH regulator nitric acid is used to mix them evenly. Alternatively, potassium hydroxide can be adjusted to the required pH value, and then the chemical mechanical polishing liquid examples or comparative examples of the present invention can be prepared.

[0030] Table 1 The formula of chemical mechanical polishing liquid embodiment 1-17 of the present invention and comparative example 1-6

[0031]

[0032]

[0033]

[0034] The tungsten wafers were polished with the polishing solution mixed with the formula in Table 1 according to the following experim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com