Chemical mechanical polishing size

A polishing slurry and oxidant technology, applied in other chemical processes, chemical instruments and methods, polishing compositions containing abrasives, etc., can solve the problems of insufficient polishing speed, residual, and overall corrosion static corrosion rate, etc., to reduce static The effect of corrosion rate

Active Publication Date: 2015-05-27

ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

View PDF13 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above-mentioned polishing slurry for copper has insufficient polishing speed, and there are defects, scratches, stains and copper residues on the substrate surface after use, or the depression of the copper block after polishing is too large, or there are defects in the polishing process. Problems such as local or overall corrosion and high static corrosion rate of copper at room temperature and polishing temperature (such as 50°C)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

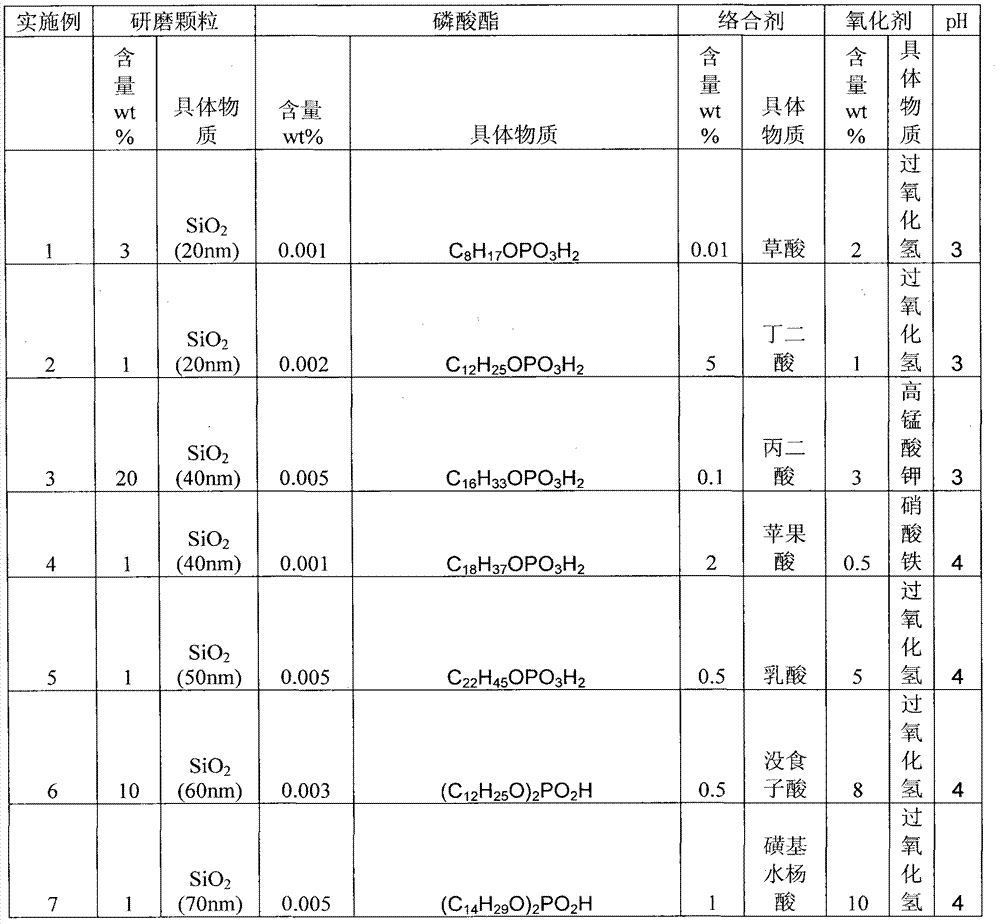

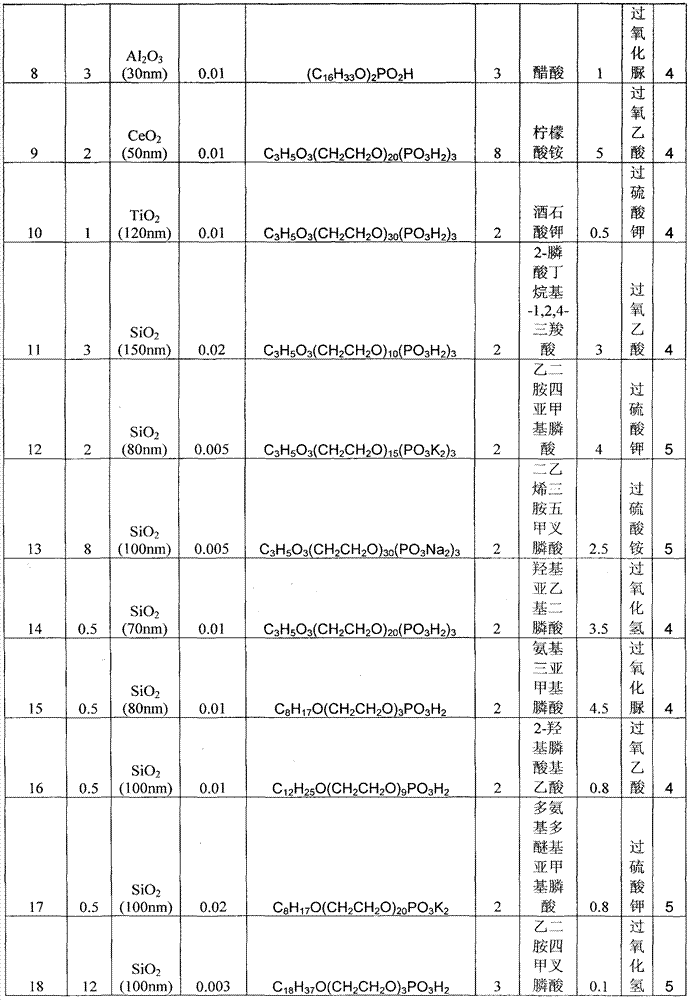

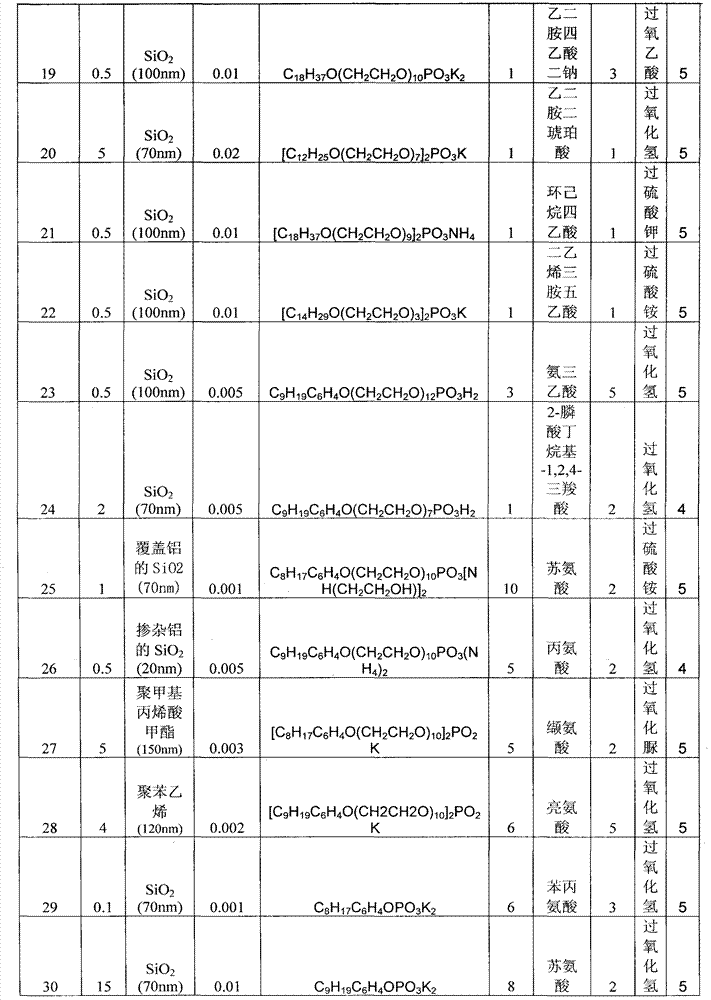

Embodiment 1~47

[0021] Table 1 shows Examples 1-47 of the chemical mechanical polishing solution of the present invention. According to the formula given in the table, the other components except the oxidizing agent are mixed evenly, and the mass percentage is made up to 100% with water. with KOH or HNO 3 Adjust to desired pH. Add oxidant before use and mix evenly.

[0022] Table 1 Examples 1-47

[0023]

[0024]

[0025]

[0026]

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

A chemical mechanical polishing slurry for use in copper, comprising at least a phosphate ester surfactant as well as grinding particles, a complexing agent and an oxidizing agent. Using the slurry in the present invention can decrease the static erosion rate of copper, suppress the removing rate of copper at low pressures and reduce the disc-shaped depressions after polishing.

Description

technical field [0001] The present invention relates to a chemical mechanical polishing slurry for copper. Background technique [0002] With the development of microelectronics technology, the integration of very large scale integrated circuit chips has reached billions of components, and the feature size has entered the nanometer level, which requires hundreds of processes in the microelectronics process, especially multi-layer wiring, Substrates and media must undergo chemical mechanical planarization. VLSI wiring is being transformed from traditional Al to Cu. Compared with Al, Cu wiring has low resistivity, high electromigration resistance, and short RC delay time. The advantages of Cu wiring have made it replace Al as an interconnect metal in semiconductor manufacturing. However, there is no known technology for effectively plasma etching or wet etching copper material to fully form copper interconnections in integrated circuits, so chemical mechanical polishing of c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09G1/02

CPCC09G1/02C09K3/1463H01L21/3212

Inventor 荆建芬蔡鑫元张建

Owner ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com