Mask for packaging four-side pin-free flat semiconductor

A semiconductor, leadless technology, used in semiconductor devices, semiconductor/solid-state device parts, film/sheet adhesives, etc. Sliding improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

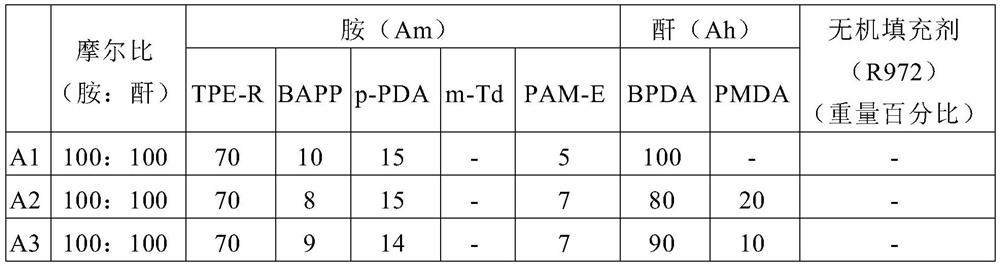

[0079] 1. Manufacture of adhesive layer

[0080] Adhesive layers for mask sheets were fabricated as shown in Table 1 below.

[0081] A varnish was prepared using the polyimide resin of the following molar ratio to prepare a preparation liquid for an adhesive layer.

[0082] Table 1

[0083]

[0084] *TPE-R: 1,3'-bis(4-aminophenoxy)benzene

[0085] *BAPP: 2,2-bis[4-(4-aminophenoxy)phenyl]propane

[0086] *p-PDA: p-phenylenediamine

[0087] *m-Td: 4,4'-diamino-2,2'-dimethylbiphenyl

[0088] *PAM-E: Amino-modified reactive silicone oil (manufactured by Shinetsu silicone)

[0089] *BPDA: 3,3',4,4'-biphenyltetracarboxylic dianhydride

[0090] *PMDA: pyromellitic dianhydride

[0091] *R972: 972 (manufactured by Evonik)

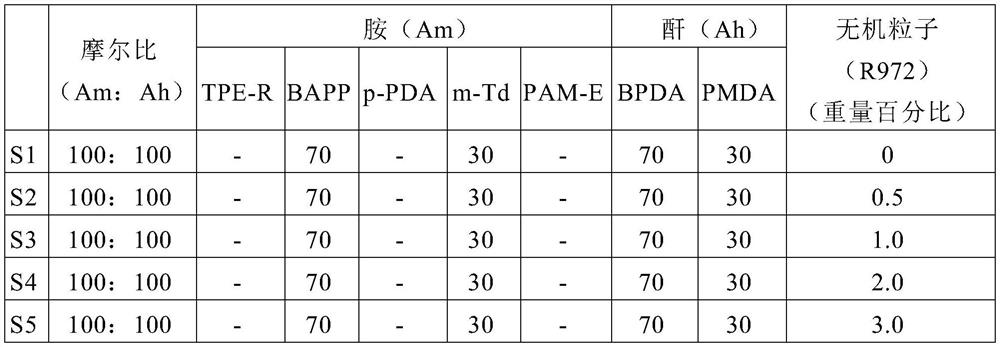

[0092] 2. Manufacture of reinforcement layer

[0093] Reinforcing layers for mask sheets were fabricated as shown in Table 2 below.

[0094] A varnish was prepared using the polyimide resin of the following molar ratio, thereby preparing a preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com