High-strength and high-plasticity six-element eutectic high-entropy alloy and preparation method thereof

A high-plastic six-element eutectic and high-entropy alloy technology, applied in the field of high-entropy alloys, can solve problems such as single system, imperfect heat treatment process, and small number of components, and achieve uniform structure, simple and reliable melting and annealing process , the effect of less casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

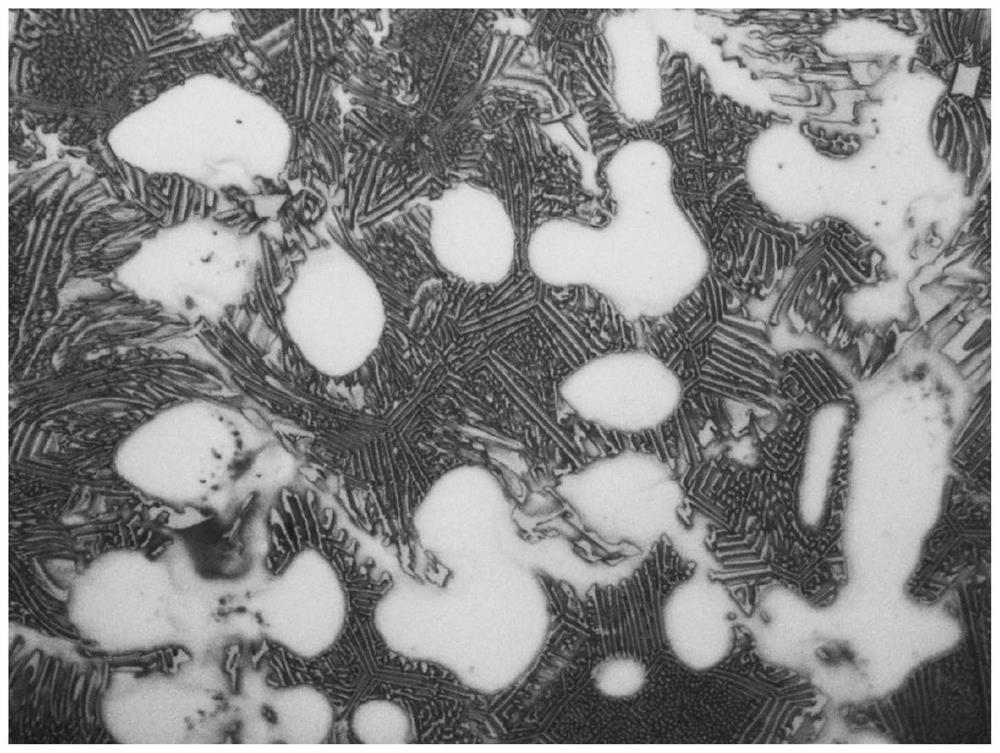

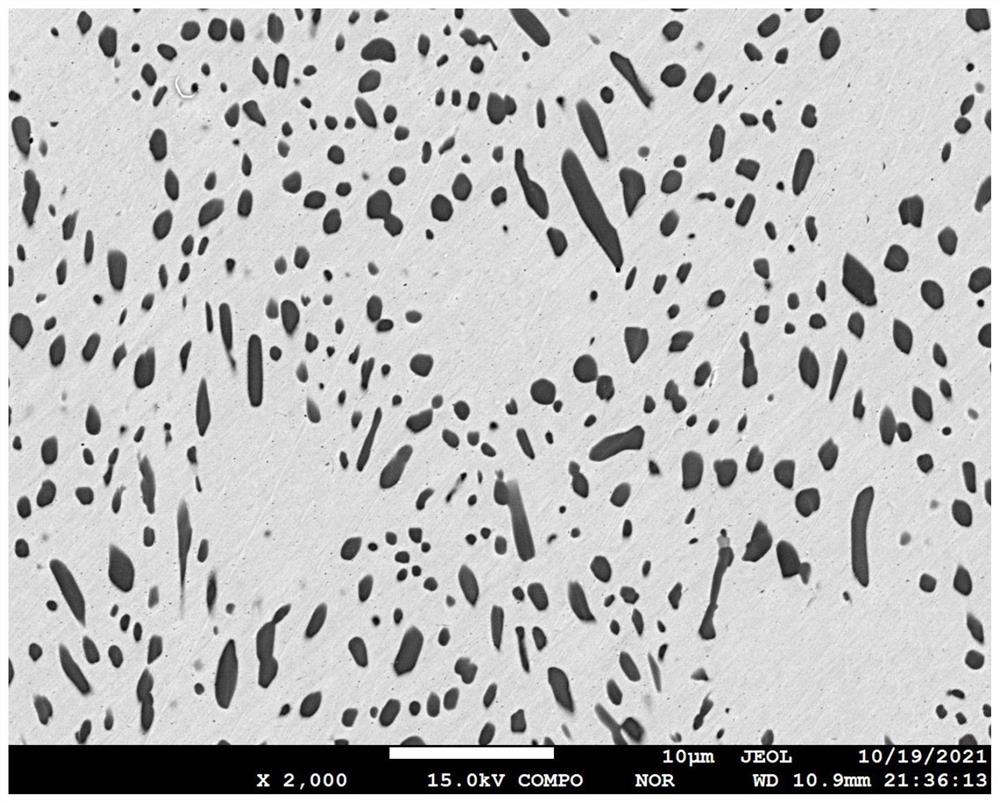

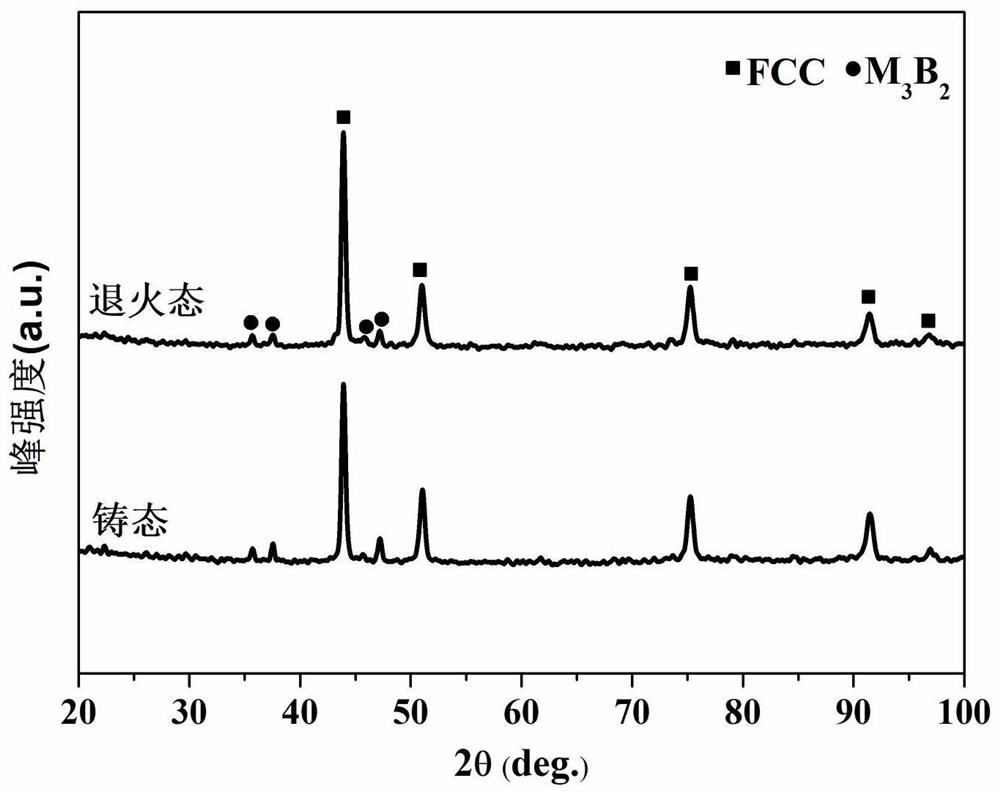

[0036] This embodiment discloses a high-strength and high-plastic hexagonal eutectic high-entropy alloy whose general formula is CoCrNi 2 V 0.48 B 0.32 Si 0.16 Hypoeutectic high-entropy alloy composition.

[0037] In the present embodiment, the steps of a preparation method of a high-strength and high-plastic hexagonal eutectic high-entropy alloy are as follows:

[0038]Step 1. Use SiC sandpaper to grind Co, Cr, Ni and V gold with a purity of 99.95wt.% metal elemental raw materials to remove the oxide scale and impurities on the surface, then place them in different containers, add alcohol, and carry out ultrasonic cleaning; For B and Si non-metallic raw materials with a purity of 99.99 wt.%, only ultrasonic cleaning is performed without participating in the surface grinding process. After the cleaned elemental raw materials are fully dried, put them into sealed bags separately for use;

[0039] Step 2. Convert based on the element molar ratio to the mass ratio, and based...

Embodiment 2

[0045] This embodiment discloses a high-strength and high-plastic hexagonal eutectic high-entropy alloy whose general formula is CoCrNi 2 V 0.63 B 0.42 Si 0.21 Fully eutectic high-entropy alloy composition.

[0046] In the present embodiment, the steps of a preparation method of a high-strength and high-plastic hexagonal eutectic high-entropy alloy are as follows:

[0047] Step 1. Use SiC sandpaper to polish the pure metal raw materials Co, Cr, Ni and V gold with a purity of 99.95wt.% to remove the oxide scale and impurities on the surface, then place them in different containers, add alcohol, and carry out ultrasonic cleaning ; For B and Si non-metallic raw materials with a purity of 99.99wt.%, only ultrasonic cleaning is performed without participating in the surface grinding process. After the cleaned elemental raw materials are fully dried, put them into sealed bags separately for use;

[0048] Step 2. Convert based on the element molar ratio to the mass ratio, and ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com